A kind of polysiloxane based on aromatic disulfide bond and its application

A polysiloxane and disulfide bond technology is applied in the application field of preparing lithium battery positive electrode materials, which can solve the problems of easy reaction with electrolyte, poor material hydrophobicity, unstable imine bond, etc., and achieves recovery of mechanical properties, Good stretchability, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

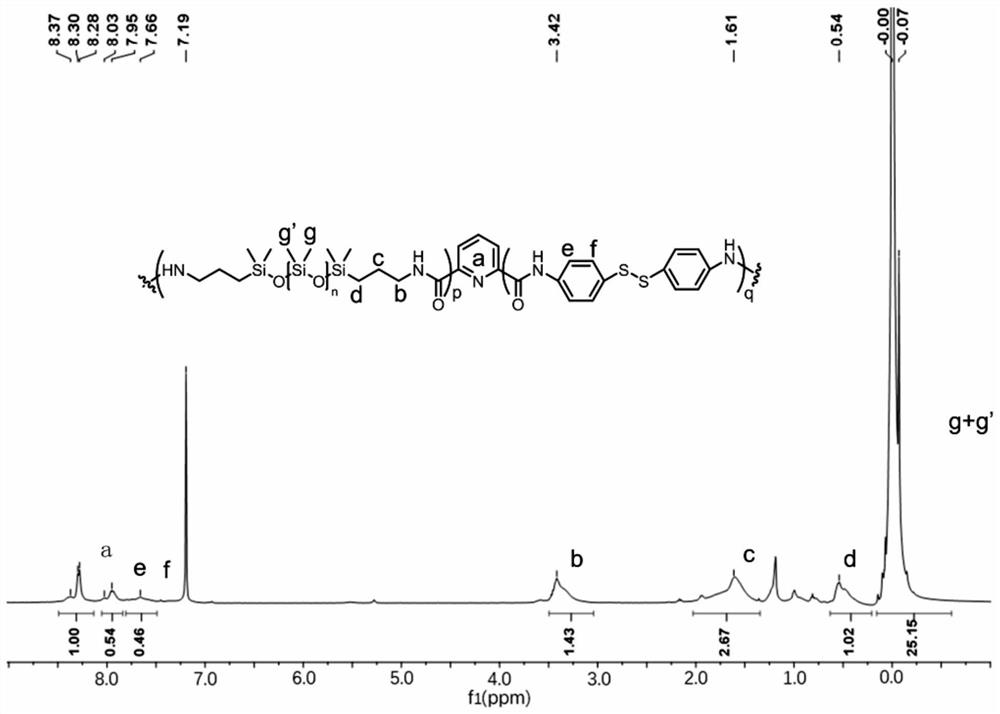

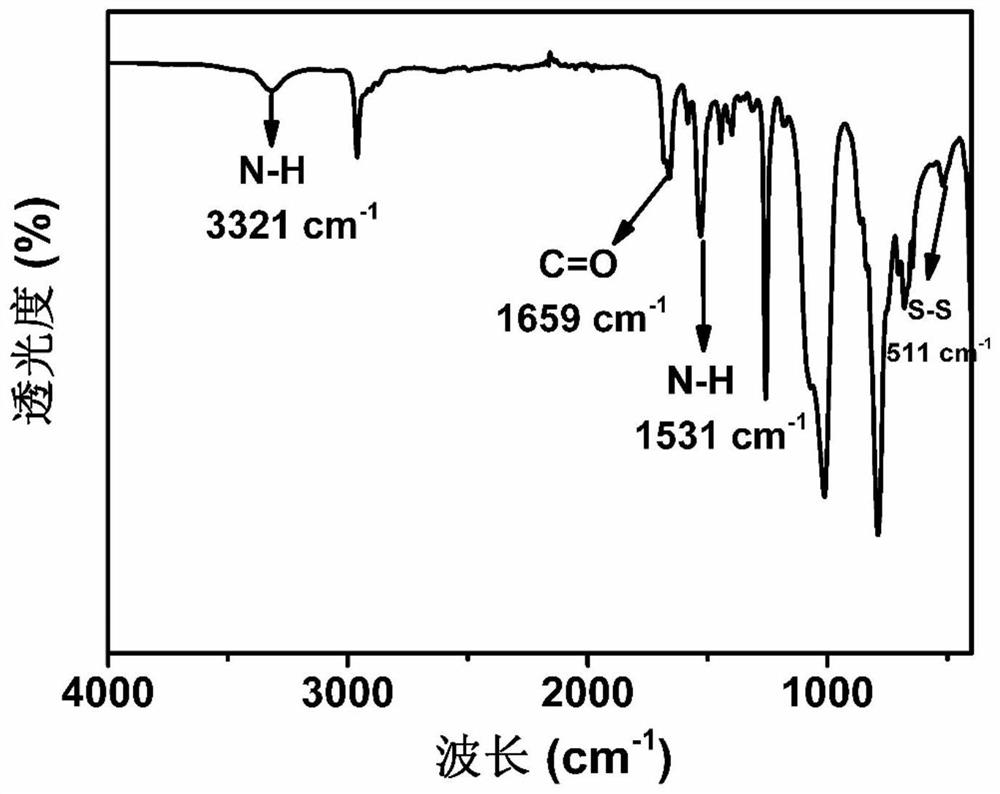

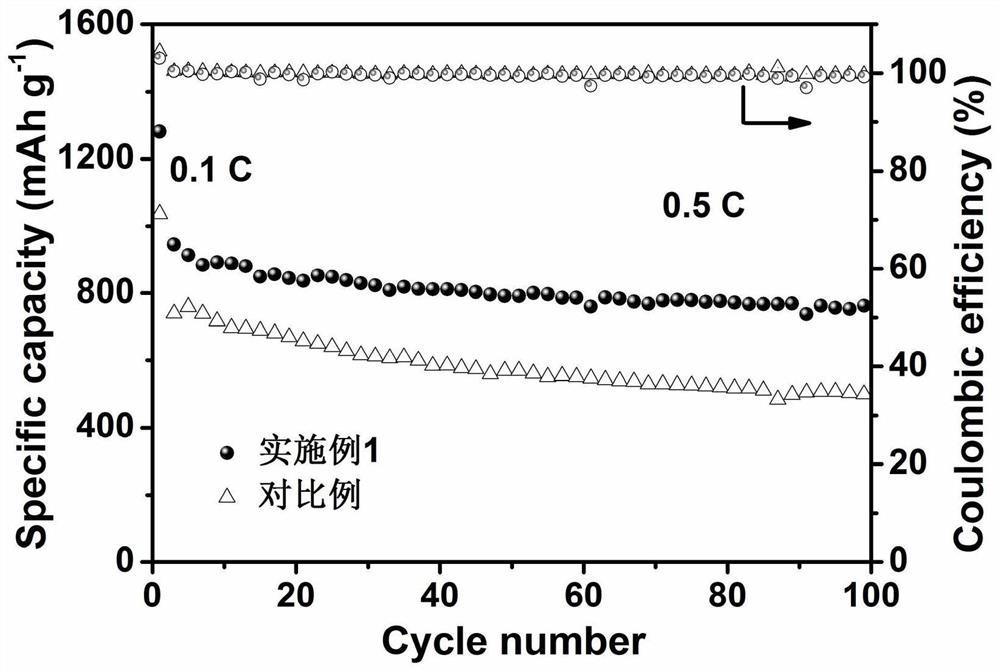

[0056] Get a three-necked flask and fill 6.3g amino-terminated polysiloxane (molecular weight M w =700-900, n=6~9, the structure is as follows: ), and 60ml dichloromethane solvent. Then add 0.25 g of 4,4'-diaminodiphenyl disulfide (p / q value depends on the ratio of amino-terminated polysiloxane to 4,4'-diaminodiphenyl disulfide, which is 9) and 3.5 ml of acid-binding agent triethylamine, placed in a temperature bath at 0°C and stirred for 30 min. Dissolve 2.04g of 2,6-pyridinedicarboxylic acid chloride in 10ml of dichloromethane, put it in a constant-pressure dropping funnel, and slowly drop it into the above-mentioned three-neck flask under stirring at a temperature of 0°C. Continue to stir for 10h until the reaction is complete. Then the solution was concentrated by rotary evaporation, poured into a polytetrafluoroethylene mold, and dried in an oven at 80° C. for 10 hours to obtain a silicone-based adhesive with self-healing properties. The binder can be applied in lith...

Embodiment 2

[0066] Polysiloxane binder is identical with embodiment 1

[0067]Preparation of self-healing binder lithium battery positive electrode: mix high-purity sulfur and carbon nanotubes at a mass ratio of 3:2, place them in a reactor at 150°C for 16 hours to obtain active materials, and mix 80 parts of active materials and 10 parts of conductive Disperse acetylene black and 10 parts of polysiloxane-based binder in N-methylpyrrolidone solvent, stir and ultrasonically mix to obtain electrode slurry, and coat the slurry on carbon-coated aluminum foil and dry it in a vacuum oven at 55°C for 12 hours , to obtain the positive electrode material.

[0068] To prepare the positive electrode of traditional binder lithium battery: mix high-purity sulfur and carbon nanotubes at a mass ratio of 3:2, place them in a reaction kettle at 150°C for 16 hours to obtain an active material, and mix 80 parts of active material and 10 parts of conductive agent Acetylene black and 10 parts of PVDF binder ...

Embodiment 3

[0071] Polysiloxane binder is identical with embodiment 1

[0072] Preparation of self-healing binder lithium battery positive electrode: mix high-purity sulfur and superconducting carbon black at a mass ratio of 3:2, place in a reactor at 150°C for 16 hours to obtain an active material, mix 80 parts of active material, 10 parts Conductive agent acetylene black and 10 parts of polysiloxane-based binder are dispersed in N-methylpyrrolidone solvent, stirred and ultrasonically mixed to obtain electrode slurry, and the slurry is coated on carbon-coated aluminum foil and dried in a vacuum oven at 55 °C 12h, the positive electrode material was obtained.

[0073] Preparation of positive electrode of traditional binder lithium battery: mix high-purity sulfur and superconducting carbon black at a mass ratio of 3:2, place in a reaction kettle at 150°C for 16 hours to obtain an active material, mix 80 parts of active material, 10 parts of conductive Acetylene black and 10 parts of PVDF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com