Efficient ultra-precise polishing method based on shear expansion effect

An expansion effect, ultra-precision technology, applied in the field of ultra-precision polishing, to achieve the effect of large contact area, improved force uniformity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

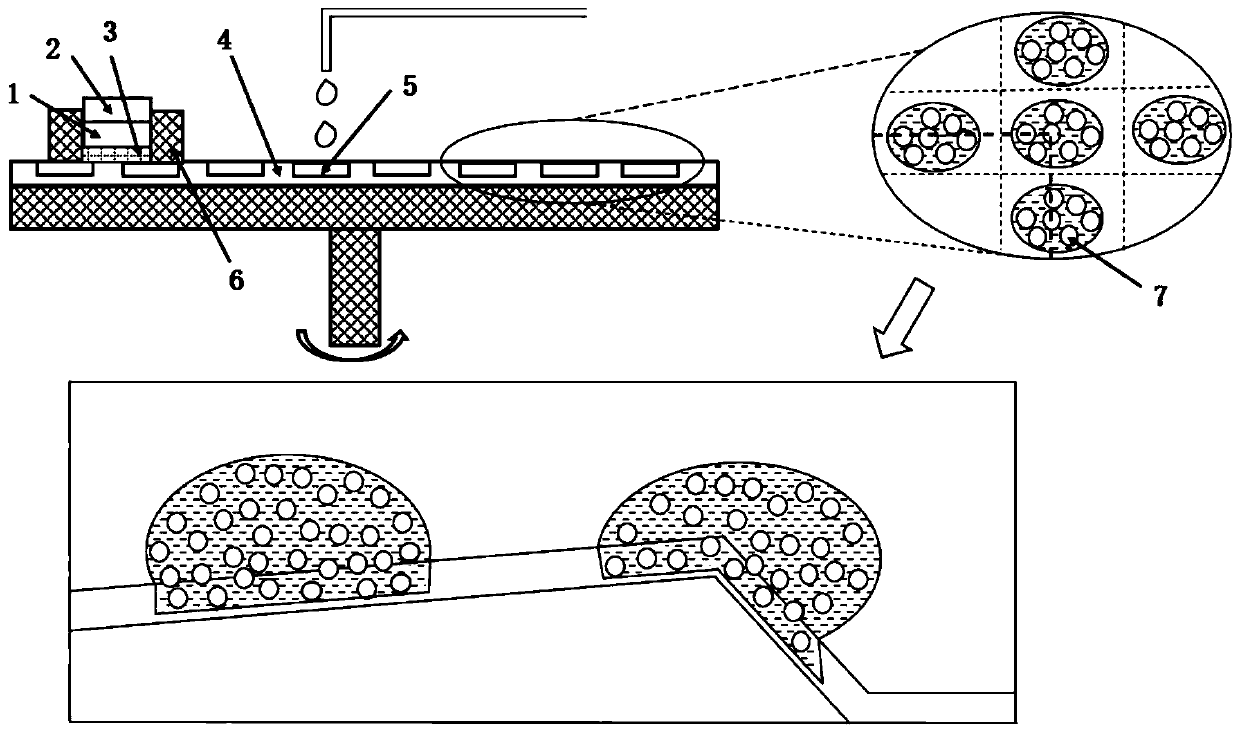

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

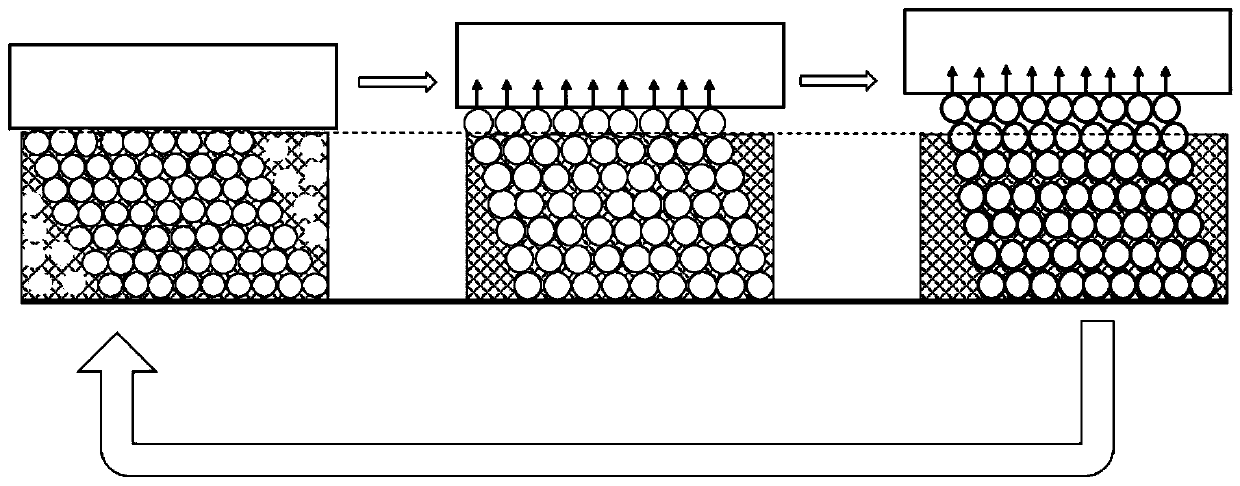

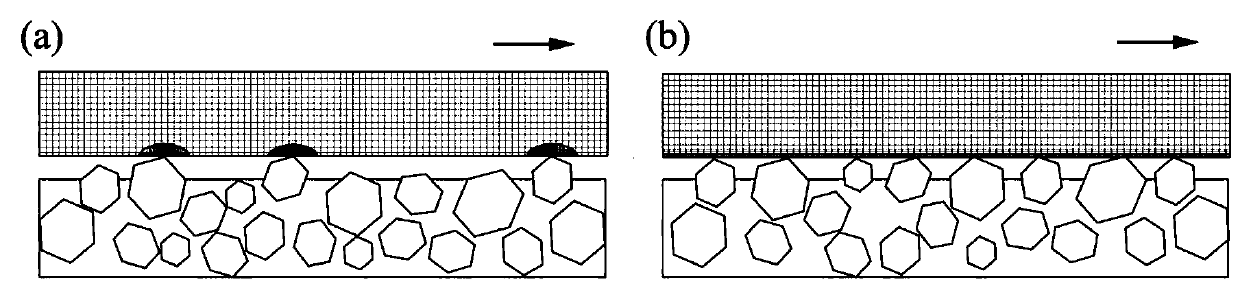

[0028] refer to Figure 1 ~ Figure 3 , a high-efficiency ultra-precision polishing method based on the shear expansion effect, using a viscoelastic material with non-Newtonian fluid properties as the rubber base, and adding abrasive particles, dispersants and activators to prepare a flexible fixed abrasive; wherein, the viscoelastic Gum base accounts for 50% to 85% of the mass fraction of the abrasive, abrasive grains account for 10% to 45% of the mass fraction of the abrasive, the particle size of the abrasive grains ranges from 0.05 to 50 μm, and the dispersant accounts for 1 to 5% of the mass fraction of the abrasive. %, the active agent accounts for 1 to 5% of the mass fraction of the abrasive;

[0029] In the present embodiment, following formula can be adopted:

[0030] 50% viscoelastic base, 40% abrasive particles, 5% dispersant and 5% activator;

[0031] Or:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com