Supporting method for underground soft rock roadway of coal mine

A roadway support and soft rock technology, applied in tunnels, shaft equipment, shaft linings, etc., can solve problems such as high cost, unreasonable input-output ratio, and inability to meet rapid construction, and achieve improved control and enhanced contact Effects of area and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing a kind of concrete implementation of soft rock roadway supporting method of coal mine underground of the present invention is described in detail, this embodiment is only used to illustrate the present invention and is not intended to limit the scope of the present invention, those skilled in the art understand each aspect of the present invention The modifications of all equivalent forms all fall within the scope defined by the appended claims of the present application.

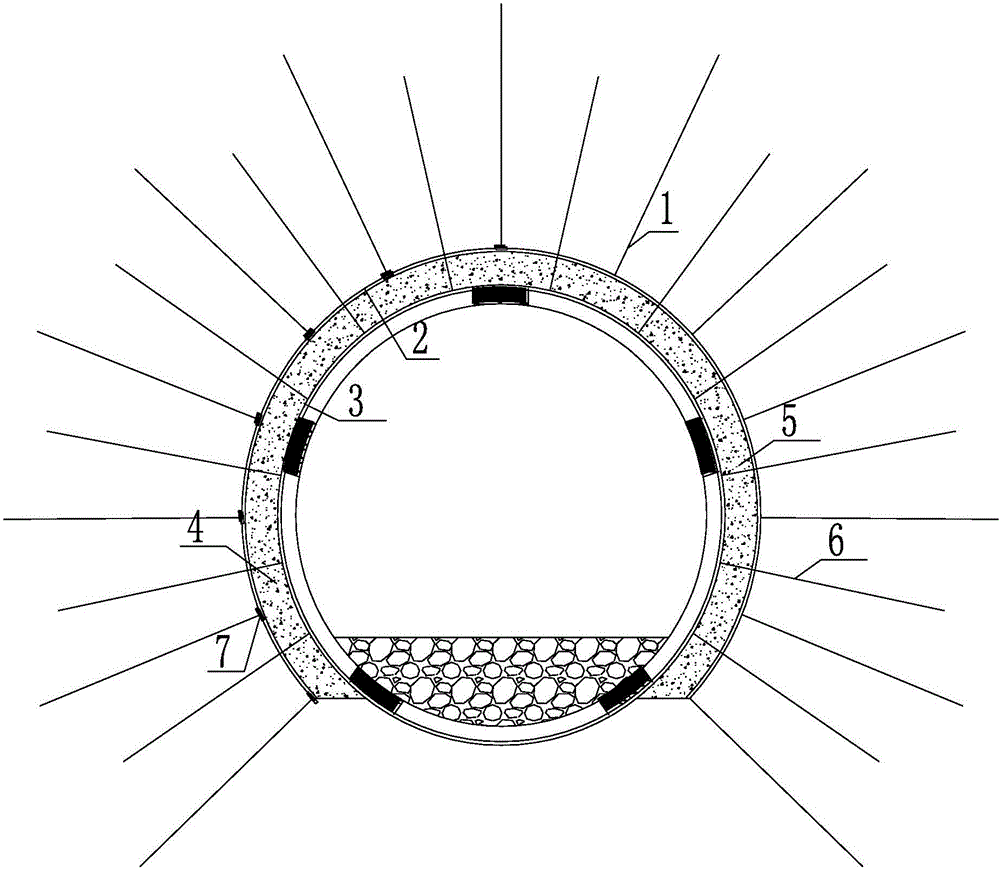

[0020] Such as figure 1 , a soft rock roadway support method in a coal mine, comprising the following steps: (1) anchor net support: after driving or brushing and expanding the roadway, the anchor net support is first used, and the bolt adopts a specification of φ20mm×2200mm or φ20mm×2400mm, The material is left-handed and non-longitudinal ribs and other strong threaded steel bolts. The bolt supporting plate is made of Q235 steel with a specification of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com