Cable material for self-repairing electromagnetic shielding cable and preparation method of cable material

An electromagnetic shielding and self-repairing technology, applied to rubber insulators, organic insulators, etc., to achieve the effect of strengthening the shielding effect, facilitating large-scale application, and having a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

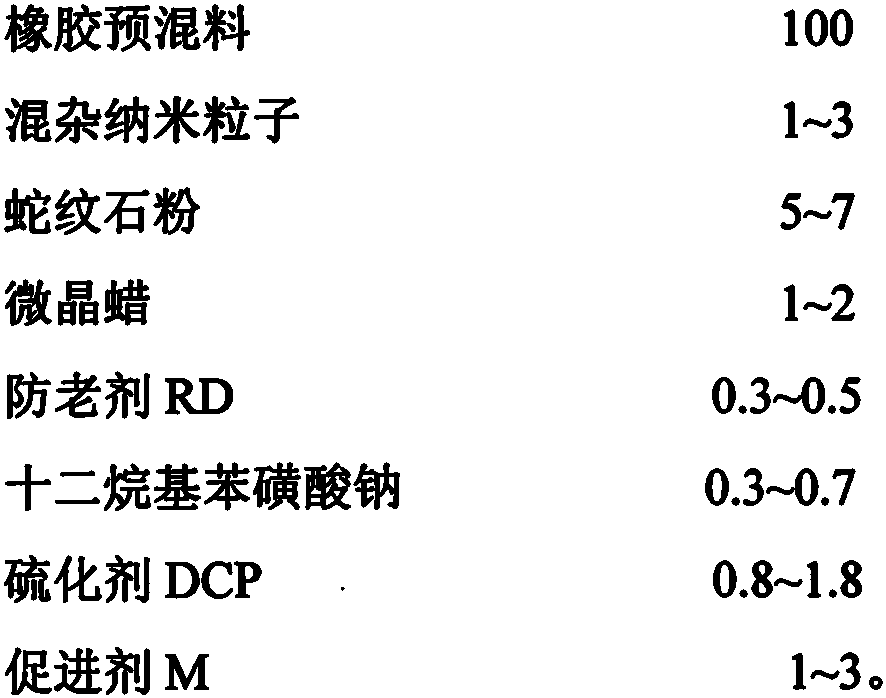

[0028] A cable material for self-repairing electromagnetic shielding cables consists of the following components in parts by weight:

[0029]

[0030] A preparation method of a cable material for a self-repairing electromagnetic shielding cable, comprising the following steps:

[0031] (1) Weigh graphene powder, formaldehyde and sodium hydroxide in a weight ratio of 1:40:2, mix them uniformly, heat up to 75°C, keep warm for 75min, filter, and wash and filter the solid product with tap water until the filtrate becomes neutral. properties, and then the solid product obtained by filtration was dried at 105° C. for 30 h to obtain a pretreated graphene powder; the average particle size (D50) of the graphene powder was 5 μm;

[0032] (2) Weigh water, pretreated graphene powder, maleic anhydride, and ammonium cerium nitrate in a weight ratio of 100:2:40:1.2, add ceric ammonium nitrate to water and stir to dissolve, then pretreat graphene Add the powder and maleic anhydride, heat ...

Embodiment 2

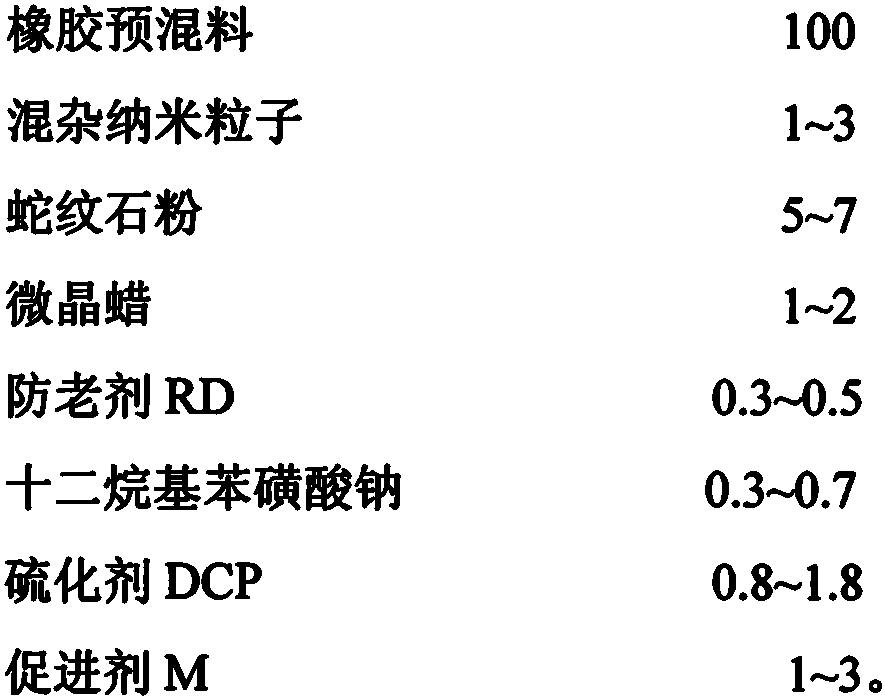

[0039] A cable material for self-repairing electromagnetic shielding cables consists of the following components in parts by weight:

[0040]

[0041] A preparation method of a cable material for a self-repairing electromagnetic shielding cable, comprising the following steps:

[0042] (1) Weigh graphene powder, formaldehyde and sodium hydroxide in a weight ratio of 1:30:1, mix them uniformly, heat up to 70°C, keep warm for 60min, filter, and wash and filter the solid product with tap water until the filtrate becomes neutral. properties, and then the solid product obtained by filtration was dried at 100° C. for 24 hours to obtain a pretreated graphene powder; the average particle size (D50) of the graphene powder was 3 μm;

[0043] (2) Weigh water, pretreated graphene powder, maleic anhydride, and ammonium cerium nitrate in a weight ratio of 100:1:30:0.8, add ceric ammonium nitrate to the water and stir to dissolve, then place the pretreated graphene Add the powder and malei...

Embodiment 3

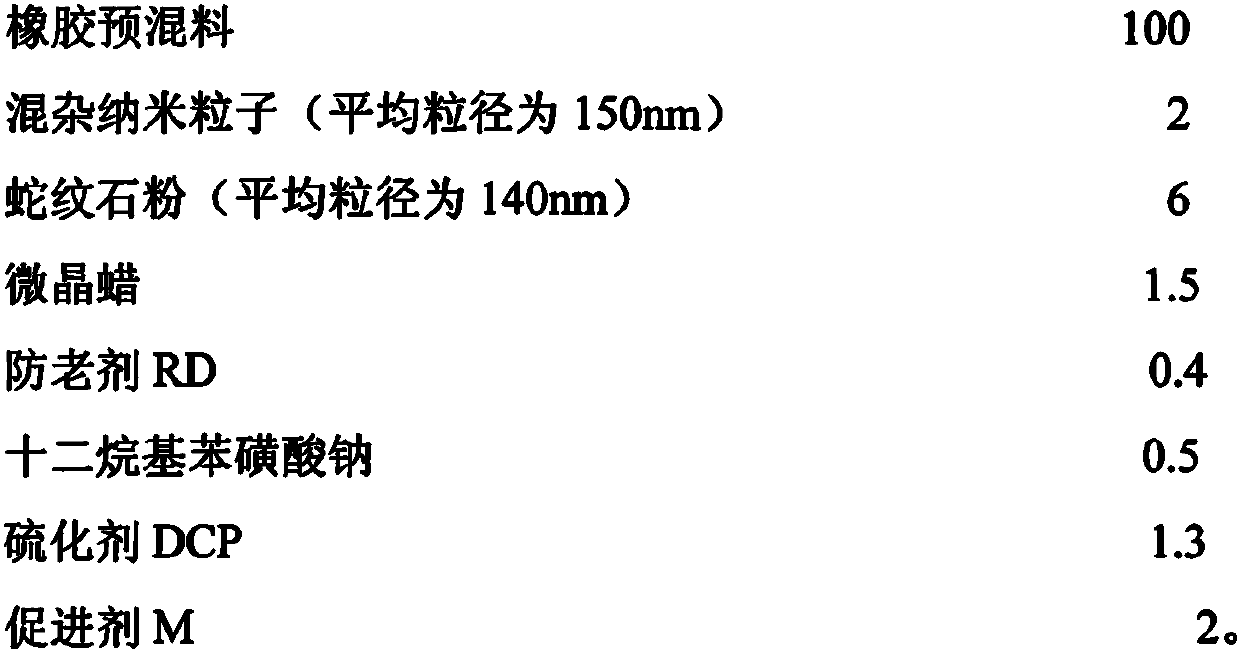

[0050] A cable material for self-repairing electromagnetic shielding cables consists of the following components in parts by weight:

[0051]

[0052] A preparation method of a cable material for a self-repairing electromagnetic shielding cable, comprising the following steps:

[0053] (1) Weigh graphene powder, formaldehyde and sodium hydroxide in a weight ratio of 1:50:3, mix them uniformly, heat up to 80°C, keep warm for 90min, filter, and wash and filter the solid product with tap water until the filtrate becomes neutral. properties, and then the solid product obtained by filtration was dried at 110° C. for 36 hours to obtain a pretreated graphene powder; the average particle size (D50) of the graphene powder was 7 μm;

[0054] (2) Weigh water, pretreated graphene powder, maleic anhydride and ammonium cerium nitrate respectively by weight ratio 100:3:50:1.6, after adding ammonium cerium nitrate to water and stirring and dissolving, pretreated graphene Add the powder an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com