A kind of cable material for self-repairing electromagnetic shielding cable and preparation method thereof

A technology of electromagnetic shielding and cable materials, applied in the field of functional materials, to achieve the effects of wide sources, enhanced shielding effect, and convenient large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

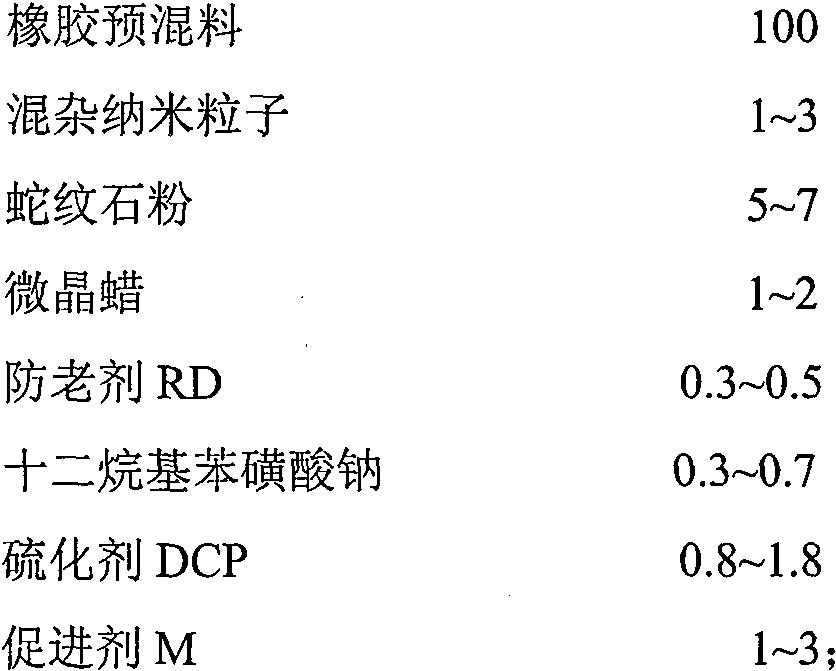

[0028] A cable material for a self-healing electromagnetic shielding cable is composed of the following components by weight:

[0029]

[0030] A preparation method of a cable material for a self-repairing electromagnetic shielding cable, comprising the following steps:

[0031] (1) take by weighing graphene powder, formaldehyde and sodium hydroxide respectively by weight ratio 1: 40: 2, after mixing, be warming up to 75 ℃, be incubated 75min, filter, adopt the solid product that tap water washing filter obtains to filtrate in Then, the solid product obtained by filtration was dried at 105 ° C for 30 h to obtain pretreated graphene powder; the average particle size (D50) of the graphene powder was 5 μm;

[0032] (2) weigh water, pretreated graphene powder, maleic anhydride and ceric ammonium nitrate respectively by weight ratio 100: 2: 40: 1.2, after adding ceric ammonium nitrate into water and stirring and dissolving, pretreated graphene The powder and maleic anhydride we...

Embodiment 2

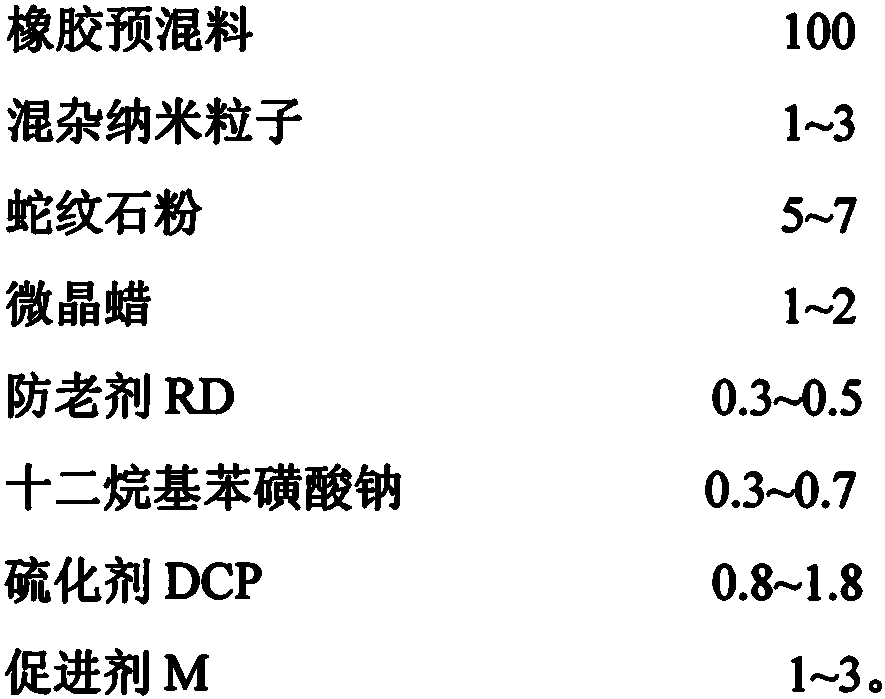

[0039] A cable material for a self-healing electromagnetic shielding cable is composed of the following components by weight:

[0040]

[0041] A preparation method of a cable material for a self-repairing electromagnetic shielding cable, comprising the following steps:

[0042] (1) take by weighing graphene powder, formaldehyde and sodium hydroxide respectively by weight ratio 1: 30: 1, after mixing, be warming up to 70 ℃, be incubated 60min, filter, adopt the solid product that tap water washing filter obtains to filtrate in Then, the solid product obtained by filtration was dried at 100 ° C for 24 hours to obtain pretreated graphene powder; the average particle size (D50) of the graphene powder was 3 μm;

[0043] (2) weigh water, pretreated graphene powder, maleic anhydride and ceric ammonium nitrate respectively by weight ratio 100: 1: 30: 0.8, after adding ceric ammonium nitrate into water and stirring and dissolving, pretreated graphene The powder and maleic anhydride ...

Embodiment 3

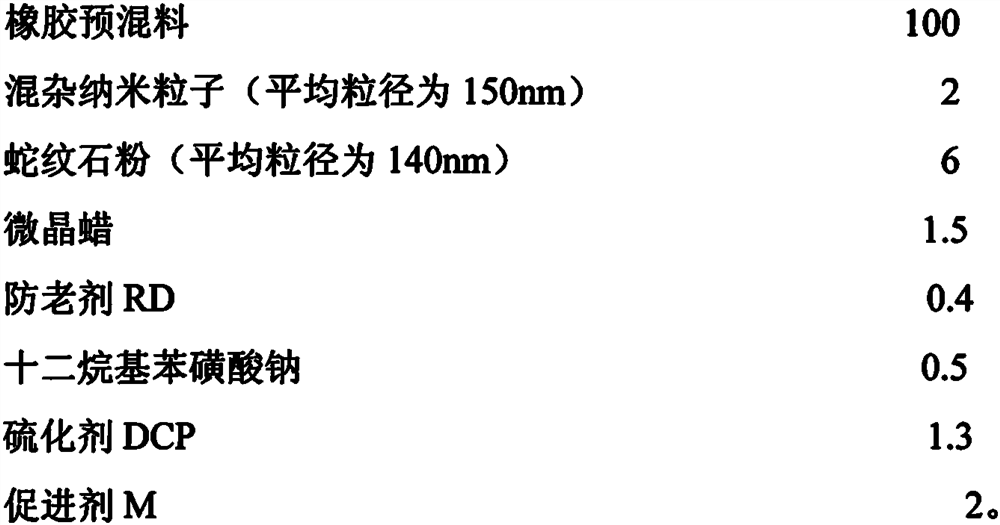

[0050] A cable material for a self-healing electromagnetic shielding cable is composed of the following components by weight:

[0051]

[0052] A preparation method of a cable material for a self-repairing electromagnetic shielding cable, comprising the following steps:

[0053] (1) take by weighing graphene powder, formaldehyde and sodium hydroxide respectively by weight ratio 1: 50: 3, after mixing, be warming up to 80 ℃, be incubated 90min, filter, adopt the solid product that tap water washing filter obtains to filtrate in Then, the solid product obtained by filtration was dried at 110 ° C for 36 hours to obtain pretreated graphene powder; the average particle size (D50) of the graphene powder was 7 μm;

[0054] (2) weigh water, pretreated graphene powder, maleic anhydride and ceric ammonium nitrate respectively by weight ratio 100:3:50:1.6, after adding ceric ammonium nitrate to water and stirring and dissolving, pretreated graphene The powder and maleic anhydride wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com