Graphene/white carbon black nanometer composite material and preparation method thereof

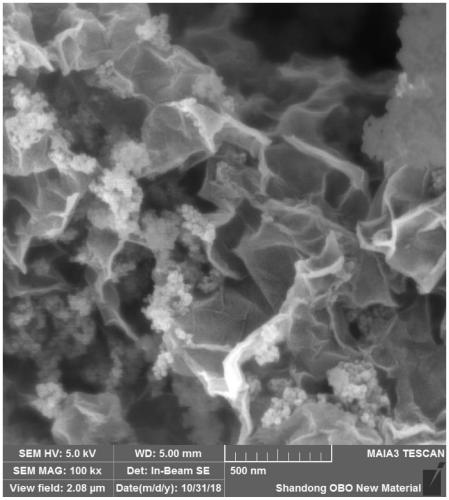

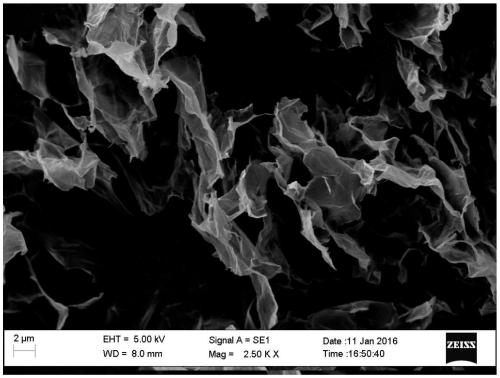

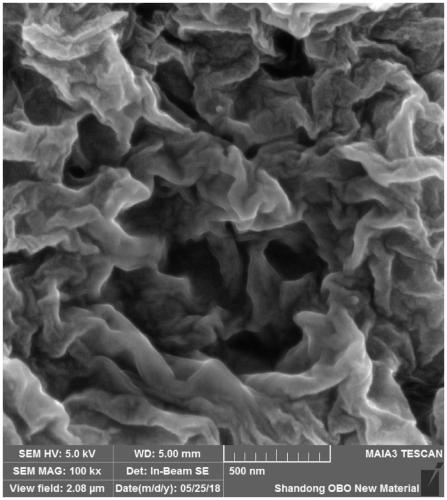

A technology of graphene-based materials and composite materials, which is applied in the field of graphene composite materials, can solve the problems of graphene oxide sheets, such as curling and folding, poor dispersion, and uneven compounding, so as to suppress self-agglomeration effects, enhance dispersion, and improve The effect of homogeneity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] The present invention also provides a kind of preparation method of graphene / white carbon black composite material, comprises the following steps:

[0081] 1) mixing the graphene oxide aqueous dispersion with a silane coupling agent, and performing a grafting reaction to obtain a reaction system;

[0082] 2) adding white carbon black to the reaction system obtained in the above steps and mixing again, and performing grafting reaction again to obtain a graphene / white carbon black composite material.

[0083] The present invention is to the selection, composition and structure of the material in the above-mentioned preparation method, and corresponding optimal principle, and the selection, composition and structure of the material in the aforementioned graphene / silica composite material, and corresponding optimal principle all preferably can Correspondingly, details are not repeated here.

[0084] In the present invention, the graphene oxide water dispersion liquid and t...

Embodiment 1

[0128] 1) Weigh 55g of graphene oxide dispersion with a concentration of 0.181%, add 228g of high-purity water, add acids such as glacial acetic acid or hydrochloric acid, adjust the pH to 3.5-4.5, and disperse with ultrasonic stirring for 1 hour.

[0129] 2) Weigh 2g of silane coupling agent Si69 and dissolve it in 50g of absolute ethanol; add the Si69 / ethanol dispersion liquid to the graphene oxide dispersion liquid dropwise, and disperse with ultrasonic stirring for 1h;

[0130] 3) Put the silane coupling agent / graphene oxide dispersion in an oil bath, raise the temperature to 70°C, and pre-react for 2 hours;

[0131] 4) Weigh 20g of white carbon black, add 200g of pure water, and ultrasonically stir and disperse for 1h to obtain a nanoscale aqueous dispersion of white carbon black;

[0132] 5) adding the silica aqueous dispersion to the pretreated silane coupling agent / graphene oxide dispersion obtained in step 3), and ultrasonically stirring and dispersing for 1 h;

[01...

Embodiment 2

[0143] 1) Weigh 55g of graphene oxide dispersion with a concentration of 0.181%, add 228g of high-purity water, add acids such as glacial acetic acid or hydrochloric acid, adjust the pH to 3.5-4.5, and disperse with ultrasonic stirring for 1 hour.

[0144] 2) Weigh 2g of silane coupling agent Si747 and dissolve it in 50g of absolute ethanol; add the Si747 / ethanol dispersion liquid to the graphene oxide dispersion liquid dropwise, and disperse with ultrasonic stirring for 1h;

[0145] 3) Put the silane coupling agent / graphene oxide dispersion in an oil bath, raise the temperature to 70°C, and pre-react for 2 hours;

[0146] 4) Weigh 20g of white carbon black, add 200g of pure water, and ultrasonically stir and disperse for 1h to obtain a nanoscale aqueous dispersion of white carbon black;

[0147] 5) adding the silica aqueous dispersion to the pretreated silane coupling agent / graphene oxide dispersion obtained in step 3), and ultrasonically stirring and dispersing for 1 h;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com