Plastic film blowing system with reheating function

A membrane system and plastic technology, used in household appliances, other household appliances, flat products, etc., can solve the problems of low energy utilization rate, environmental pollution, physical injury of operators, etc., to improve energy utilization rate and compact structure. , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

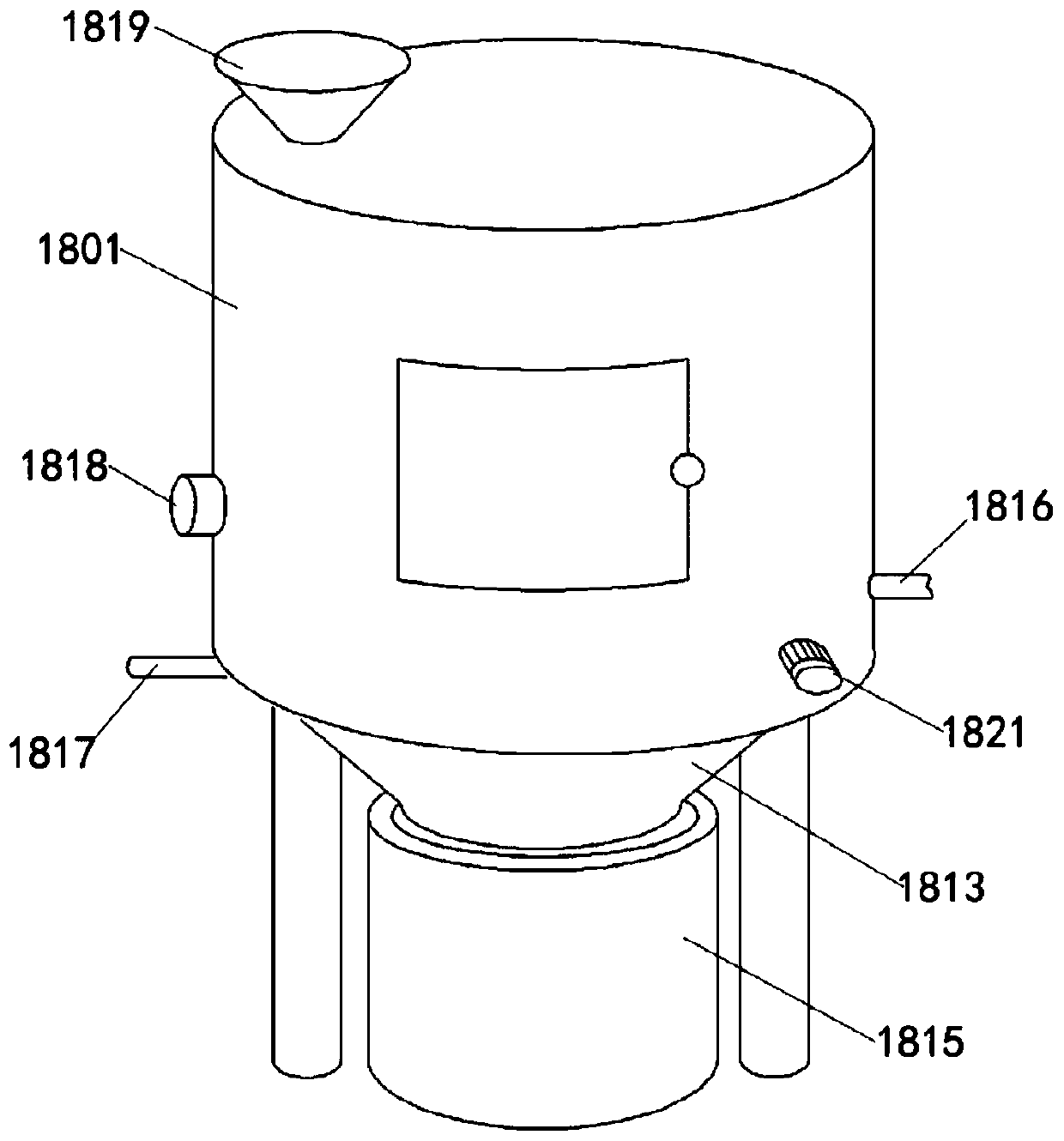

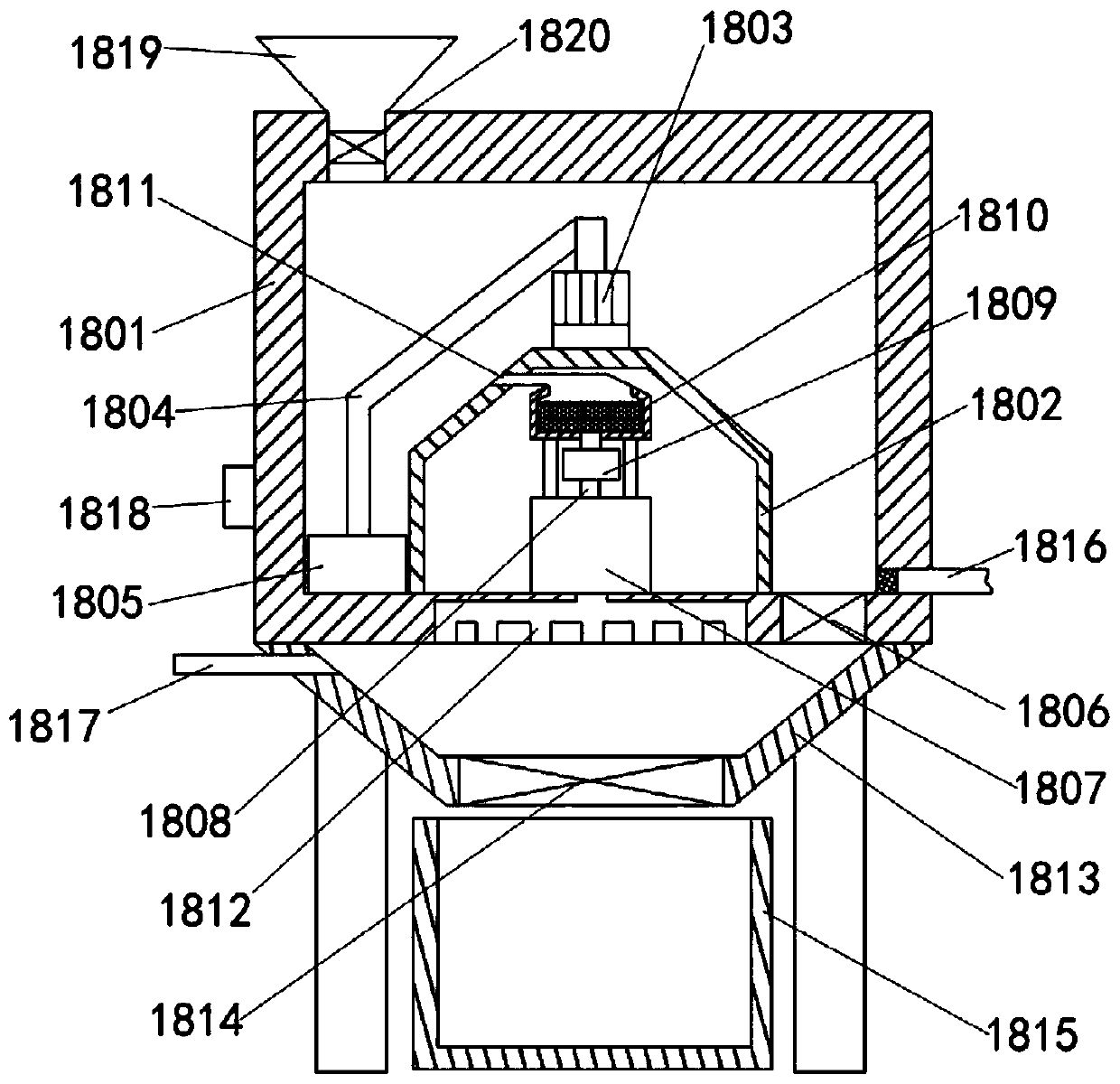

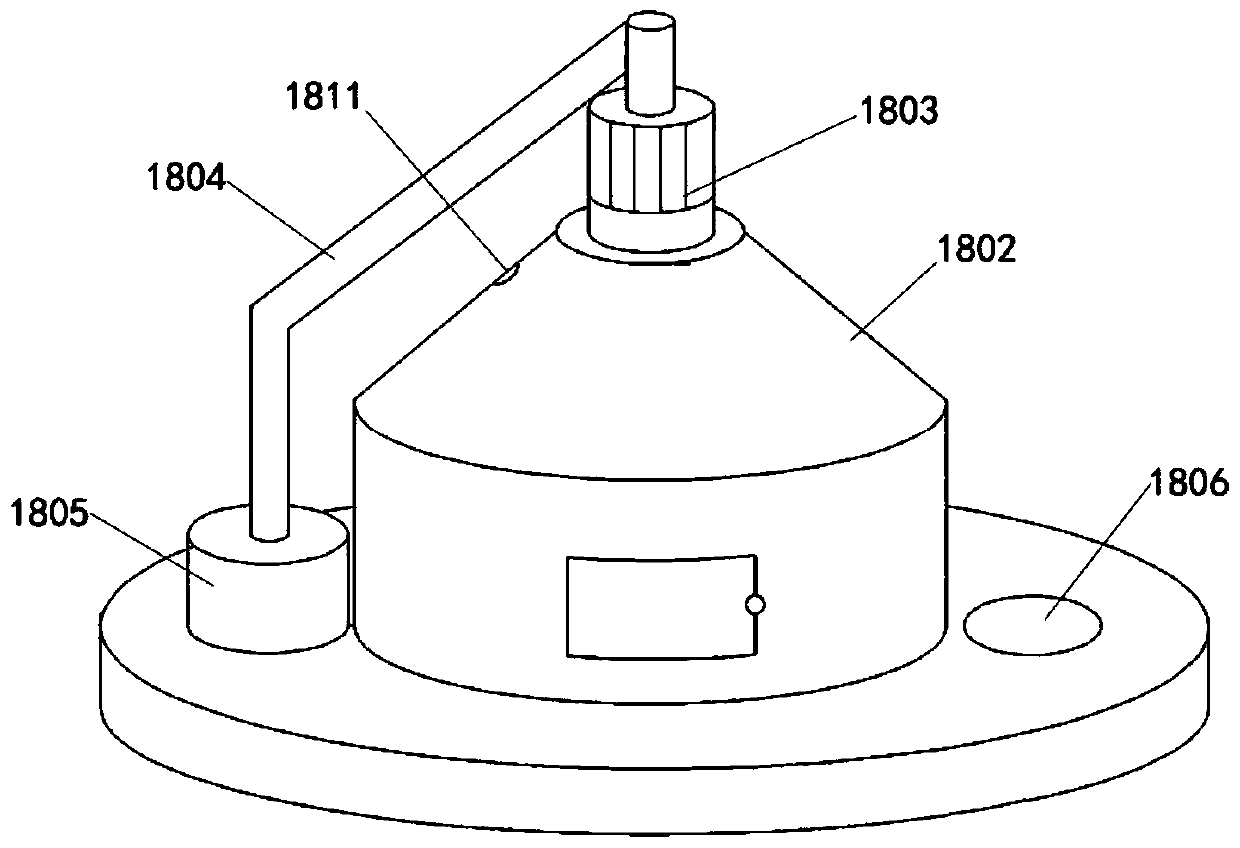

[0039] Example: such as Figure 1-14A plastic film blowing system with a reheating function is shown, including a raw material drying device and a film blowing device, and the plastic raw materials dried by the raw material drying device are manually fed into the storage hopper 7 of the film blowing device; the raw material drying device includes drying Housing 1801, the bottom wall of the drying housing 1801 is fixed with a reheat cylinder 1802, the upper end of the reheat cylinder 1802 is fixed with a stirring motor 1803, the output shaft of the stirring motor 1803 is fixed with a stirring block 1805 through a folding rod 1804, and the drying An electric blanking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com