Method for producing aerated concrete blocks by lime wet pulping

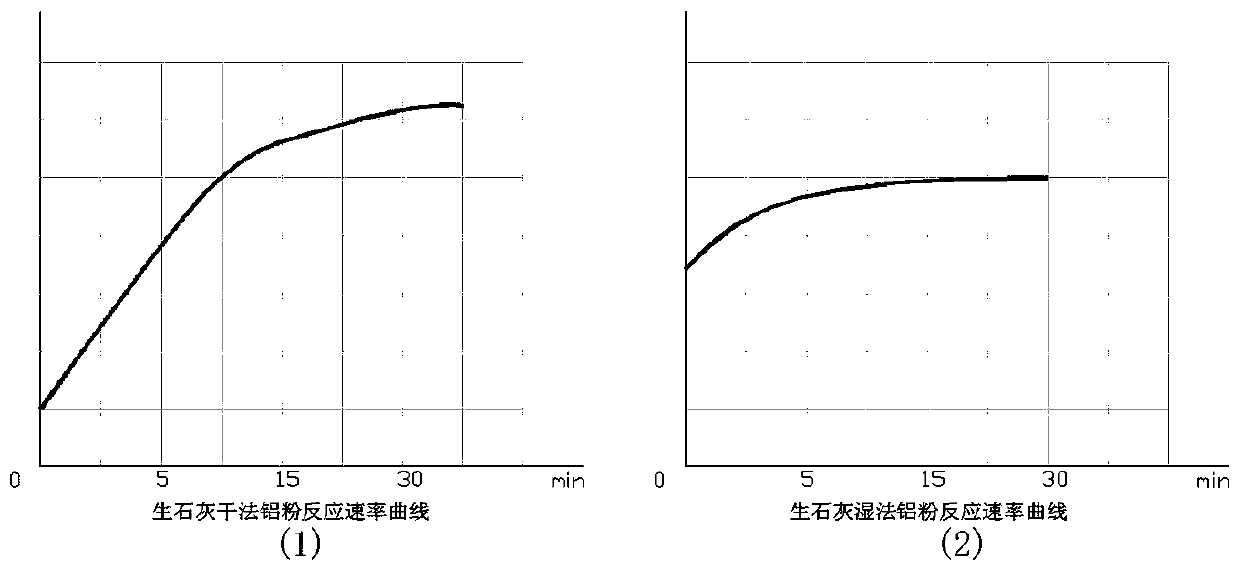

An air-entrained concrete and wet process technology, applied in chemical instruments and methods, manufacturing tools, ceramic products, etc., can solve problems such as high environmental protection requirements, reduction of tobomullite structure formation rate, active calcium oxide damage, etc. Achieve the effect of improving pouring stability, shortening thickening time and increasing thickening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

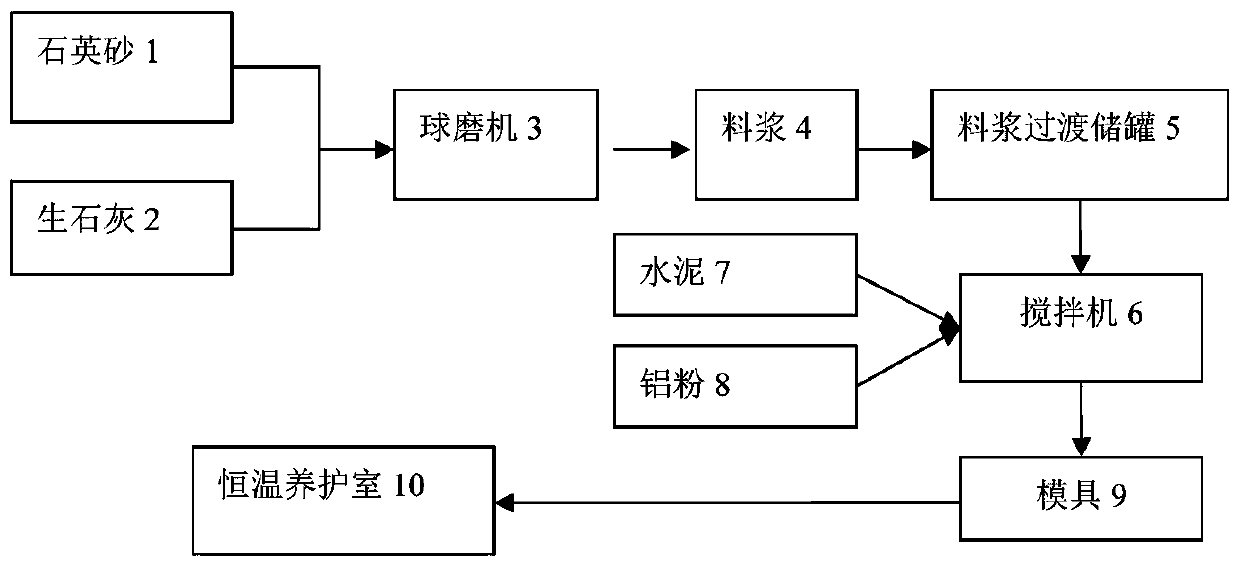

[0032] A method for lime wet pulping to produce aerated concrete blocks. Quartz sand and quicklime are added to a ball mill and mixed with water for wet grinding (mass ratio, sand:lime:water=5:1.2:3.8) to make slurry, and quicklime is used to It is water-soluble and exothermic when it encounters water, making a uniform and stable thermal slurry. The refining process is controlled by four indicators of available calcium in the slurry (mass fraction = 9%), fineness (0.088mm standard sieve: 26%), temperature (normally 39°C), and concentration (63%).

[0033]When producing and pouring, pump the ground slurry into the batching mixer according to the batching requirements, then add 1.2 parts of ordinary Portland cement, and stir for 3.5 minutes. After stirring evenly, add 0.003 parts of aluminum powder and 0.005 parts of polycarboxylate superplasticizer part (sulfamate formaldehyde condensate), 0.006 part of bubble stabilizer (the bubble stabilizer described is oleic acid C 18:1 , ...

Embodiment 2

[0037] A method for lime wet pulping to produce aerated concrete blocks. Quartz sand and quicklime are added to a ball mill and mixed with water for wet grinding (mass ratio, sand:lime:water=5:1:4) to make slurry, and quicklime is used to It is water-soluble and exothermic when it encounters water, making a uniform and stable thermal slurry. The refining process is controlled by four indicators of available calcium in the slurry (mass fraction = 13%), fineness (0.088mm standard sieve: 28%), temperature (normally 40°C), and concentration (64%).

[0038] When producing and pouring, pump the ground slurry into the batching mixer according to the batching requirements, then add 1.0 parts of ordinary Portland cement, and stir for 3.5 minutes. After stirring evenly, add 0.002 parts of aluminum powder and 0.004 parts of polycarboxylate superplasticizer part (melamine formaldehyde condensation polymer), 0.005 part of bubble stabilizer (the bubble stabilizer described is oleic acid C ...

Embodiment 3

[0042] A method for lime wet pulping to produce aerated concrete blocks. Quartz sand and quicklime are added to a ball mill and mixed with water for wet grinding (mass ratio, sand:lime:water=5:0.8:4.2) to make slurry, and quicklime is used The properties of hydrophilicity and water exotherm make a uniform and stable thermal slurry 4. The refining process is controlled by four indicators of available calcium in the slurry (mass fraction = 8%), fineness (0.088mm standard sieve: 30%), temperature (38°C under normal conditions), and concentration (62%).

[0043] When producing and pouring, pump the ground slurry into the batching mixer according to the batching requirements, then add 1.0 parts of ordinary Portland cement, and stir for 3.5 minutes. After stirring evenly, add 0.003 parts of aluminum powder and 0.0045 parts of polycarboxylate superplasticizer part (acetone sulfonate formaldehyde condensate), 0.007 part of bubble stabilizer (the bubble stabilizer described is oleic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com