A kind of fe-v gradient material and preparation method thereof

A gradient material and gradient layer technology, applied in jewelry and other fields, can solve the problems of poor mechanical properties of materials and pores in composite layers, and achieve the effects of low cost, dense surface structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The preparation method of the Fe-V gradient material adopts the following specific process.

[0025] According to the NaCl:KCl:NaF molar ratio of 0.4:0.4:0.2, weigh it as the medium, V 2 O 3 The amount added accounts for 0.5% of the total mass of the molten salt system. The above four reagents are mixed evenly and then put into a crucible, placed in an electric furnace filled with Ar gas protection, heated to 700 ° C, and kept for 80 min. Put in V plate anode and low carbon steel sheet cathode, at 700℃, 120mA / cm 2 After electrodeposition was carried out for 60 min under the pulsed current density of 100 ℃, the cathode was taken out, boiled with boiling water to remove the molten salt attachment, and then rinsed with deionized water and alcohol in turn to obtain the Fe-V gradient material.

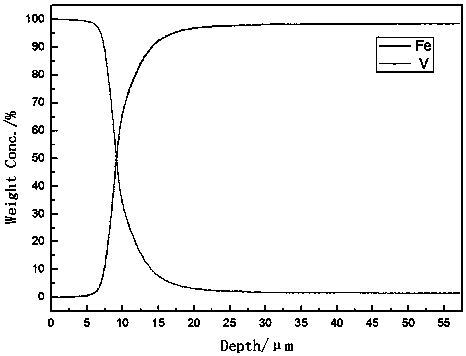

[0026] The Fe-V gradient material obtained in this example was analyzed by GDA750 glow discharge spectrometer and SEM, and the figure 1 It can be seen that the surfa...

Embodiment 2

[0027] Embodiment 2: The preparation method of the Fe-V gradient material adopts the following specific process.

[0028] According to the NaCl:KCl:NaF molar ratio of 0.35:0.35:0.3, take it as the medium, V 2 O 3 The amount added accounts for 1% of the total mass of the molten salt system. The above four reagents are mixed evenly and then put into a crucible, placed in an electric furnace filled with Ar gas protection, heated to 720 ° C, and kept for 100 min. Put V plate anode and mild steel sheet cathode at 720℃, 150mA / cm 2 After electrodeposition was carried out for 80 min under the pulsed current density of 100 °C, the cathode was taken out, boiled with boiling water to remove the molten salt attachment, and then rinsed with deionized water and alcohol in turn to obtain the Fe-V gradient material.

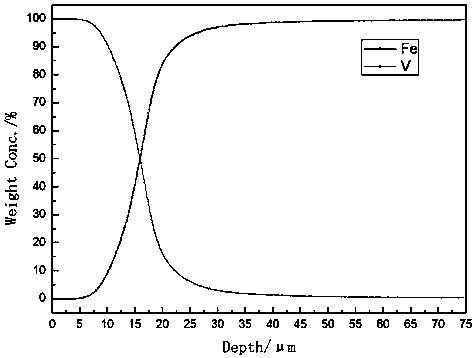

[0029] The Fe-V gradient material obtained in this example was analyzed by GDA750 glow discharge spectrometer and SEM, and the figure 2 It can be seen that the surfaces on b...

Embodiment 3

[0030] Embodiment 3: The preparation method of the Fe-V gradient material adopts the following specific process.

[0031] According to the NaCl:KCl:NaF molar ratio of 0.3:0.3:0.4, weigh it as the medium, V 2 O 3 The addition amount accounts for 1.5% of the total mass of the molten salt system. The above four reagents are mixed uniformly and then put into a crucible, and then placed in an electric furnace filled with Ar gas protection to heat up to 740 ° C, and the constant temperature time is 120 min. Put in V plate anode and mild steel sheet cathode, at 740℃, 200mA / cm 2 After electrodeposition was carried out for 100 min under the pulsed current density of 100 °C, the cathode was taken out, boiled with boiling water to remove the molten salt attachment, and then rinsed with deionized water and alcohol in turn to obtain the Fe-V gradient material.

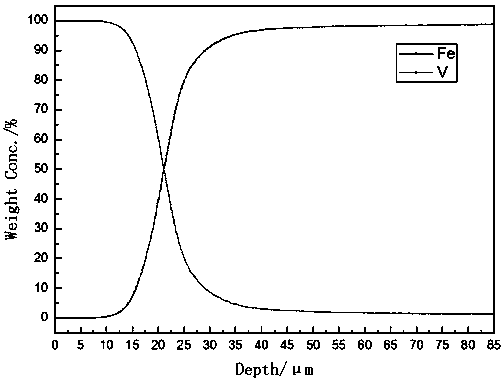

[0032] The Fe-V gradient material obtained in this example was analyzed by GDA750 glow discharge spectrometer and SEM, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com