A New Preparation Technology of Thermal Barrier Coating

A technology of thermal barrier coating and preparation process, which is used in metal material coating process, coating, melt spraying and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

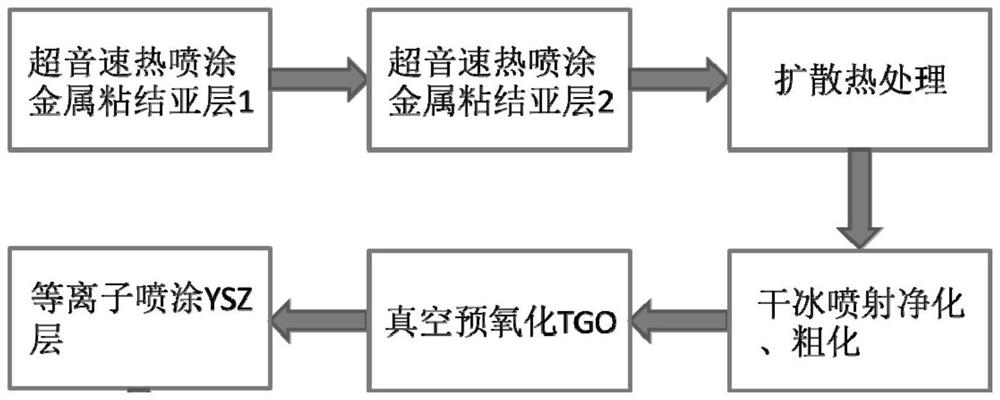

[0051] Step 1. Generate a composite metal bond primer on the surface of the substrate. Specifically include:

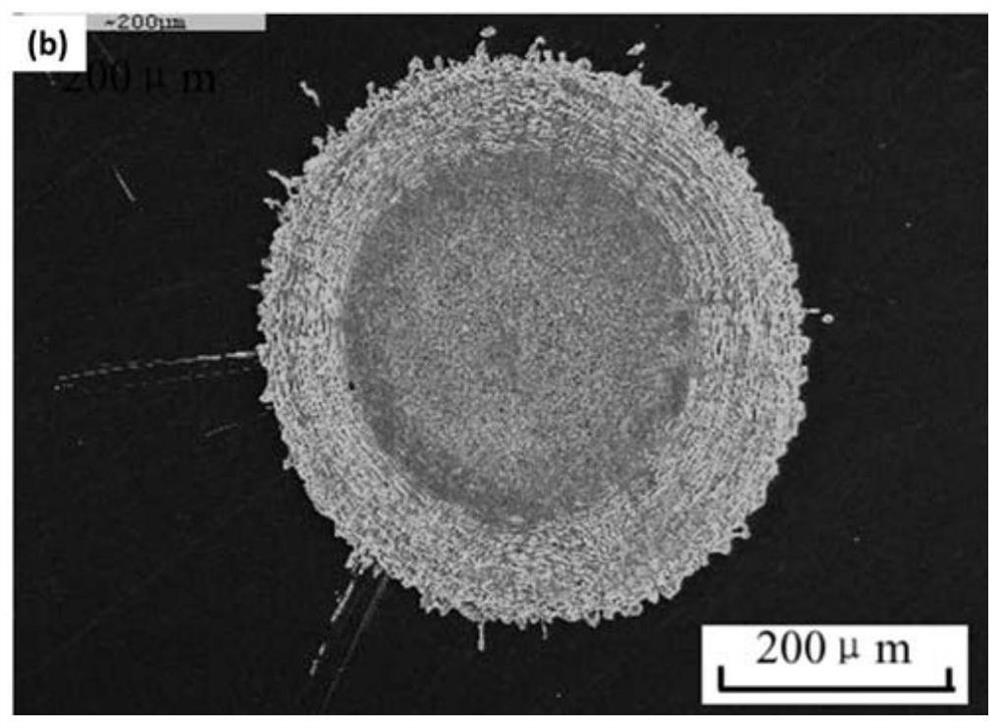

[0052] Step 11. Prepare a first metal bonding primer layer of about 50 μm on the surface of the substrate by a supersonic flame spraying process.

[0053] Step 12. Prepare a second metal bonding primer layer of about 50 μm on the surface of the substrate by a supersonic flame spraying process.

[0054] Both the first metal bond primer and the second metal bond primer were made of MCrAlY powder. The second metallic bond primer has a greater aluminum content than the first metallic bond primer.

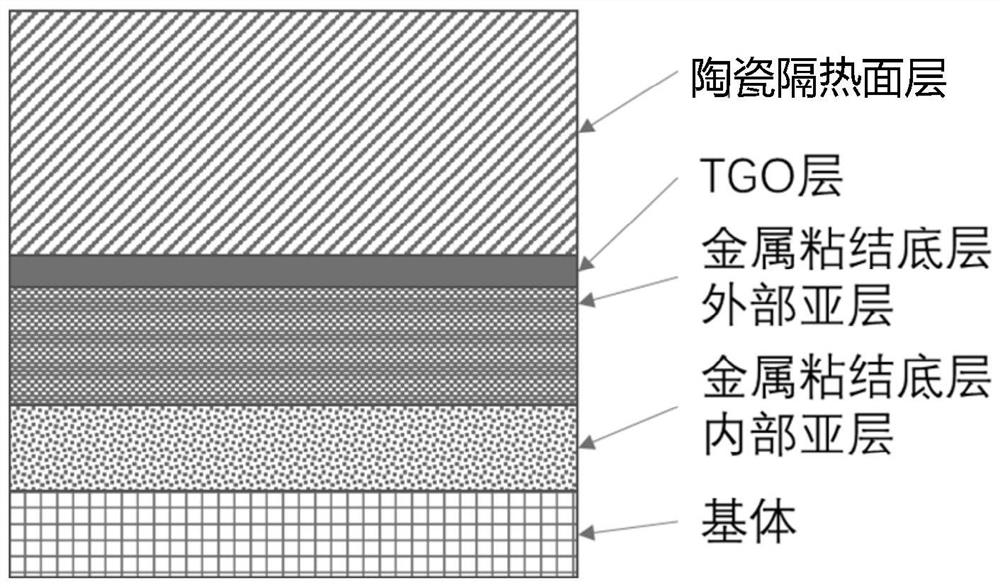

[0055] Step 13. Vacuum diffusion heat treatment. Interdiffusion occurs between the first metal bonding primer and the second metal bonding primer, forming a layer on the surface consisting of an outer sublayer that is relatively aluminum-rich and has a higher elastic modulus and an inner layer that is relatively chromium-rich and has a lower elastic modulus Composite metal ...

Embodiment 2

[0061] Step 1. Generate a composite metal bond primer on the surface of the substrate. Specifically include:

[0062] Step 11. Prepare a first metal bonding primer layer with a thickness of about 100 μm on the surface of the substrate by a supersonic flame spraying process.

[0063] Step 12. Prepare a second metal bonding primer with a thickness of about 100 μm on the surface of the substrate by a supersonic flame spraying process.

[0064] Both the first metal bond primer and the second metal bond primer were made of MCrAlY powder. The second metallic bond primer has a greater aluminum content than the first metallic bond primer.

[0065] Step 13. Vacuum diffusion heat treatment. Interdiffusion occurs between the first metal bonding primer and the second metal bonding primer, forming a layer on the surface consisting of an outer sublayer that is relatively aluminum-rich and has a higher elastic modulus and an inner layer that is relatively chromium-rich and has a lower ela...

Embodiment 3

[0071] Step 1. Generate a composite metal bond primer on the surface of the substrate. Specifically include:

[0072] Step 11. Prepare a first metal bonding primer layer with a thickness of about 150 μm on the surface of the substrate by a supersonic flame spraying process.

[0073] Step 12. Prepare a second metal bonding primer with a thickness of about 150 μm on the surface of the substrate by a supersonic flame spraying process.

[0074] Both the first metal bond primer and the second metal bond primer were made of MCrAlY powder. The second metallic bond primer has a greater aluminum content than the first metallic bond primer.

[0075] Step 13. Vacuum diffusion heat treatment. Interdiffusion occurs between the first metal bonding primer and the second metal bonding primer, forming a layer on the surface consisting of an outer sublayer that is relatively aluminum-rich and has a higher elastic modulus and an inner layer that is relatively chromium-rich and has a lower ela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| sublimation point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com