Disinfection method

A disinfection method and technology of disinfectant, applied in disinfection, sanitary equipment for toilets, water supply devices, etc., can solve the problems of insufficient disinfection, lack of disinfection needs for disinfection methods, affecting the safety of people's lives and properties, and achieves the requirements for disinfection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

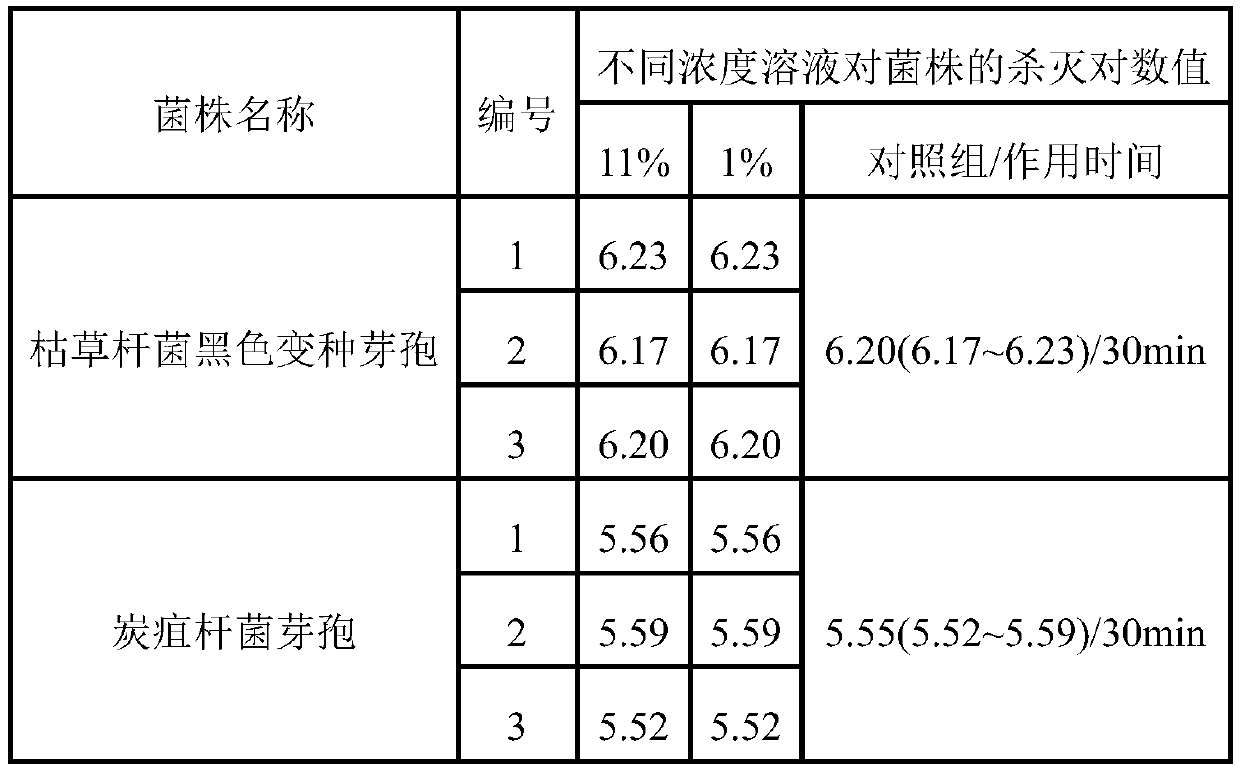

[0113] Quantitative sterilization experiment, the specific steps are as follows:

[0114] Disinfection group: suck 5mL of the disinfectant solution into a sterile test tube, pipette 20μL of the bacterial suspension into the disinfectant solution with a micropipette, and let it act for a specified time, then immediately pipette 0.5mL of the reaction solution into a test tube containing 4.5mL of neutralizer Medium; after shaking and mixing, draw 0.5mL of the final sample solution and inoculate it on a nutrient agar plate, culture it in a 37°C incubator for 48 hours, and count viable bacteria. The experiment was repeated 3 times.

[0115] Control group: draw 5mL of the diluent into a sterile test tube, pipette 20μL of the bacterial suspension into the diluent with a micropipette, let it react for a specified time, and immediately pipette 0.5mL of the reaction solution into the test tube containing 4.5mL of the diluent; After 10-fold serial dilution, select a suitable dilution su...

Embodiment 2

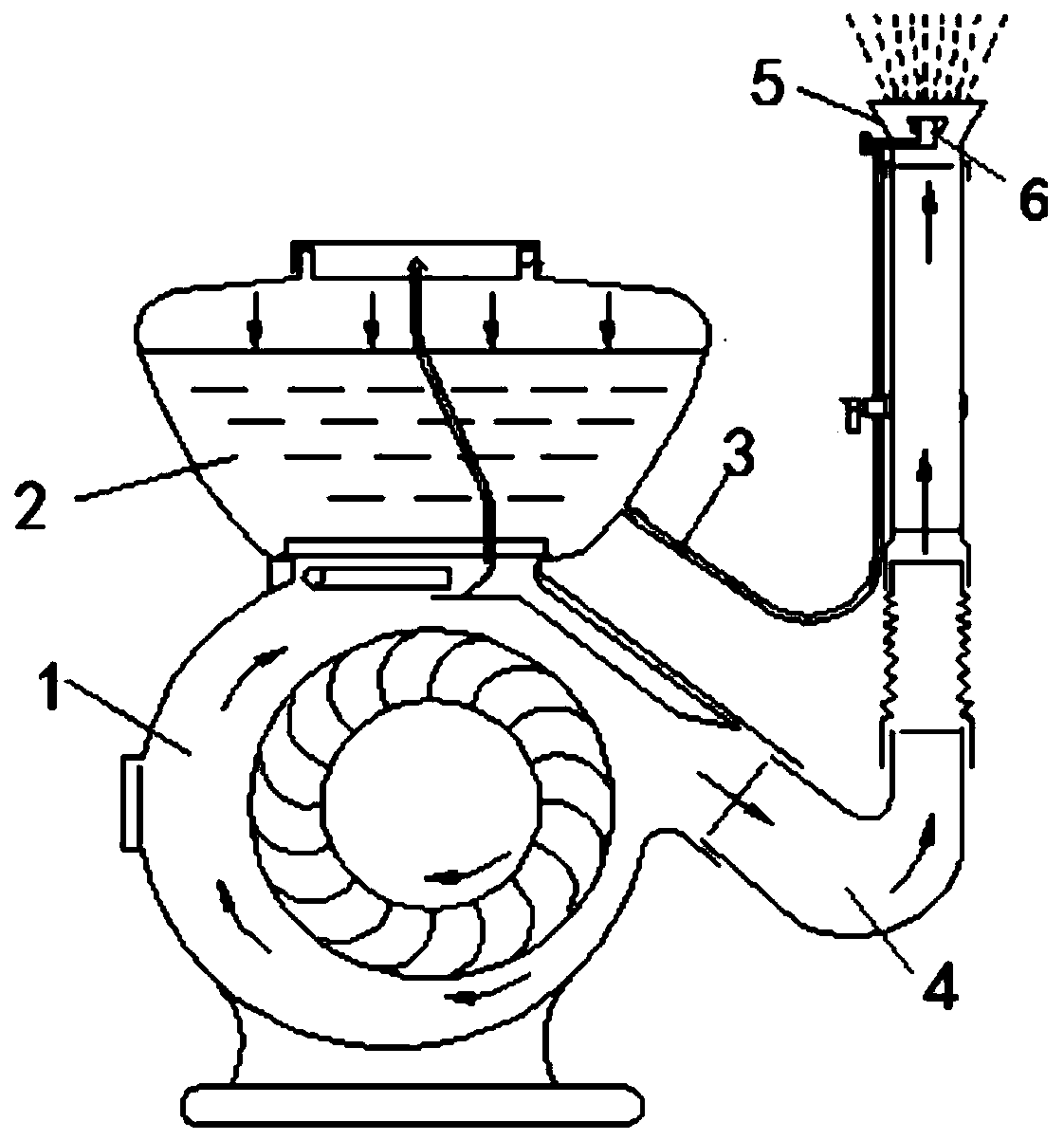

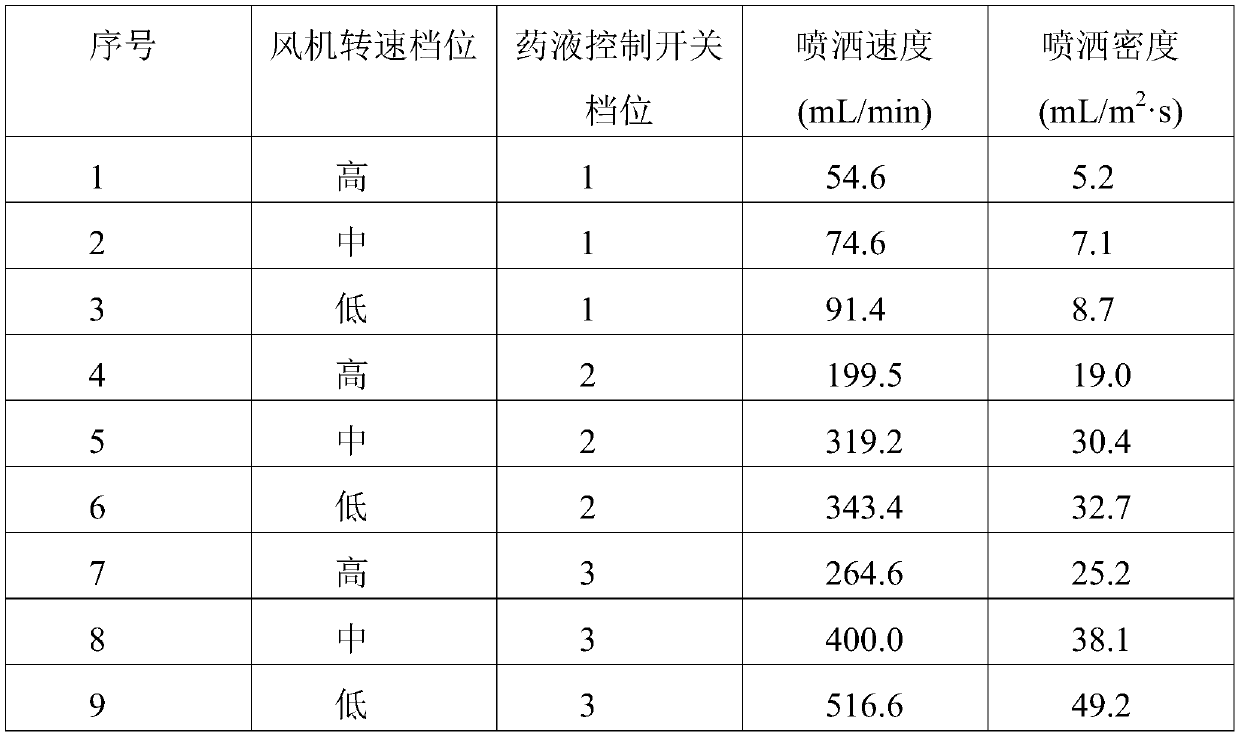

[0120] The structure of the decontaminator used in this embodiment is as attached figure 1 As shown, the fan speed of the decontaminator is divided into three gears of "high, medium and low", and the standard speed is 6800r / min; the liquid control switch is divided into three gears of "1, 2, 3" from small to large . The spraying speed and spraying density of the disinfectant are inherent parameters of the sterilizer, which are determined by the speed of the fan and the liquid output, as shown in Table 2.

[0121] Table 2

[0122]

[0123] Note: The spraying amount of disinfectant is the product of the spraying density and the spraying time.

[0124] The specific experimental steps of using the above-mentioned sterilizer to carry out the disinfection experiment are as follows:

[0125] 1) Cloth bacteria: Weigh 10g of sterile soil into a sterile petri dish (diameter 8cm); secondly, pipette 100μL of bacterial suspension with a 10-100μL micropipette, and drop it on the surface...

Embodiment 3

[0137] The decontamination device used in embodiment 3 is the same as that in embodiment 2. Using the disinfector to disinfect the surface of the equipment coating, the disinfectants used are: bleaching powder disinfectant with a mass content of calcium hypochlorite of 1%, hydrogen peroxide with a mass content of 5% Disinfectant or chlorine dioxide and chlorine dioxide disinfectant with a mass content of 20%. The specific experimental steps are as follows:

[0138] 1) Cloth bacteria: Use a 10-100μL micropipette to pipette 100μL of bacterial suspension, and apply it on the surface of the equipment coating (the area is about 30cm 2 ), the number of infection points is greater than 20.

[0139] 2) Disinfection group: basically the same as in Example 2, the difference is: open the air flow control valve to the mid-range, then open the liquid medicine flow control valve to the 2nd gear; stop spraying the disinfectant aerosol after the spraying time is 20s; The sample is placed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com