Palladium composite catalyst and its preparation method and application

A composite catalyst and catalyst technology, applied in the direction of catalytic reaction, preparation of amino compounds, chemical instruments and methods, etc., can solve the problems of reducing the quality of aromatic amine products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

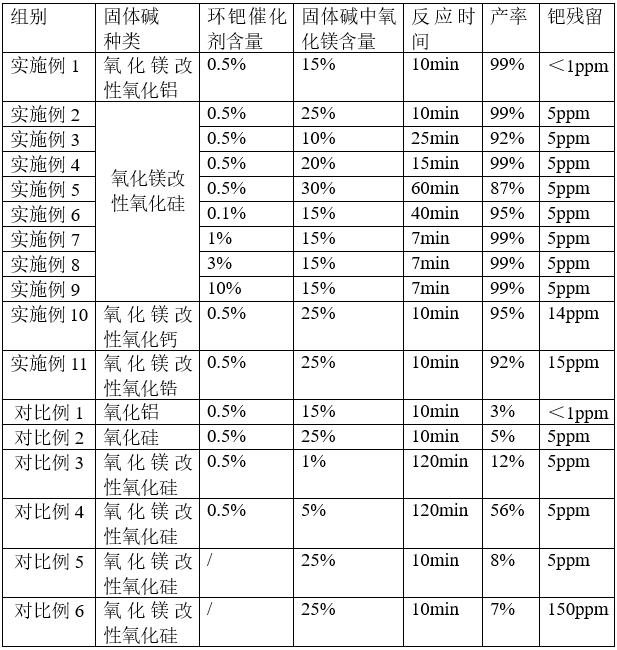

Examples

preparation example Construction

[0041] Another embodiment of the present invention provides a kind of preparation method of palladium composite catalyst, comprises the steps:

[0042] Raw materials are provided according to the content ratio of the cyclopalladium catalyst and the solid base in the palladium composite catalyst of any one of the above;

[0043] The cyclopalladium catalyst and the solid base are mixed in a solvent, and the solvent is evaporated to obtain a palladium composite catalyst.

[0044] It can be understood that the raw materials used in the above preparation method are provided according to the content ratio of the cyclopalladium catalyst and the solid base in the palladium composite catalyst.

[0045] The above preparation method mixes the cyclopalladium catalyst and the solid base in a solvent, wherein the cyclopalladium catalyst is dissolved in the solvent as a homogeneous catalyst, and with the evaporation of the solvent, the homogeneous catalyst is precipitated on the surface of the...

Embodiment 1

[0071] (1) Preparation of palladium composite catalyst:

[0072] 1 gram of cyclopalladium catalyst was dissolved in 100 grams of dichloromethane, 199 grams of 15% magnesium oxide modified alumina was added and stirred for 4 hours, and the dichloromethane was evaporated to dryness at 40 degrees Celsius to obtain 200 grams of palladium composite catalyst.

[0073] (2) Catalytic reaction of palladium composite catalyst:

[0074] Add 1 gram of the palladium composite catalyst prepared above, 0.05mol of X-phos, 0.5mol of aniline and 0.5mol of chlorobenzene, dissolve in 10L of dioxane, heat up to 100°C, and react for 10 minutes; add Methanol is heated to 60 degrees Celsius, the cyclopalladium catalyst is reduced on the surface of the solid base, the solid and liquid are separated, the solid is recovered, and the diphenylamine product is obtained from the filtrate, and the reaction yield is 99%. Use HPLC to detect the diphenylamine product, and the product purity is 98%.

Embodiment 2

[0076] (1) Preparation of palladium composite catalyst:

[0077] Dissolve 1 gram of cyclopalladium catalyst in 100 grams of dichloromethane, add 199 grams of 25% magnesia-modified silicon oxide and stir for 4 hours, and evaporate the dichloromethane to dryness at 40 degrees Celsius to obtain 200 grams of palladium composite catalyst.

[0078] (2) Catalytic reaction of palladium composite catalyst:

[0079] Add 1 gram of the palladium composite catalyst prepared above, 0.05mol of X-phos, 0.5mol of aniline and 0.5mol of chlorobenzene, dissolve in 10L of dioxane, heat up to 100°C, and react for 10 minutes; add Methanol is heated to 60 degrees Celsius, the cyclopalladium catalyst is reduced on the surface of the solid base, the solid and liquid are separated, the solid is recovered, and the diphenylamine product is obtained from the filtrate, and the reaction yield is 99%. Use HPLC to detect the diphenylamine product, and the product purity is 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com