Anode material for high-capacity lithium-ion battery with micron particles based on conversion reaction and its preparation method and application

A lithium-ion battery, negative electrode material technology, applied in nanotechnology for materials and surface science, battery electrodes, negative electrodes, etc., can solve problems such as volume change, achieve high conductivity, prevent peeling and fragmentation, mechanical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

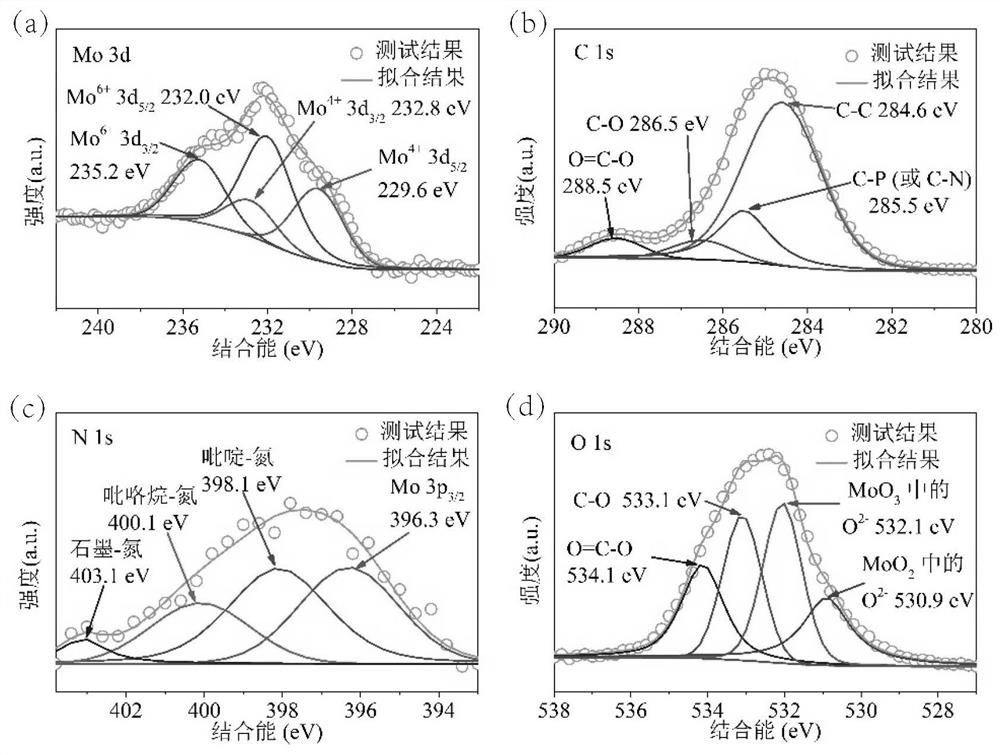

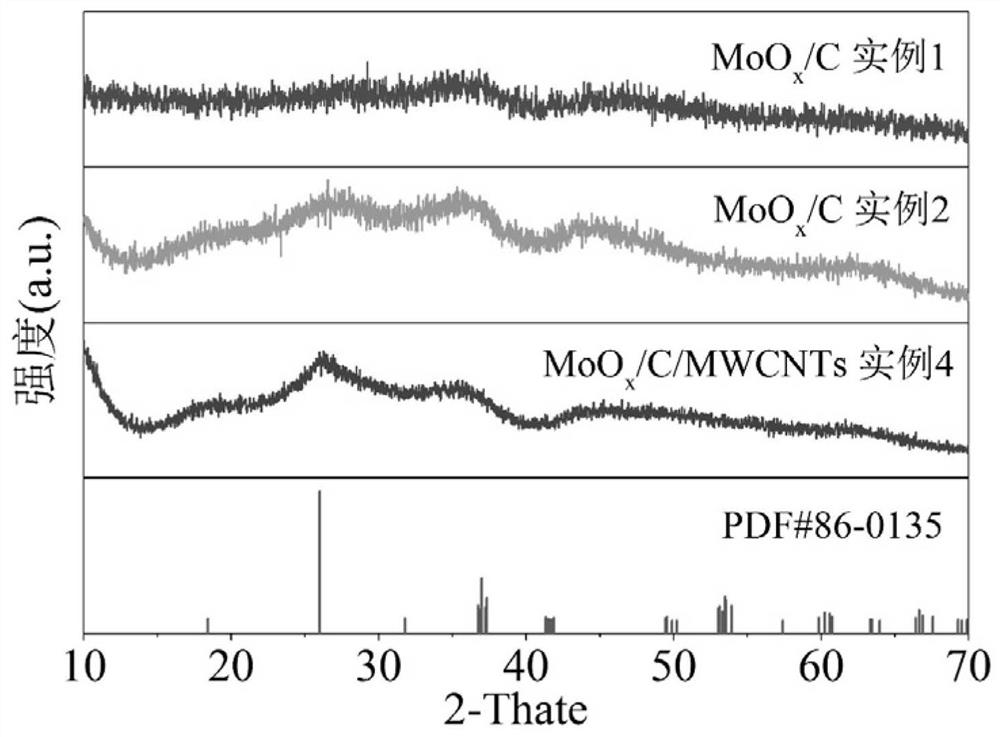

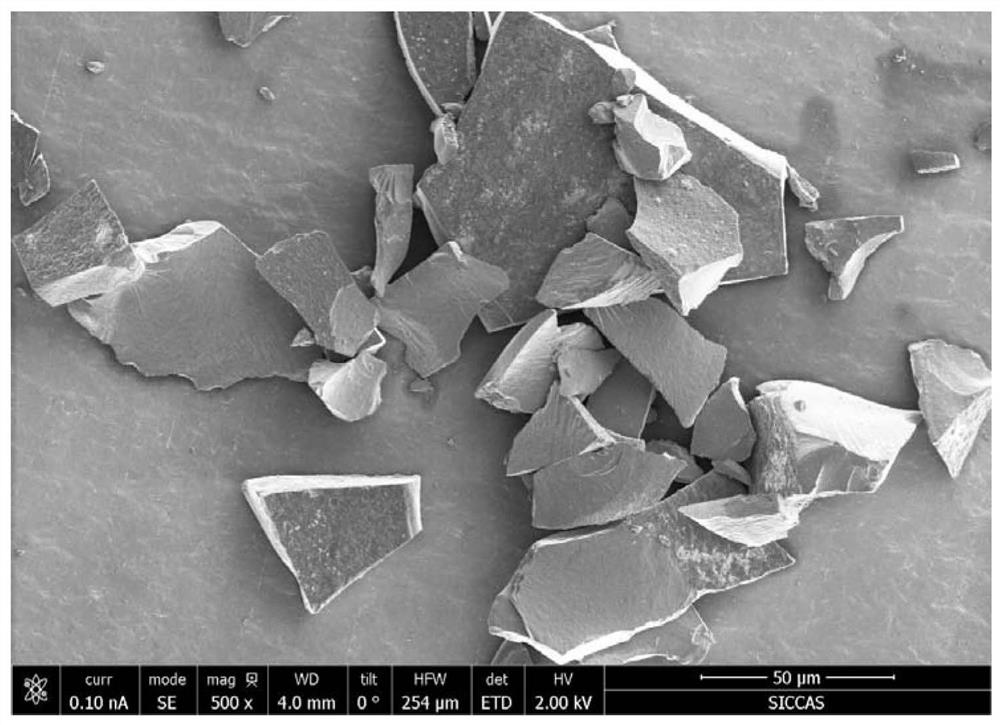

[0039] MoO x / C composite preparation. Specifically, the organic-inorganic complex is synthesized first, and then the complex is used as a precursor to synthesize MoO by pyrolysis. x / C Composite. Specifically, organic-inorganic complex precursors were synthesized by direct complexation of phosphomolybdic acid and organic matter through chemical bonds, and then dense MoO was obtained after sintering. x / C (x=2-3) Micron-order large-sized particles. The present invention is preparing MoO x Simultaneously, the carbon coating is formed in situ, MoO x There is no obvious interface with carbon, and the MoO obtained in the present invention x The morphology of the / C material is dense and large-sized particles in the order of tens of microns. The following exemplifies MoO x / C composite material preparation method.

[0040] Weigh a certain amount of molybdenum oxide precursor (for example, H 3 PMo 12 o 40 ·nH 2 O, ammonium molybdate, etc.) in desolvated (for example, ion...

Embodiment 1

[0051] with H 3 PMo1 2 o 40 ·nH 2 Preparation of MoO with O and Tris(3,6-dioxaheptyl)amine as Precursors x / C negative electrode material:

[0052] According to the molar ratio of 1:3, weigh 0.608g H 3 PMo 12 o 40 ·nH 2 O and 0.323 g tris(3,6-dioxaheptyl)amine. The two materials were dissolved in 30 ml of deionized water, respectively, and stirred for 30 minutes. Add tris(3,6-dioxaheptyl)amine aqueous solution into phosphomolybdic acid aqueous solution, and stir for 4 hours. Then it was centrifuged and washed with water to separate the organic-inorganic complex, and placed in a vacuum oven at 50° C. for 12 hours. The dried organic-inorganic complex was ground in a mortar for 15 minutes. Place the finely ground organic-inorganic complex in a ceramic crucible, put the crucible into a tube furnace, and pass high-purity nitrogen into the tube furnace to remove the air in the furnace tube. After ventilating for 2 hours, heat under a specific program: heating rate 2°C / mi...

Embodiment 2

[0054] with H 3 PMo 12 o 40 ·nH 2 Preparation of MoO with O and Dioctadecyldimethylammonium Bromide as Precursors x / C negative electrode material:

[0055] According to the molar ratio of 1:3, weigh 0.456g H 3 PMo 12 o 40 ·nH 2 O and 0.473 g dioctadecyldimethylammonium bromide. Both materials were dissolved in 20 ml of chloroform, respectively, and stirred for 30 minutes. Add the chloroform solution of dioctadecyldimethylammonium bromide into the chloroform solution of phosphomolybdic acid, and stir for 4 hours. Subsequently, the solvent was evaporated to dryness at 50° C., then transferred to a vacuum oven at 50° C., and dried for 12 hours. The dried organic-inorganic complex was ground in a mortar for 15 minutes. Place the finely ground organic-inorganic complex in a ceramic crucible, put the crucible into a tube furnace, and pass high-purity nitrogen into the tube furnace to remove the air in the furnace tube. After ventilating for 2 hours, heat under a specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com