A method for recovering technetium from spent fuel reprocessing waste liquid

A spent fuel and waste liquid technology, applied in the direction of improving process efficiency, can solve the problems of high price, three-phase problem of trioctylamine and quaternary ammonium salt, low extraction efficiency of TRPO, etc., and achieve the effect of high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

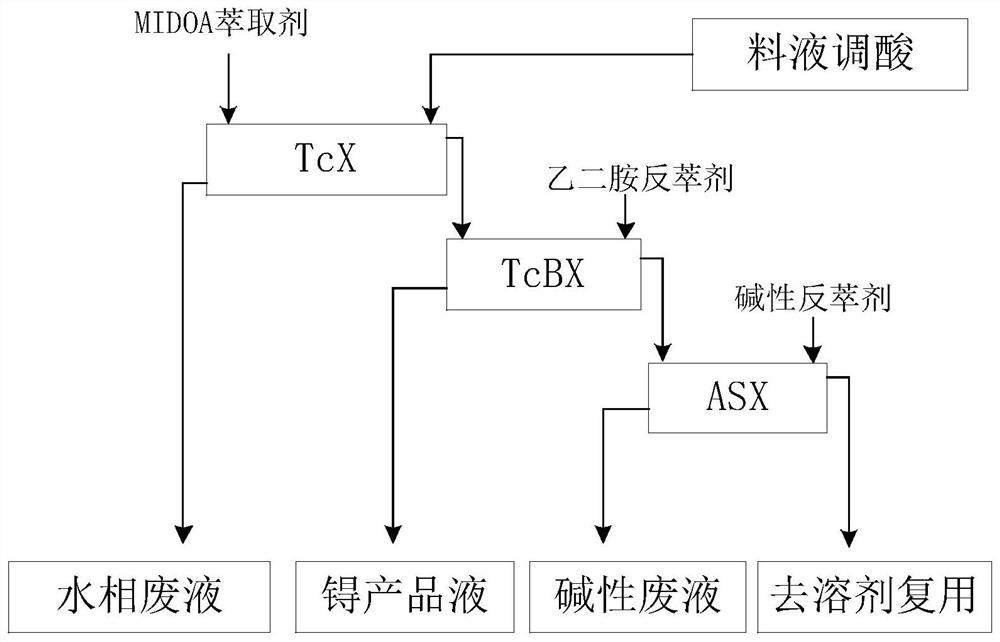

[0043] For the process of this embodiment, see image 3 .

[0044] (1) Material liquid acid adjustment and technetium extraction (TcX): 0.1mol / L MIDOA is used as the extraction agent, kerosene is used as the diluent, 1AXXW is extracted after the acid adjustment to 0.5mol / L, after 6-stage extraction, technetium The recovery rate reaches above 99.99%.

[0045] (2) Technetium back-extraction (TcBX): use 0.2mol / L ethylenediamine to back-extract technetium from the extracted organic phase, and separate it from tetravalent impurity elements. After 6-stage back-extraction, the decontamination of Pu(IV) reaches 100 Above, the yield of technetium reaches 99%.

[0046] (3) An washing (ASX): wash the organic phase with 0.02mol / L ammonium carbonate solution, and the organic phase can be reused after washing.

[0047] Through the above process, the total yield of technetium reaches 99%, the decontamination of plutonium reaches more than 100%, and the decontamination of uranium reaches m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com