Method for leaching rare earth in rare earth-containing porcelain clay ore raw ore

A technology of china clay ore and rare earth, which is applied in the field of comprehensive utilization of raw ore containing rare earth china clay, which can solve the problems of low yield of rare earth, lower quality of high alumina china clay products, ammonia nitrogen pollution, etc., to reduce the leaching rate of impurities, improve quality, and extract efficiently The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

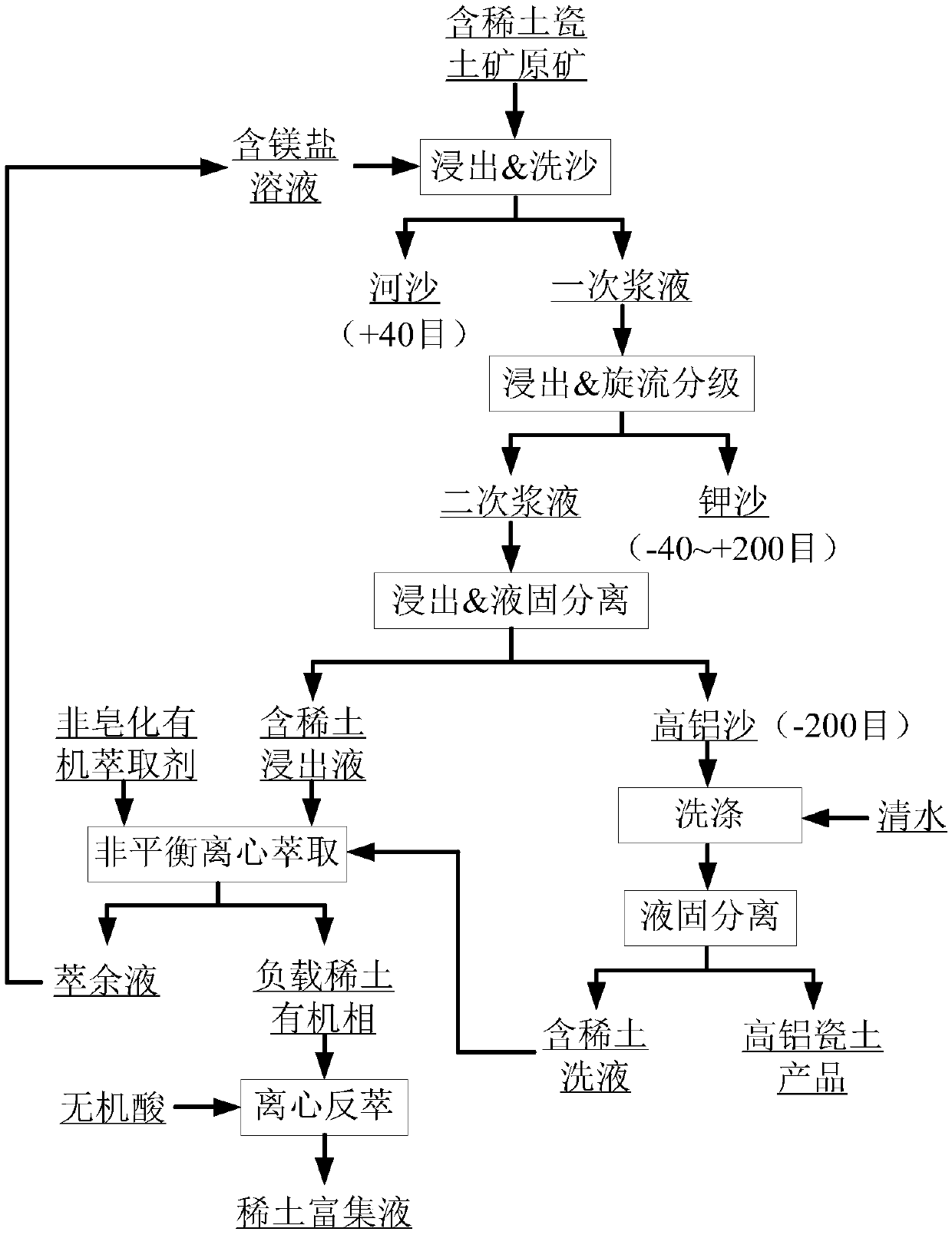

Image

Examples

Embodiment 1

[0046] The object of leaching treatment is raw ore of china clay ore containing rare earth, the mass is 1kg, and the grade of rare earth is 0.05%. The specific process is as follows: step S1, using a magnesium-containing salt solution with a pH value of 2.0 and a cation concentration of 0.01mol / L to stir and leach the raw ore of the china clay ore containing rare earth, the volume-to-mass ratio of the salt solution containing magnesium to the raw ore of the china clay ore containing rare earth is 10.0L / kg, the leaching time is 10h, and after leaching, sand washing treatment is performed to obtain river sand and primary slurry; step S2, Mg 2+ The amount of the substance and the mass ratio of the raw ore are 0.01 magnesium salt solids are added to the primary slurry for stirring and leaching. The leaching time is 10 hours. 2+ Add the magnesium salt solid with a mass ratio of 0.01 to the raw ore to the secondary slurry for stirring and leaching. The leaching time is 10 hours. Wa...

Embodiment 2~14

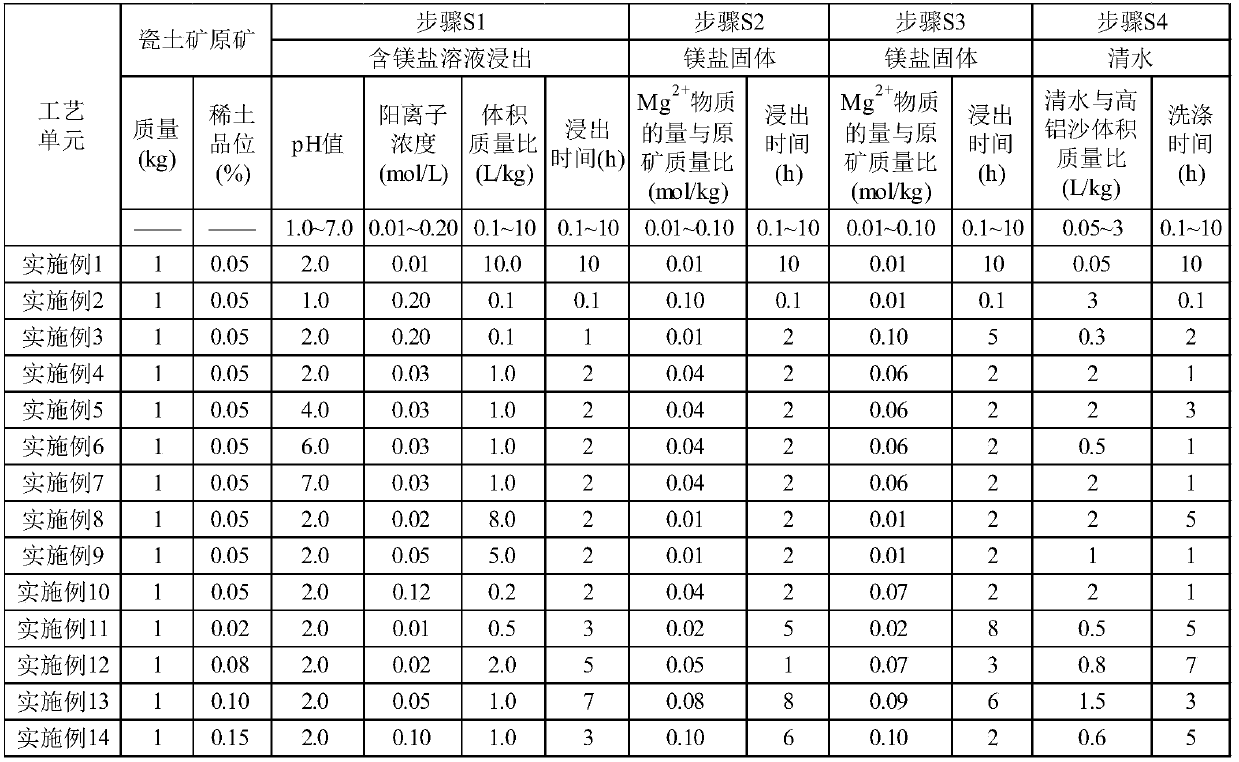

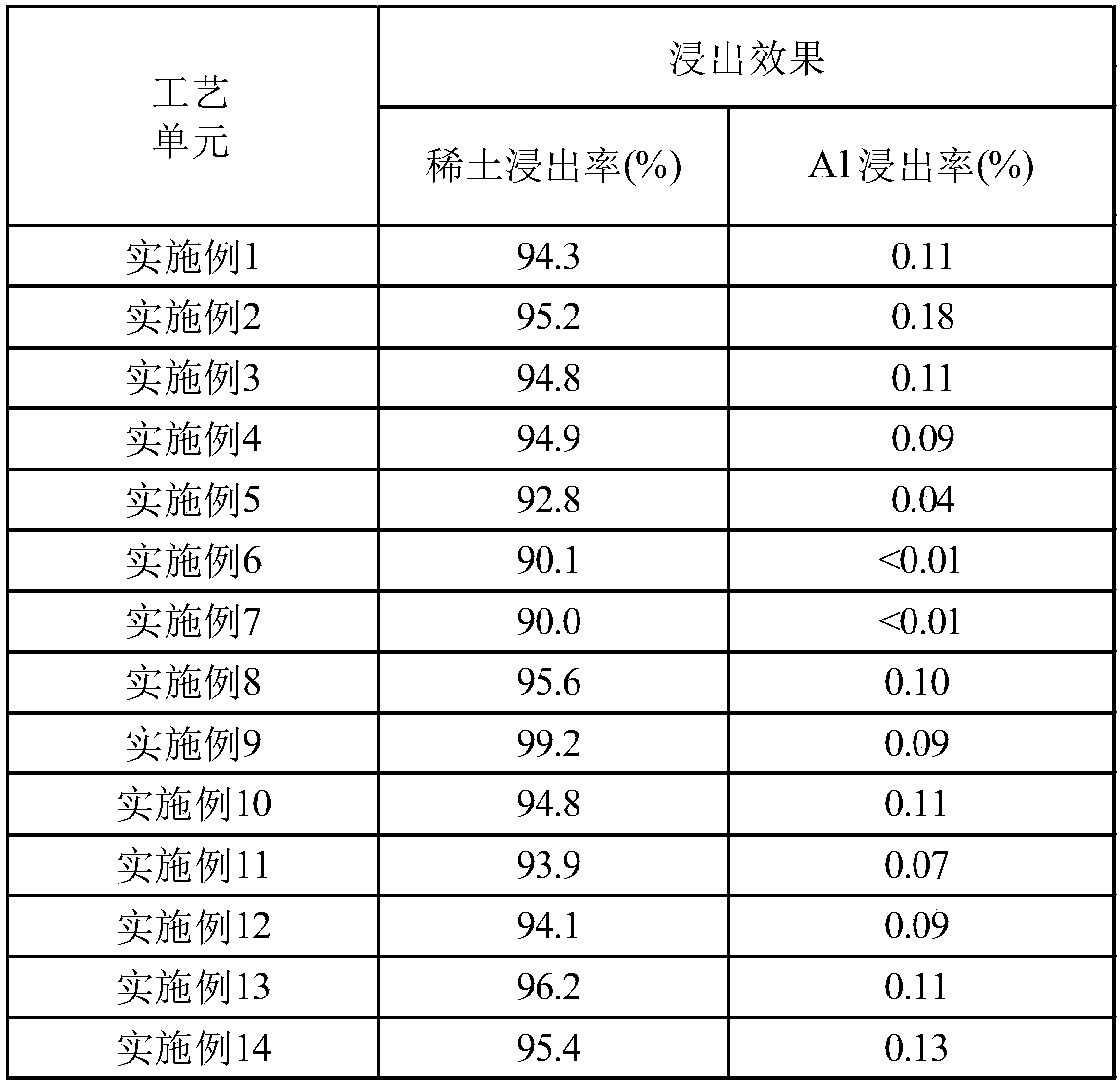

[0048] The steps of Examples 2-14 are the same as those of Example 1. The process conditions shown in Table 1 are used to leach the rare earths in the raw ore of china clay ore containing rare earths. The leaching effects are shown in Table 2.

[0049] Table 1:

[0050]

[0051] Table 2:

[0052]

Embodiment 15

[0058] The leaching treatment object is the same as that of Example 4, which is the raw ore of china clay ore containing rare earth, with a mass of 1 kg and a rare earth grade of 0.05%. The specific process is as follows: step S1-S4 multi-stage leaching is according to Example 4, the leaching rate of rare earth is 94.9%, and the leaching rate of Al is 0.09%. Afterwards, after combining the rare earth-containing leaching solution and the rare earth-containing lotion into a rare earth-containing solution, the rare earth is recovered by non-equilibrium extraction and enrichment, including: step S5, using an organic extractant P507 with a concentration of 0.5mol / L to extract the rare earth-containing solution Non-saponification and non-equilibrium centrifugal extraction, the volume flow ratio (O / A) is 1:15, and the contact time is 10S to obtain the loaded rare earth organic phase and raffinate; step S6, using a concentration of 5mol / L inorganic acid to load The rare earth organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com