A graphene/silicon carbide nanowire composite structure thermal interface material

A technology of silicon carbide nanowires and thermal interface materials, applied in the field of chemical materials, can solve the problems of low out-of-plane thermal conductivity and difficulty in meeting heat dissipation requirements, and achieve low out-of-plane thermal conductivity and increase out-of-plane thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation of the thermal interface material comprises the following steps:

[0070] (1) Graphene oxide sheets and graphene sheets modified by silica nanoparticles are mixed in ethanol at a mass ratio of 1:10 to obtain a dispersion;

[0071] (2) the dispersion liquid in suction filtration step (1) obtains thin film, i.e. composite graphene paper;

[0072] (3) The film (composite graphene paper) in step (2) is subjected to high-frequency heat treatment to obtain the thermal interface material.

Embodiment 1

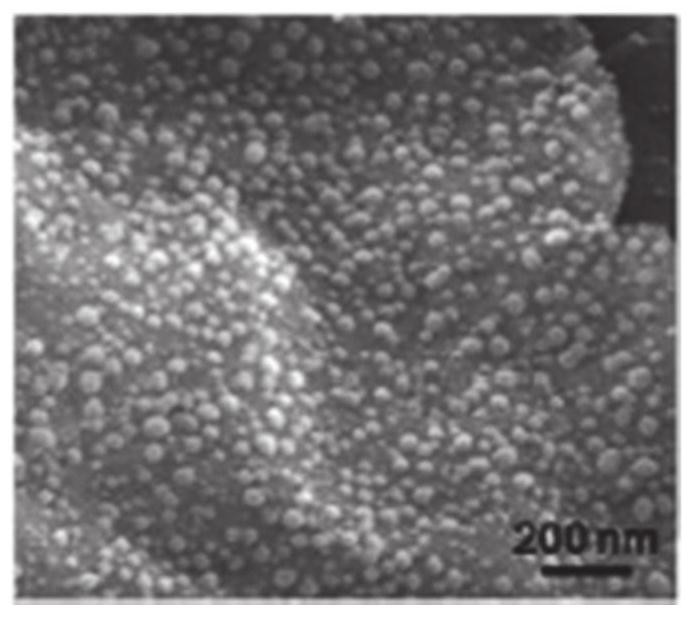

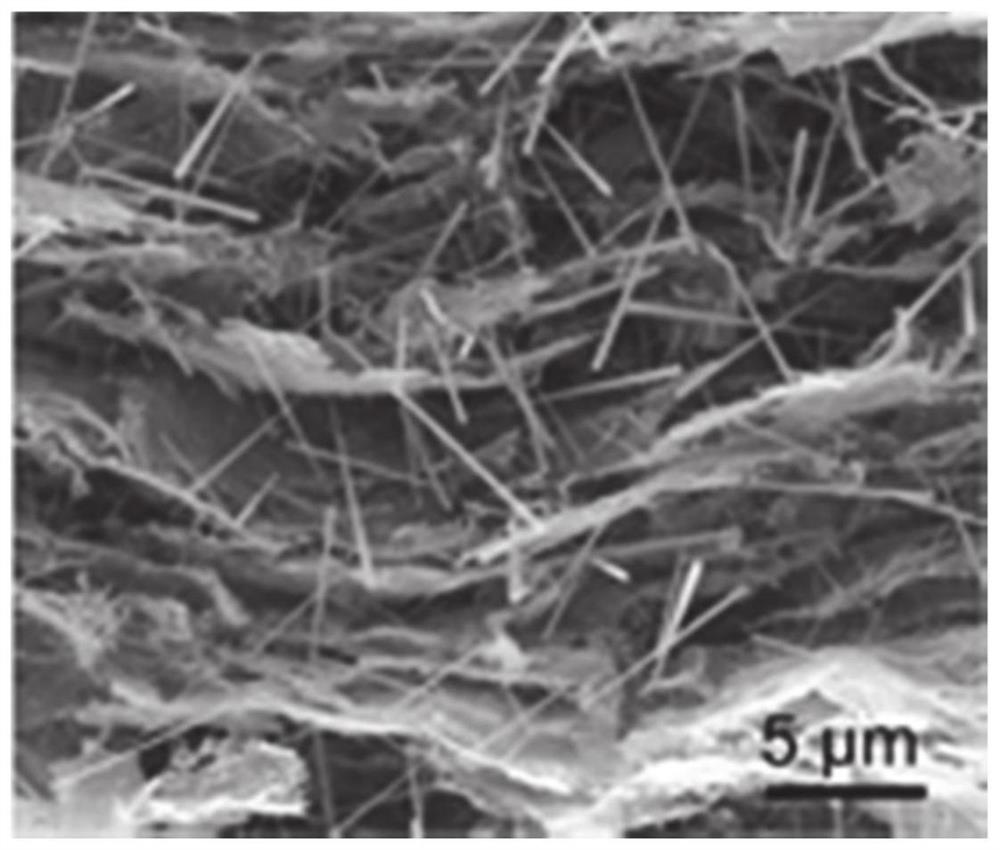

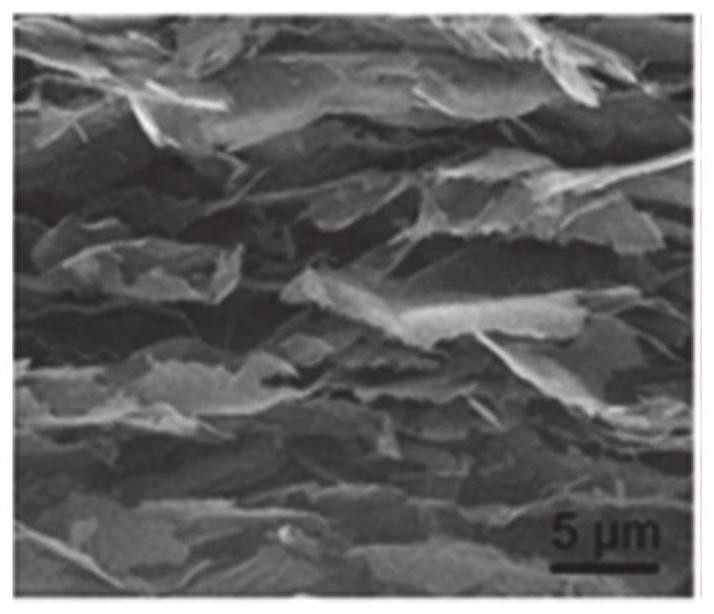

[0074] Disperse 120 mg of graphene oxide in a mixed solution of 240 mL of ethanol and 24 mL of deionized water, and sonicate for 120 min. Add 4mL ammonia water and 0.5mL tetraethyl orthosilicate, and sonicate for 180min. Vacuum filter and wash several times with deionized water, dry. Weigh 20 mg of dried powder and 180 mg of graphene sheets and disperse them in ethanol, ultrasonicate, and suction filter to obtain composite graphene paper. The suction-filtered film (composite graphene paper) was heated at 1400°C for 4 minutes at high frequency (frequency 250kHz) to obtain silicon carbide nanowire / graphene sheet hybrid paper, which is the thermal interface material described above, which is designated as sample 1#.

Embodiment 2

[0076] Disperse 120 mg of graphene oxide in a mixed solution of 240 mL of ethanol and 24 mL of deionized water, and sonicate for 120 min. Add 4mL ammonia water and 0.5mL tetraethyl orthosilicate, and sonicate for 180min. Vacuum filter and wash several times with deionized water, dry. Weigh 20 mg of dried powder and 180 mg of graphene sheets and disperse them in ethanol, ultrasonicate, and suction filter to obtain composite graphene paper. The suction-filtered film (composite graphene paper) was heated at 1400°C for 4 minutes at high frequency (frequency 300kHz), and then a pressure of 75 psi was applied to the film to obtain silicon carbide nanowire / graphene sheet hybrid paper, which is the thermal interface material , recorded as sample 2#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com