Three-network copolymerized castable for bus duct

A bus duct and castable technology, which is applied in the field of castables for bus duct, can solve problems such as poor load resistance and cracking, and achieve the effects of good load capacity, extended service life, and excellent waterproof and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

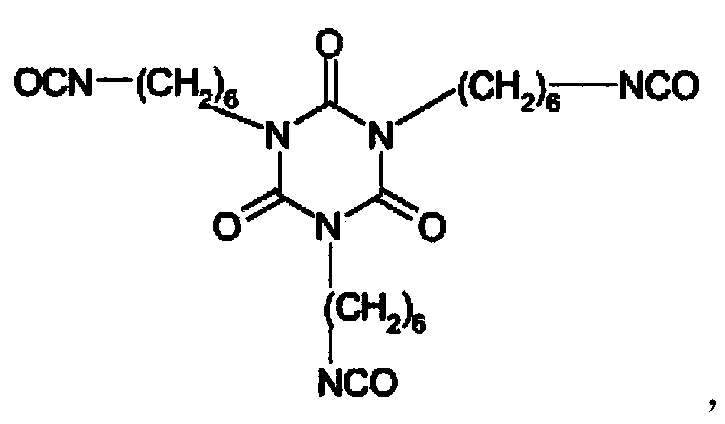

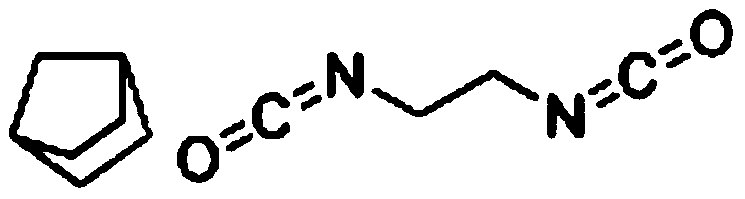

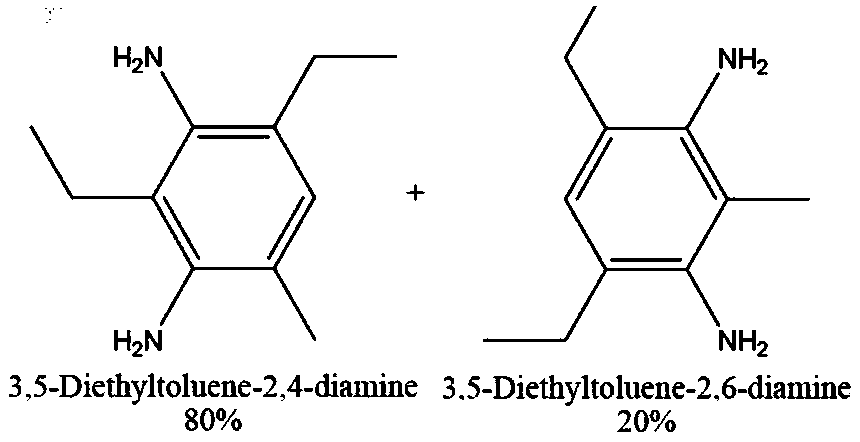

[0027] Take 10 parts of prepolymers of HDI trimers, 35 parts of prepolymers of NBDI and polyether polyols, 10 parts of epoxy resin E51 in parts by mass, fully stir, and let stand for 0.5h; E100, 10 parts of aluminum hydroxide powder, 20 parts of aluminum oxide, 20 parts of short glass fiber shreds and mixed, fully stirred and then vacuumed, poured into the placed mold, solidified at room temperature, demolded to obtain the target material.

Embodiment 2

[0029] Take 20 parts of prepolymers of HDI trimers, 15 parts of prepolymers of NBDI and polyether polyols, and 15 parts of epoxy resin E54 in parts by mass, fully stir, and let stand for 0.5h; E300, 20 parts of aluminum hydroxide powder, 10 parts of aluminum oxide, and 20 parts of short glass fiber shreds are mixed, fully stirred and then vacuumed, poured into a placed mold, cured at room temperature, and demolded to obtain the target material.

Embodiment 3

[0031] Take 35 parts of prepolymers of HDI trimer and 20 parts of prepolymers of NBDI and polyether polyols in parts by mass, fully stir, and let stand for 0.5h; then mix with the calculated amount of E100, 30 parts of aluminum hydroxide Powder, 10 parts of alumina, 10 parts of short glass fiber shreds are mixed, fully stirred and then vacuumed, poured into a placed mold, cured at room temperature, and demolded to obtain the target material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com