Capacitive deionization electrode, preparation method thereof and capacitive deionization device

A technology of capacitive deionization and electrodes, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of increasing the processing difficulty of CDI devices, achieve the effects of reducing common ion repulsion, enhancing toughness, and enhancing desalination effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

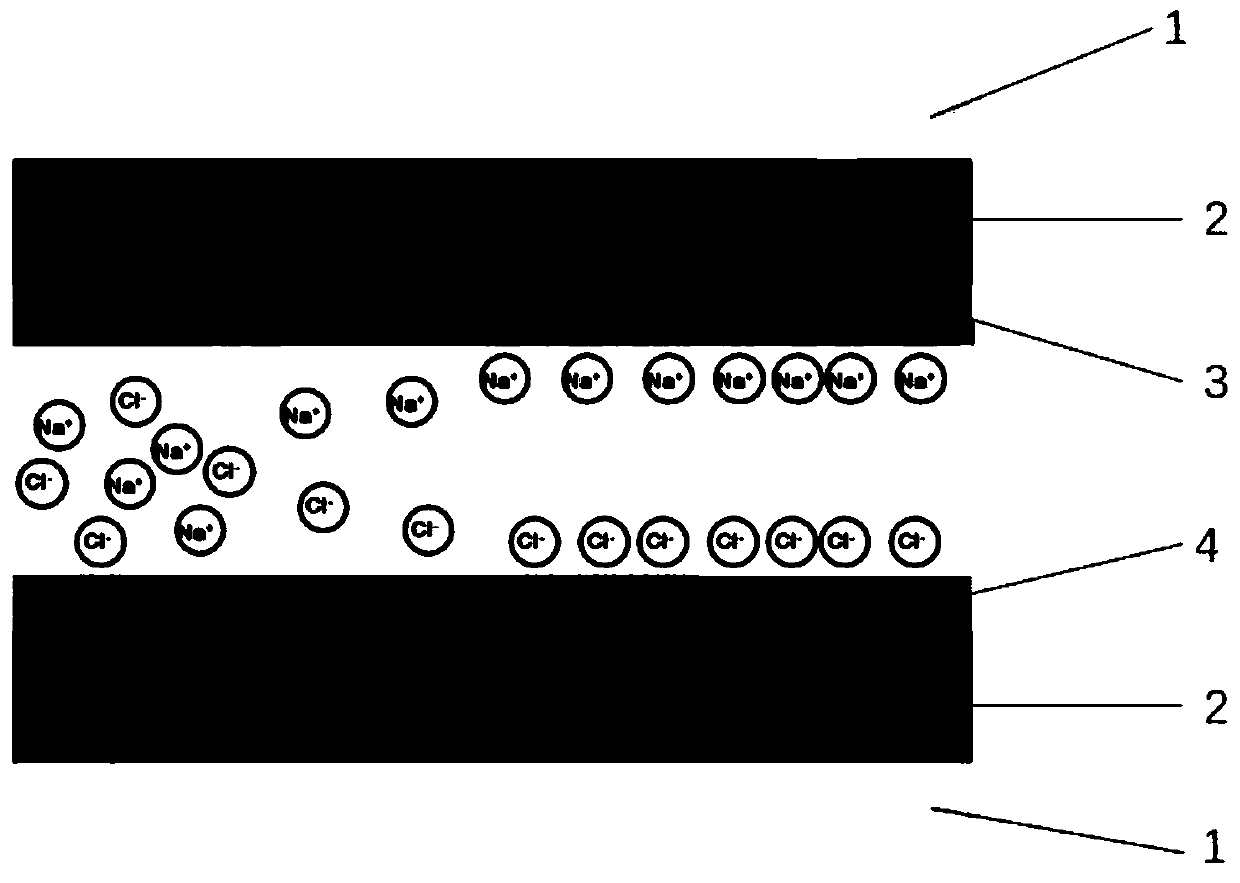

[0056] The present invention also provides a preparation method of a capacitive deionization electrode, comprising the following steps:

[0057] S1: Preparation of the substrate electrode:

[0058] Mixing the carbon material with a conductive agent and a binder to obtain an electrode slurry, coating the electrode slurry on a current collector, and drying in a vacuum to obtain a base electrode;

[0059] Specifically, the mass ratio of the active components of the carbon material in the electrode slurry is greater than or equal to 90%;

[0060] Further, the mass ratio of conductive agent and adhesive is 1:1;

[0061] Specifically, the carbon material is selected from any one of activated carbon, graphene, carbon fiber, and carbon tube, but not limited thereto, and the carbon material is selected from a carbon material with a large specific surface area, developed pores, and good hydrophilicity;

[0062] S2: Preparation of positive electrode:

[0063] After defoaming the scrap...

Embodiment 1

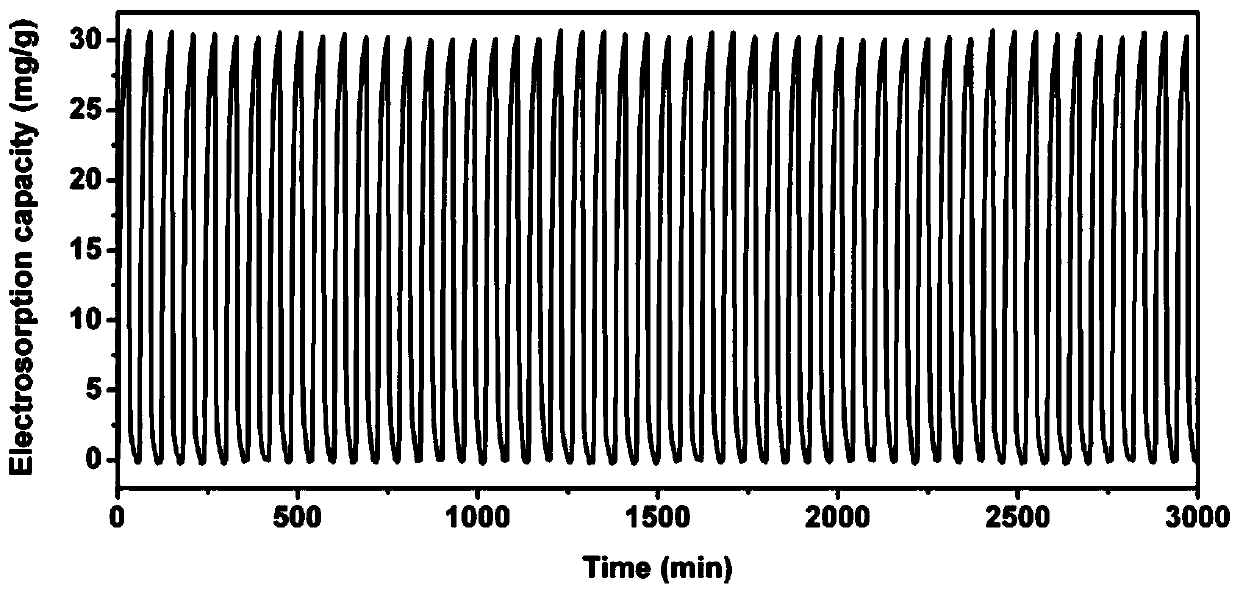

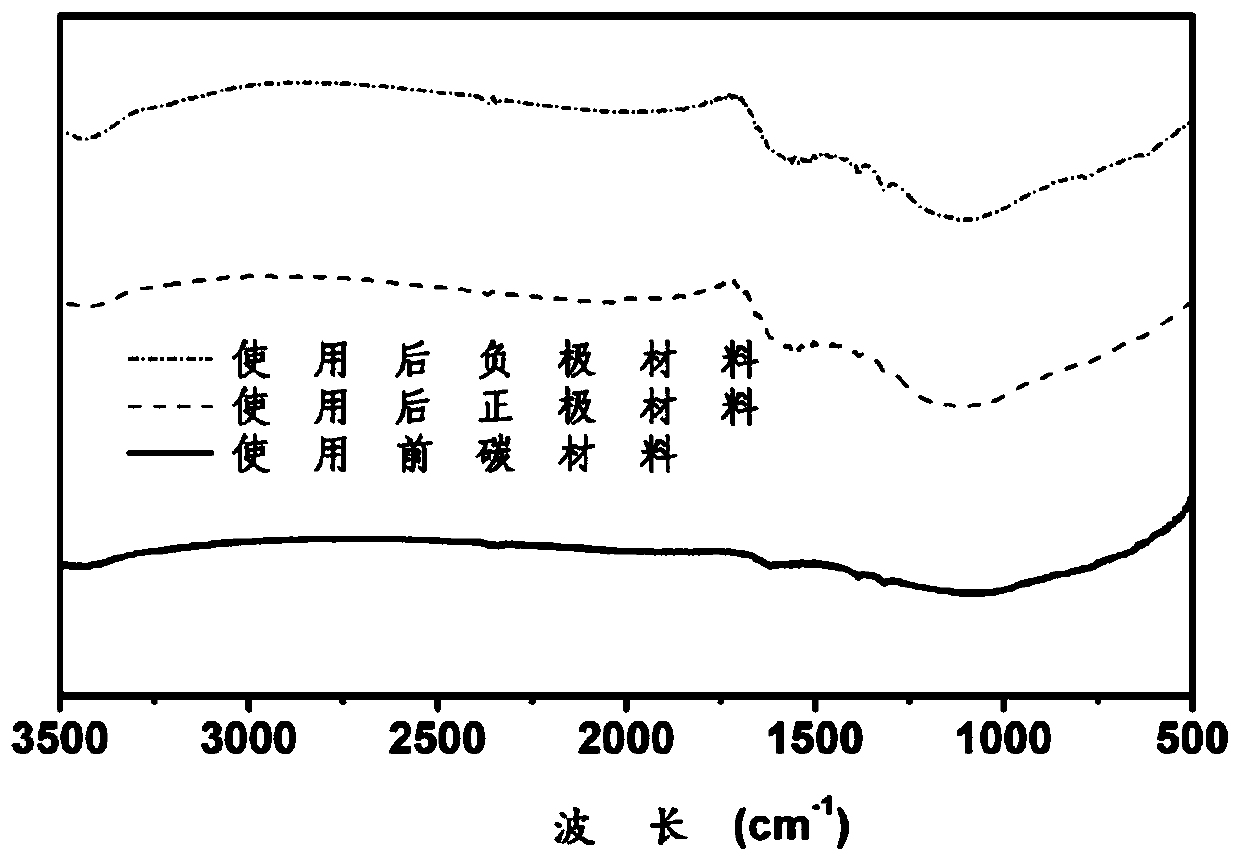

[0081] This embodiment provides a method for preparing a long-life, high-efficiency capacitive deionization electrode, which specifically includes the following steps:

[0082] (1) Preparation of the base electrode

[0083] The active carbon material, conductive carbon black, and polyvinylidene fluoride are uniformly mixed at a mass ratio of 90:5:5 to obtain an electrode slurry, which is then uniformly coated on graphite paper and dried under vacuum at 80°C to obtain the electrode slurry. Base electrodes on the positive and negative electrodes.

[0084] (2) Preparation of positive electrode

[0085] The dry chloroacetylated polyphenylene ether was dissolved in N,N-dimethylformamide to form a scraping solution with a mass fraction of 15%, and then moved into a vacuum oven to stand for defoaming. Evenly scrape the defoamed scraping solution on the activated carbon material side of the base electrode, let it stand at room temperature for 24 hours, then move it into a vacuum ove...

Embodiment 2

[0089] This embodiment provides a method for preparing a long-life, high-efficiency capacitive deionization electrode, which specifically includes the following steps:

[0090] (1) Preparation of the base electrode

[0091] The active carbon material, conductive carbon black, and polyvinylidene fluoride are uniformly mixed at a mass ratio of 90:5:5 to obtain an electrode slurry, which is then uniformly coated on graphite paper and dried under vacuum at 80°C to obtain the electrode slurry. Base electrodes on the positive and negative electrodes.

[0092] (2) Preparation of positive electrode

[0093]Dissolve dry chloroacetylated polyphenylene ether and brominated poly(2,6-dimethyl-1,4-polyphenylene ether) in N,N-dimethylformamide at a mass ratio of 3:7 to form The scraping solution with a mass fraction of 15% was then moved into a vacuum oven to stand still for degassing. Evenly scrape the defoamed scraping solution on the activated carbon material side of the base electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com