Molecular sieve/porous carbon composite electrode material for capacitive adsorption desalination and preparation method thereof

A porous carbon material, capacitive adsorption technology, applied in separation methods, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of reducing desalination efficiency and electrode efficiency, increasing energy consumption, and limiting the application of porous carbon electrode materials, etc. Achieve the effect of facilitating ion diffusion and adsorption, reducing repulsion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take H-type β molecular sieve HSZ-1 with high silicon content as the doping component, and its properties are as follows: SiO 2 / Al 2 o 3 The molar ratio is 40:1, and the specific surface area is 530m 2 / g, the particle diameter is about 4 microns.

[0034] Preparation concentration is the dispersion liquid (dispersion in deionized water) of 50mg / mL activated carbon and HSZ-1 molecular sieve, adds PTFE emulsion (mass fraction 60%), activated carbon, HSZ-1 molecular sieve and PTFE mass ratio are 90:10:7, After mechanical stirring for 2 hours, dry in an oven at 95°C to obtain a flocculent molecular sieve / activated carbon mixture. A small amount of ethanol was added to the resulting mixture for wetting, rolled into a sheet and pressed on a titanium mesh to obtain an HSZ-1 / activated carbon (HSZ-1 / AC) electrode.

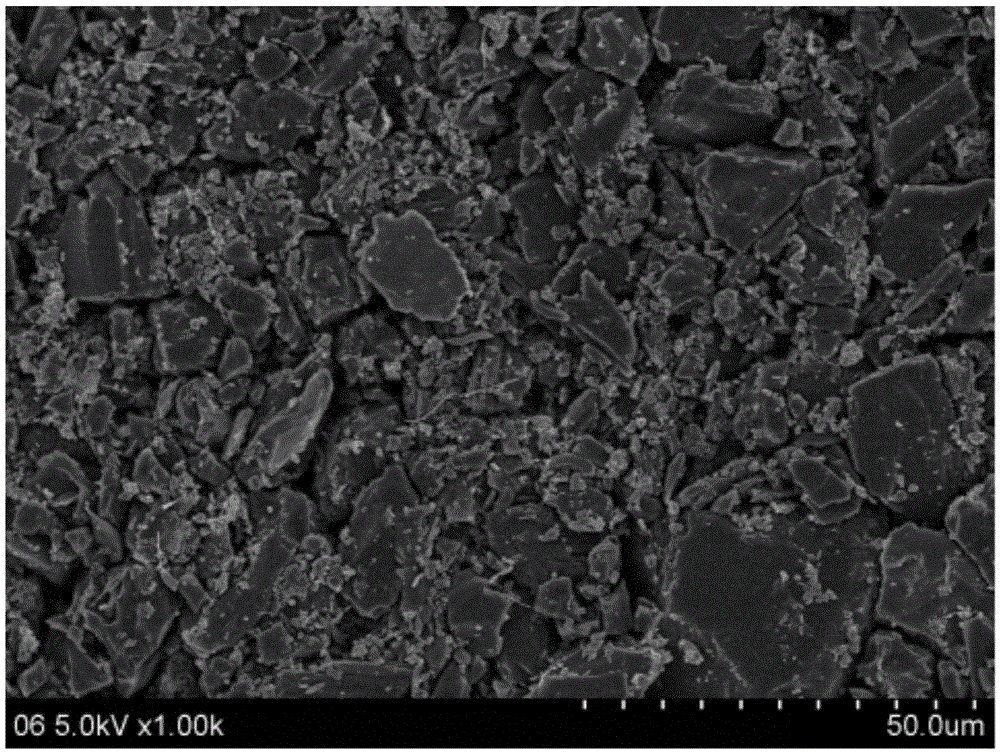

[0035] figure 1 It is the SEM topography image of HSZ-1 / AC electrode.

[0036] Assemble an asymmetric capacitive desalination device, use the molecular siev...

Embodiment 2

[0038] Take Na-type mordenite molecular sieve HSZ-2 with high silicon content as the doping component, and its properties are as follows: SiO 2 / Al 2 o 3 The molar ratio is 18:1, Na 2 O / Al 2 o 3 The molar ratio is 1:1, and the particle diameter is about 12 microns.

[0039] Preparation concentration is the dispersion liquid (dispersion in deionized water) of 50mg / mL activated carbon and HSZ-2 molecular sieve, adds PTFE emulsion (mass fraction 60%), activated carbon, HSZ-2 molecular sieve and PTFE mass ratio are 90:10:7, After mechanical stirring for 2 hours, dry in an oven at 95°C to obtain a flocculent molecular sieve / activated carbon mixture. A small amount of ethanol was added to the obtained HSZ-2 / activated carbon mixture for wetting, rolled into a sheet and pressed on a titanium mesh to obtain an HSZ-2 / activated carbon (HSZ-2 / AC) electrode. image 3 It is the SEM topography of HSZ-2 / AC electrode.

[0040] Assemble an asymmetric capacitive desalination device, use t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com