Composite positive osmosis membrane and preparation method thereof

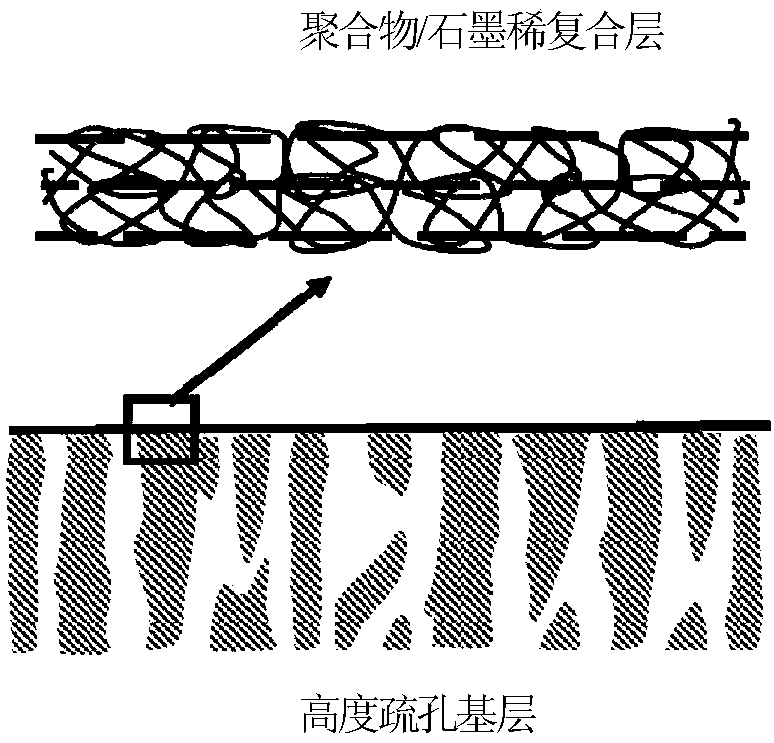

A forward osmosis membrane and graphene composite technology, applied in the field of composite forward osmosis membrane and its preparation, can solve the problems of unreachable, low forward osmosis membrane flux, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve 1g of isopropylacrylamide monomer and 1g of N,N-methylene bisacrylamide monomer in 20g of water, add 0.2g of sodium persulfate as an initiator; then add 0.1g of flake graphene to obtain the final precursor solution. And coating the nylon membrane with micron pores by spin coating, then heating at 70oC for two hours, and repeating the two steps of coating and heat treatment three times to obtain the final forward osmosis membrane.

[0027] figure 2 It is the scanning electron microscope (SEM) figure of the surface and the cross-section of the made forward osmosis membrane, a) the intercepting layer surface, b) the composite membrane cross-section; from which we can see that the surface of the membrane is uniform and dense, no leaks are seen, It can be seen from the cross-sectional view of the membrane that the thickness of the selective layer of the membrane is very thin, about 100 nanometers.

[0028] The test results of the water flux and salt rejection rat...

Embodiment 2

[0030] A film was prepared in a method similar to that of Example 1, except that the mass of graphene flakes was changed to 1.4 g, and a film with a similar structure was obtained.

[0031] The test results of the water flux and salt rejection rate of the membrane show that when using 1mol L -1 The NaCl solution is used as the extraction solution, the water flux of the membrane is 23.0LMH, and its reverse salt flux is 1.2g m -2 h -1 .

Embodiment 3

[0033] Adopt the method similar to embodiment 1 to make film, just change the quality of flake graphene into 0.05g, obtain the film with similar structure.

[0034] The test results of the water flux and salt rejection rate of the membrane show that when using 1mol L -1 The NaCl solution is used as the extraction solution, the water flux of the membrane is 25.9LMH, and its reverse salt flux is 1.5g m -2 h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com