Underwater manifold connecting piece manufacturing technology and underwater manifold connecting piece

A manufacturing process and connector technology, applied in the manufacturing field of key components of underwater production systems, can solve the problems of high operation and maintenance costs, increase corrosion resistance life, unstable product quality, etc., to reduce operation and maintenance costs and increase corrosion resistance. The effect of life and forging technology control optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

[0023] An underwater manifold connector is manufactured according to the following steps:

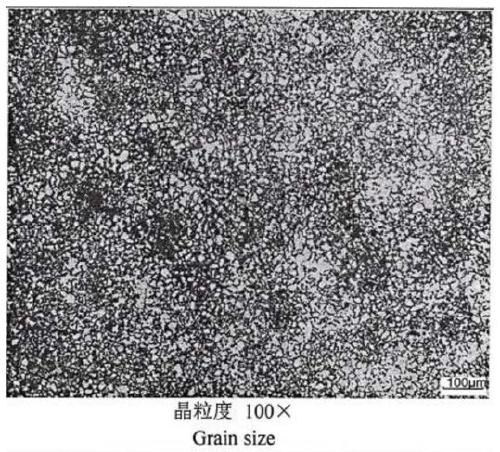

[0024] Manufacture of S10 Substrate

[0025] S11 forging, using A694-F65 as the base material for forging, the A694-F65 base material includes by weight: C: 0.16%, Si: 0.31%, Mn: 1.26%, P: 0.013%, S: 0.007%, Cr : 0.12%, Ni: 0.22%, Mo: 0.03%, Cu: 0.13%, Ti: 0.004%, Nb: 0.013%, Al: 0.036%, V: 0.010%, B: 0.0003%, Ca: 0.0018%, and the rest It is Fe, carbon equivalent Ce<0.425; forging temperature is controlled within 850-1180°C; furnace cooling is performed after forging, and furnace cooling can achieve the effect of hydrogen expansion;

[0026] S12 normalizing, normalizing after the furnace cooling is completed, eliminating banded structure and segregation, and achieving the purpose of homogenization treatment.

[0027] S13 mechanical processing, complete normalizing forgings for turnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com