Acetic acid bacteria freeze-dried powder and preparation method thereof

A technology of acetic acid bacteria and freeze-dried powder, which is applied in the direction of biochemical equipment and methods, methods based on microorganisms, bacteria, etc., can solve the problems of easy death, low number of viable acetic acid bacteria, and few types of acetic acid bacteria, so as to improve the activity Bacterial count, reduce vitality damage, and realize the effect of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

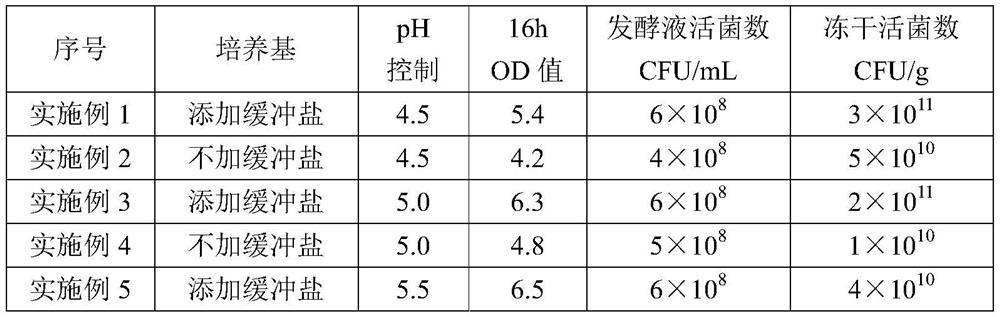

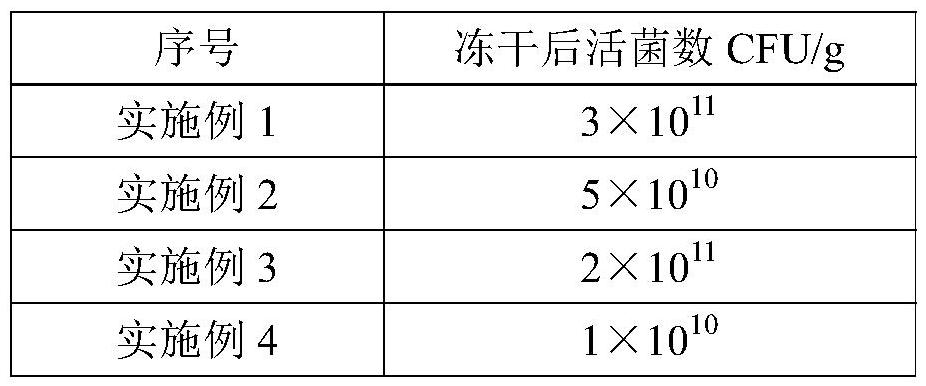

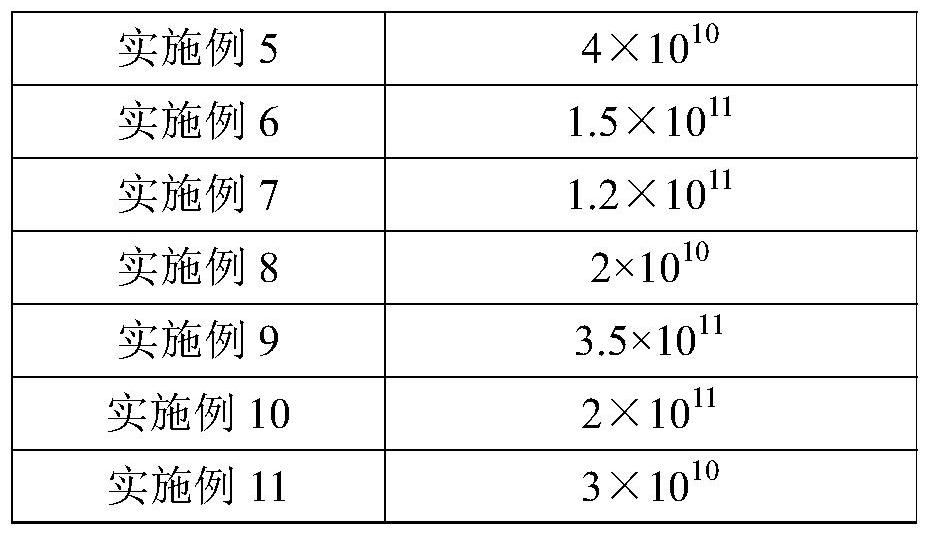

Embodiment 1

[0030] Embodiment 1 preparation of gluconoacetic acid bacteria powder

[0031] 1. Reagents

[0032] (1) Seed medium: glucose 20g / L, peptone 10g / L, yeast powder 20g / L, K 2 HPO 4 2.5g / L, KH 2 PO 4 2.5g / L, MgSO 4 ·7H 2 O 0.1g / L, MnSO 4 0.05g / L, Tween-80 1mL / L.

[0033] (2) Fermentation medium: glucose 50g / L, peptone 10g / L, yeast powder 20g / L, K 2 HPO 4 2.5g / L, KH 2 PO 4 2.5g / L, MgSO 4 ·7H 2 O 0.1g / L, MnSO 4 0.05g / L, Tween-80 1mL / L.

[0034] (3) Lyoprotectant: 10% trehalose, 5% sucrose, 5% maltodextrin, 2% glycerin, 2% gum arabic, the pH of the lyoprotectant is 5.0.

[0035] 2. Experimental method:

[0036] Take the acetic acid bacteria preserved glycerol tube and inoculate the shake flask seed culture medium according to the inoculum amount of 2%, and cultivate at a constant temperature of 30°C for 16 hours to obtain the seed liquid; inoculate the seed liquid into the fermenter according to the inoculum amount of 2% (v / v), Do not add alkali in the early stage, ...

Embodiment 2

[0038] Compared with Example 1, the present embodiment 2 is different in that the acetic acid bacteria seeds and the fermentation medium of the present embodiment do not add buffer salt (K 2 HPO 4 、KH 2 PO 4 ), all the other operating steps are consistent with embodiment 1.

Embodiment 3

[0040] Compared with Example 1, the difference between Example 3 and Example 1 is that when the pH of the system is reduced to 4.5 during the fermentation process, sodium hydroxide is used to control the pH to be stable at about 5.0, and the remaining operation steps are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com