Water-ether mixed electrolytic solution for lithium ion battery, and preparation method thereof

A technology of lithium-ion batteries and electrolytes, applied in aqueous electrolytes, secondary batteries, circuits, etc., can solve the problems of unfavorable lithium ion transmission, large internal resistance of batteries, low conductivity, etc., achieve multiple selectivity, and inhibit hydrogen evolution reaction , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Put 3.0135g LiN(SO 2 CF 3 ) 2 Dissolve in 0.5g ultrapure water, and stir for 24 hours to obtain solution A;

[0031] 2.662g LiN(SO 2 CF 3 ) 2 Dissolve in 0.8515g tetraethylene glycol dimethyl ether, and stir for 24h to obtain solution B;

[0032] (2) Mix solution A and solution B prepared in step (1) according to a mass ratio of 1:1 and stir evenly to obtain a 14.6 mol / L water-ether mixed electrolyte for lithium ion batteries.

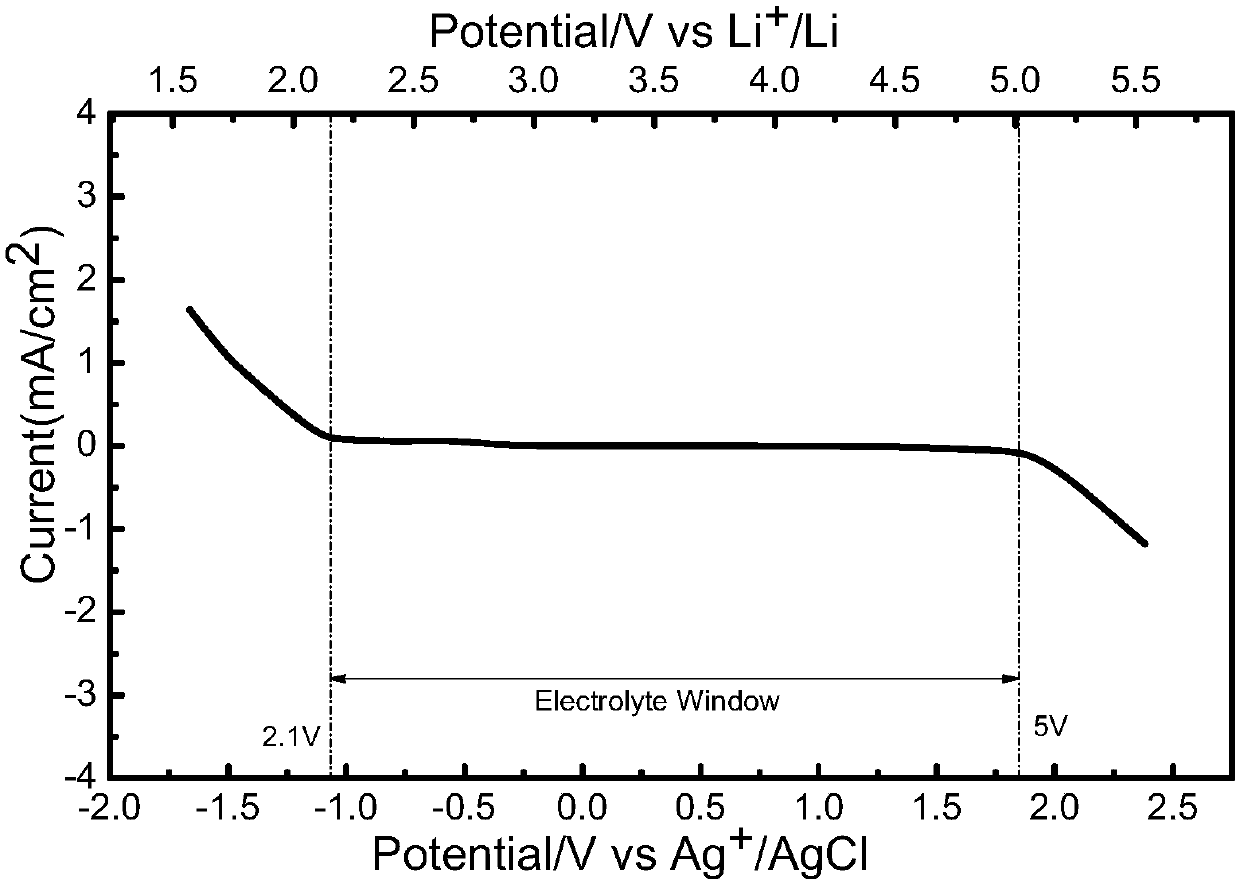

[0033] From figure 1 It can be seen from the electrochemical window diagram in the figure that the mixed electrolyte prepared in this example has a wide electrochemical window, about 3V. After testing, it can be known that the conductivity of the mixed electrolyte solution prepared in this example at room temperature is 7.8×10 -3 S / cm.

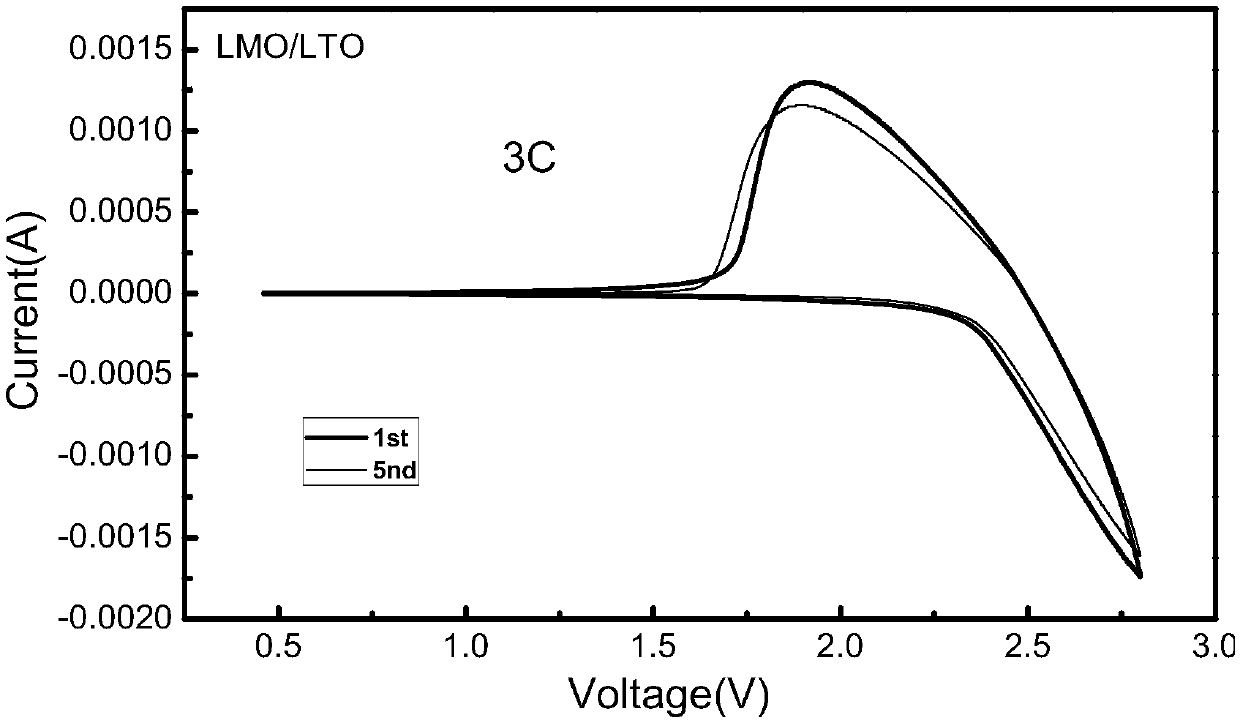

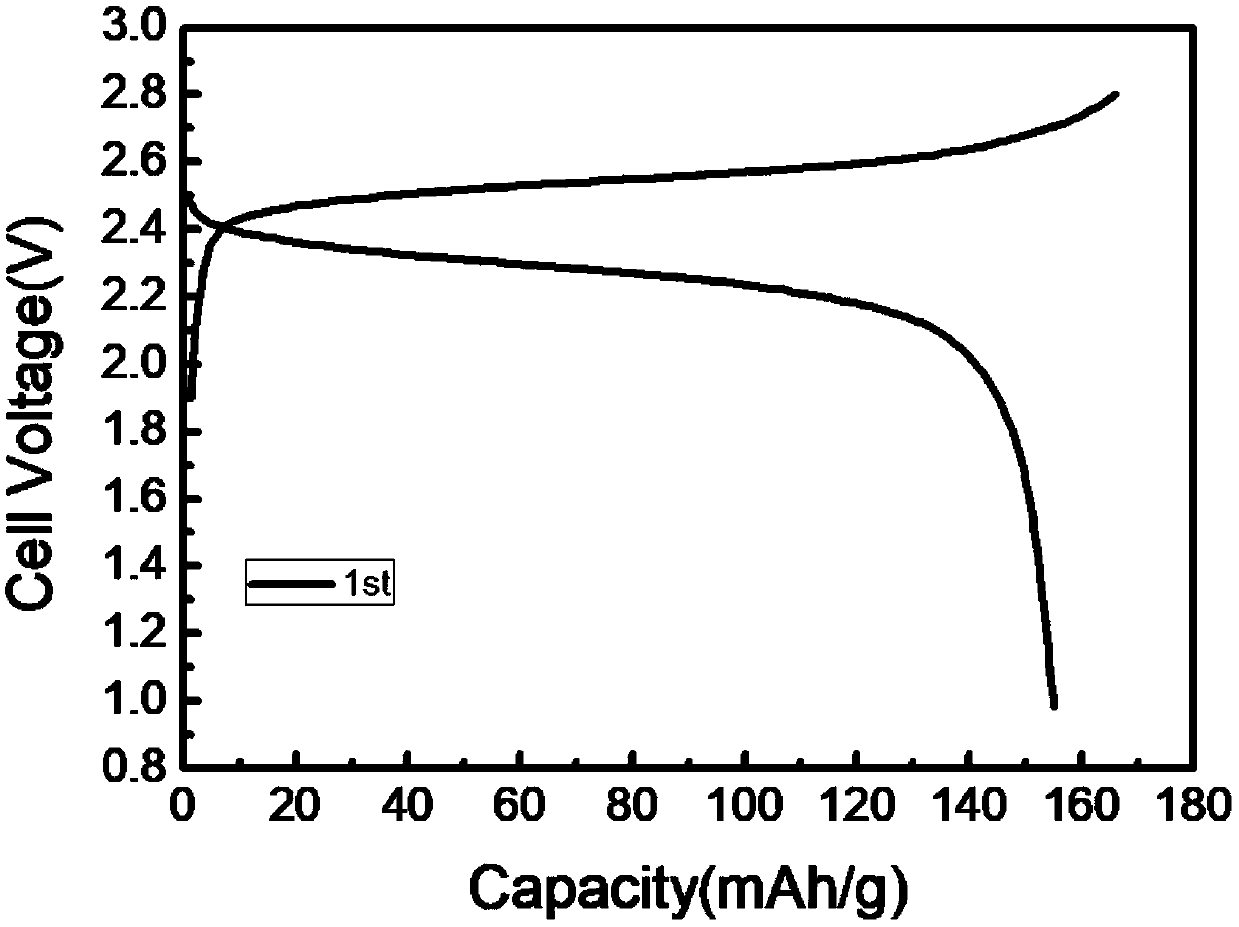

[0034] The mixed electrolyte prepared in this embodiment and LiMn 2 o 4 / Li 4 Ti 5 o 12 Assemble into full cells and perform electrochemical performance tests. From figure 2 It can be seen tha...

Embodiment 2

[0036] (1) Put 3.0135g LiN(SO 2 CF 3 ) 2 Dissolve in 0.5g ultrapure water, and stir for 24 hours to obtain solution A;

[0037] 2.662g LiN(SO 2 CF 3 ) 2 Dissolve in 0.8515g tetraethylene glycol dimethyl ether, and stir for 24h to obtain solution B;

[0038] (2) Mix solution A and solution B prepared in step (1) according to a mass ratio of 2:1 and stir evenly to obtain a 16.4mol / L water-ether mixed electrolyte for lithium ion batteries.

[0039] After testing, it can be known that the window of the mixed electrolyte prepared in this example is 1.9V~5V, and its conductivity at room temperature is 9×10 -3 S / cm.

[0040] The mixed electrolyte prepared in this embodiment and LiMn 2 o 4 / Li 4 Ti 5 o 12 Assemble into full cells and perform electrochemical performance tests. After testing, it can be known that the full battery has a pair of redox peaks around 1.7V and 2.6V; the first week charge and discharge capacity of the full battery at 3C rate is about 16 8mAh / g, an...

Embodiment 3

[0042] (1) Put 3.0135g LiN(SO 2 CF 3 ) 2 Dissolve in 0.5g ultrapure water, and stir for 24 hours to obtain solution A;

[0043] 2.662g LiN(SO 2 CF 3 ) 2 Dissolve in 0.92g triethylene glycol dimethyl ether, and stir for 24h to obtain solution B;

[0044] (2) Mix solution A and solution B prepared in step (1) according to a mass ratio of 1:1 and stir evenly to obtain a 14.0 mol / L water-ether mixed electrolyte for lithium ion batteries.

[0045] After testing, it can be known that the window of the mixed electrolyte prepared in this example is 1.8V-4.9V, and its conductivity at room temperature is 6×10 -3 S cm -1 .

[0046] The mixed electrolyte prepared in this embodiment and LiMn 2 o 4 / Li 4 Ti 5 o 12 Assemble into full cells and perform electrochemical performance tests. After testing, it can be known that the full battery has a pair of redox peaks around 1.65V and 2.7V; the first week charge and discharge capacity of the full battery at 3C rate is about 170mAh / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com