A kind of lithium metal battery electrolyte containing compound additive and preparation method thereof

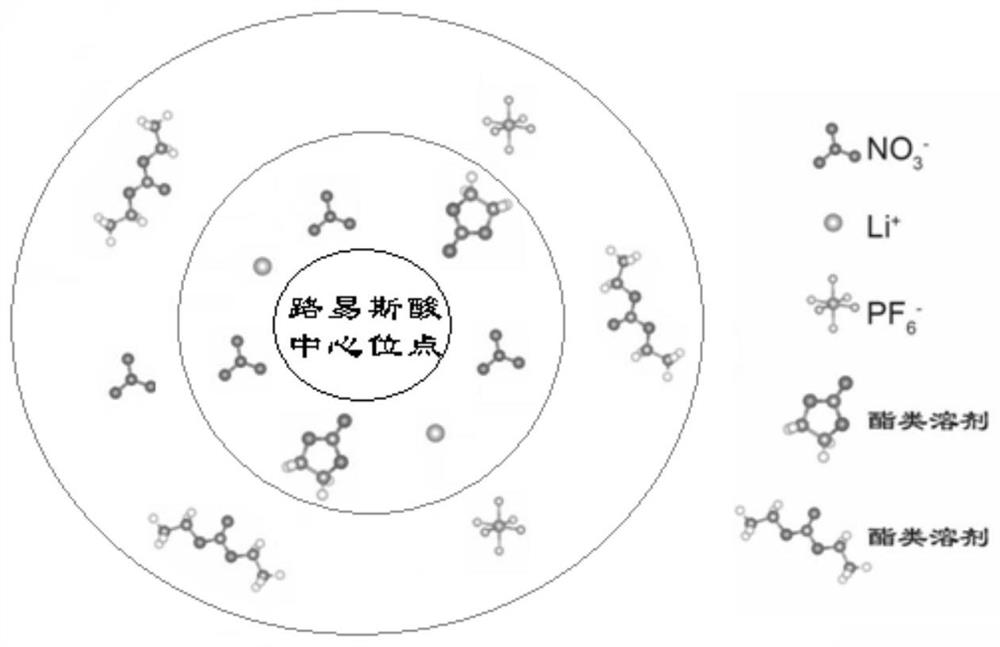

A technology of lithium metal batteries and compound additives, which is applied in lithium batteries, secondary batteries, organic electrolytes, etc., can solve problems such as low solubility of lithium nitrate, inhibit the formation of nano-scale dendritic deposition, promote grain coarsening, The effect of improving full cell performance and cycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the argon glove box, the preparation composition is ethylene carbonate:diethyl carbonate=1:1 (volume ratio), containing 1.0mol L -1 The electrolyte solution of lithium hexafluorophosphate, 0.5wt% tin trifluoromethanesulfonate and 5.0wt% lithium nitrate was heated and stirred at 40°C for 6 hours in an argon glove box until the lithium nitrate was completely dissolved.

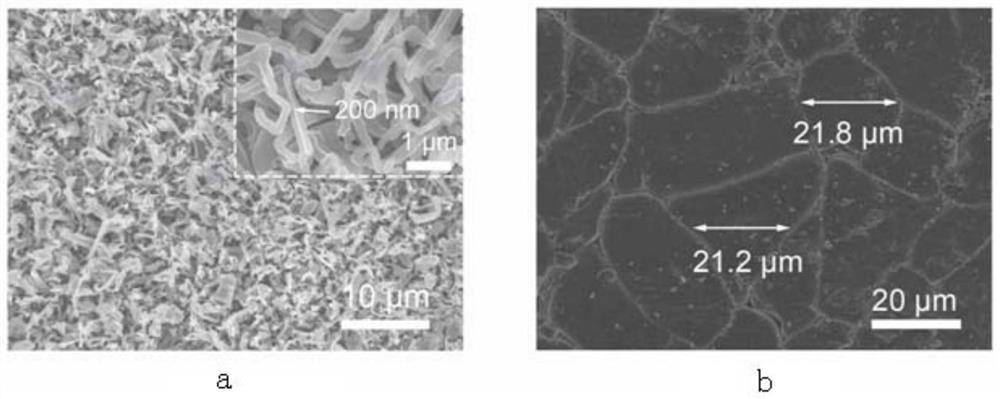

[0034] The electrolyte is used for the full battery test with metal lithium as the negative electrode and nickel-cobalt lithium manganese oxide as the positive electrode. The single-layer polypropylene film is used as the separator. After testing, the Coulombic efficiency of the negative electrode of the battery measured by the Li / Cu battery can reach 99.9. %; 530 circles of cycle life; the scanning electron microscope lithium metal deposition figure of the first circle deposition of embodiment 1 is as follows figure 2 As shown in b in , the lithium metal deposition grains are coarsened.

[0035] 45 ...

Embodiment 2

[0037] In the argon glove box, the preparation composition is fluoroethylene carbonate: diethyl carbonate = 1:2 (volume ratio), containing 1.0mol L -1The electrolyte solution of lithium hexafluorophosphate, 0.5wt% indium trifluoromethanesulfonate and 3.0wt% lithium nitrate was heated and stirred at 40°C for 4 hours in an argon glove box until the lithium nitrate was completely dissolved.

[0038] The electrolyte is used to use 45 micron thick lithium metal foil as the negative electrode and nickel-cobalt lithium manganese oxide as the positive electrode (3mAh cm -2 ) full battery test, using a single-layer polypropylene film as a diaphragm, charging and discharging at a constant current of 0.3C on a battery tester (Wuhan Landian Company), the Coulombic efficiency of the battery can reach 99.9%, and the cycle life is 320 cycles.

Embodiment 3

[0040] In the argon glove box, the preparation composition is fluoroethylene carbonate: dimethyl carbonate = 1:4 (volume ratio), containing 1.2mol L -1 The electrolyte solution of lithium hexafluorophosphate, 0.8wt% iron trifluoromethanesulfonate and 8.0wt% lithium nitrate was heated and stirred at 60°C for 6 hours in an argon glove box until the lithium nitrate was completely dissolved.

[0041] The electrolyte is used to use 45 micron thick lithium metal foil as the negative electrode and lithium iron phosphate as the positive electrode (3mAh cm -2 ) full battery test, using a single-layer polypropylene film as a diaphragm, charging and discharging at a constant current of 0.3C on a battery tester (Wuhan Landian Company), the Coulombic efficiency of the battery can reach 99.9%, and the cycle life is 1000 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com