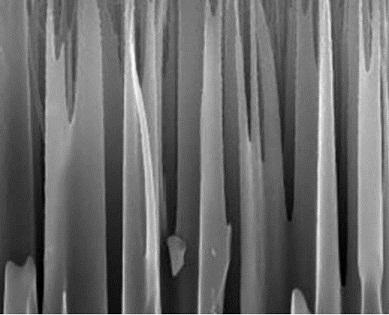

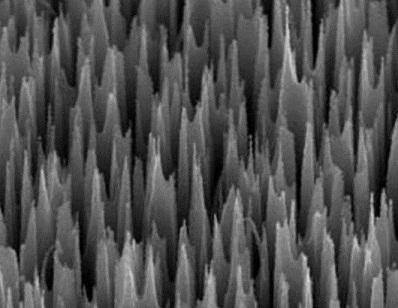

Needle-shaped alumina carrier

An alumina carrier and alumina technology, which is applied in the field of catalyst carrier preparation and gas-solid phase reaction, can solve the problems of few acupuncture alumina preparation methods and few acupuncture alumina anodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

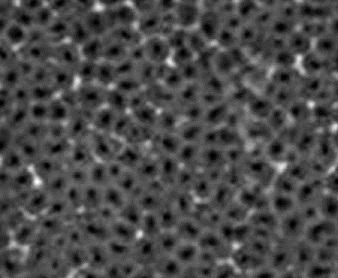

[0054] A needle-shaped alumina carrier, comprising the steps of:

[0055] (1) Pretreatment of silicon-based materials: Cut the monocrystalline silicon wafer to a suitable size, and then undergo ultrasonic cleaning with ethanol, acetone, and deionized water to remove oil stains. The number of cleanings is once, and then soak in 10wt% hydrofluoric acid for 10 minutes to remove The oxide layer was washed with deionized water and dried under an inert atmosphere;

[0056] (2) Chemical deposition of Ag particles on the silicon surface: the chemical deposition solution is an aqueous solution of silver nitrate and hydrofluoric acid, the volume ratio of AgNO3:HF:H2O is 1:2:4, and the temperature is 30 o C, the time is 1min;

[0057] (3) Ag particles catalyze the corrosion of silicon materials to obtain corrosion holes: the corrosion solution is an aqueous solution of hydrofluoric acid and hydrogen peroxide, the concentration of HF is 0.3M, and the concentration of H 2 o 2 The concen...

Embodiment 2

[0064] A needle-shaped alumina carrier, comprising the steps of:

[0065] (1) Pretreatment of silicon-based materials: Cut the monocrystalline silicon wafers to a suitable size, then undergo ultrasonic cleaning with ethanol, acetone, and deionized water to remove oil stains, repeat the cleaning times twice, and then soak in 12.5wt% hydrofluoric acid Remove the oxide layer for 10 minutes, wash with deionized water, and dry under an inert atmosphere;

[0066] (2) Chemical deposition of Ag particles on the silicon surface: the chemical deposition solution is an aqueous solution of silver nitrate and hydrofluoric acid, the volume ratio of AgNO3:HF:H2O is 1:2.5:6, and the temperature is 32.5 o C, the time is 1.5min;

[0067] (3) Ag particles catalyze the corrosion of silicon materials to obtain corrosion holes: the corrosion solution is an aqueous solution of hydrofluoric acid and hydrogen peroxide, the concentration of HF is 0.35M, and the concentration of H 2 o 2 The concentra...

Embodiment 3

[0074] A needle-shaped alumina carrier, comprising the steps of:

[0075] (1) Pretreatment of silicon-based materials: Cut the monocrystalline silicon wafers to a suitable size, then undergo ultrasonic cleaning with ethanol, acetone, and deionized water to remove oil stains, repeat the cleaning times 3 times, and then soak in 15wt% hydrofluoric acid for 10 minutes Remove the oxide layer, wash with deionized water, and dry under an inert atmosphere;

[0076] (2) Chemical deposition of Ag particles on the silicon surface: the chemical deposition solution is an aqueous solution of silver nitrate and hydrofluoric acid, the volume ratio of AgNO3:HF:H2O is 1:3:8, and the temperature is 35 o C, the time is 2min;

[0077] (3) Ag particles catalyze the corrosion of silicon materials to obtain corrosion holes: the corrosion solution is an aqueous solution of hydrofluoric acid and hydrogen peroxide, the concentration of HF is 0.45M, and the concentration of H 2 o 2 The concentration i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com