A preparation method of zirconium dioxide film with controllable crystal form and thickness

A zirconia and zirconia technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problem of long sample preparation time, and achieve short sample preparation cycle, simple experimental operation and shortening. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Cleaning the glass substrate: Put the glass substrate into a beaker, use isopropanol, deionized water, deionized water, and isopropanol to sonicate for 15 minutes in sequence, put it in an oven for drying, and then take it out.

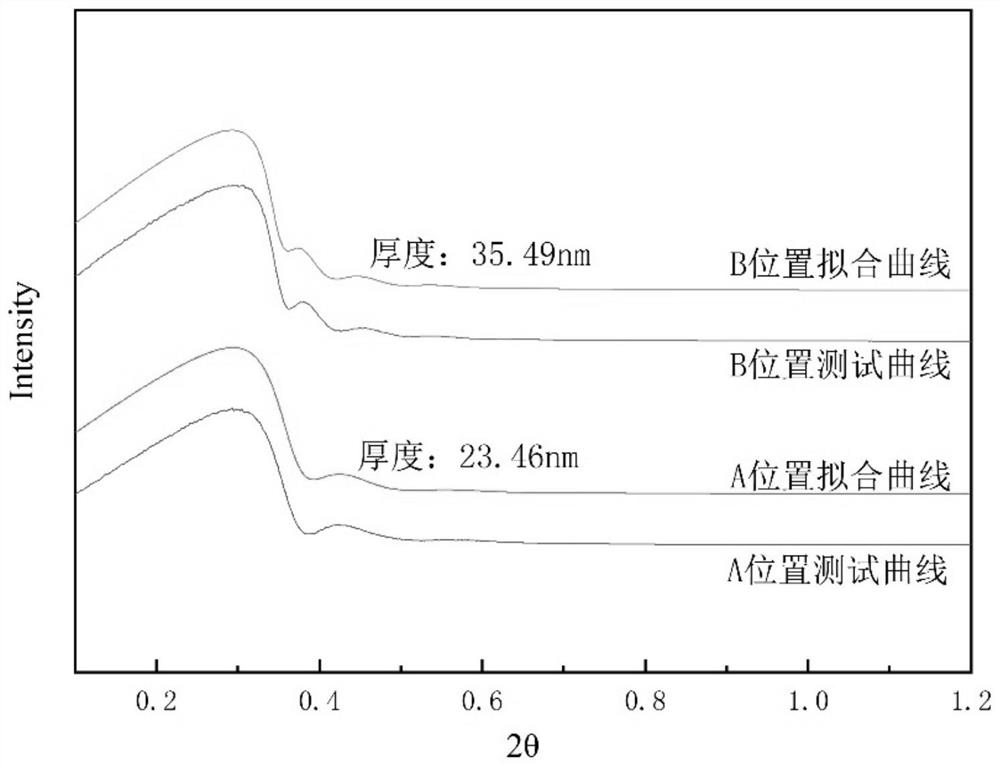

[0022] (2) Pulsed laser deposition of zirconia thin film: choose a zirconia target with a purity of 99.99%, and place a glass substrate according to figure 1 The position is fixed on the substrate and put into the vacuum chamber, and the vacuum chamber is pumped to 5×10 -4 Pa, adjust the distance between the target and the substrate to be 7cm, set the pulse frequency to 5Hz, and the laser energy to be 300mJ, and use a diamond-shaped laser spot with a vertical diagonal longer than a horizontal diagonal to irradiate the target (the shape of the laser spot and the base The placement of the chip on the substrate is as follows figure 1 shown), and after 2 minutes of pre-deposition, set the number of pulses to 27000 for deposition.

[0023] (3)...

Embodiment 2

[0027] (1) Cleaning the glass substrate: Put the glass substrate into a beaker, use isopropanol, deionized water, deionized water, and isopropanol to sonicate for 15 minutes in sequence, put it in an oven for drying, and then take it out.

[0028] (2) Pulsed laser deposition of zirconia thin film: choose a zirconia target with a purity of 99.99%, and place a glass substrate according to figure 1 The position is fixed on the substrate and put into the vacuum chamber, and the vacuum chamber is pumped to 5×10 -4 Pa, adjust the distance between the target and the substrate to 4.5cm, set the pulse frequency to 5Hz, and the laser energy to 300mJ, irradiate the target with a diamond-shaped laser spot whose vertical diagonal is longer than the horizontal diagonal, and set after 2 minutes of pre-deposition The number of pulses was 12000 for deposition.

[0029] (3) Annealing treatment: place the deposited zirconia film in an air environment for thermal annealing, the annealing tempera...

Embodiment 3

[0033] (1) Cleaning the glass substrate: Put the glass substrate into a beaker, use isopropanol, deionized water, deionized water, and isopropanol to sonicate for 15 minutes in sequence, put it in an oven for drying, and then take it out.

[0034] (2) Pulsed laser deposition of zirconia thin film: choose a zirconia target with a purity of 99.99%, and place a glass substrate according to figure 1 The position is fixed on the substrate and put into the vacuum chamber, and the vacuum chamber is pumped to 5×10 -4 Pa, adjust the distance between the target and the substrate to 5cm, set the pulse frequency to 5Hz, and the laser energy to 200mJ, use a diamond-shaped laser spot with a vertical diagonal longer than the horizontal diagonal to irradiate the target, and set the pulse after pre-deposition for 2 minutes The number is 18000 to be deposited.

[0035] (3) Annealing treatment: place the deposited zirconia film in an air environment for thermal annealing, the annealing temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com