Nanoparticles, methods of making, and applications using same

A nano-particle, reactive technology, applied in the field of nano-particles, its preparation and use, can solve the problem of phase transfer catalyst toxicity, etc., and achieve the effect of good monodispersity, short processing time and low annealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0161] Synthesis of embodiment 1.Ag nanoparticles:

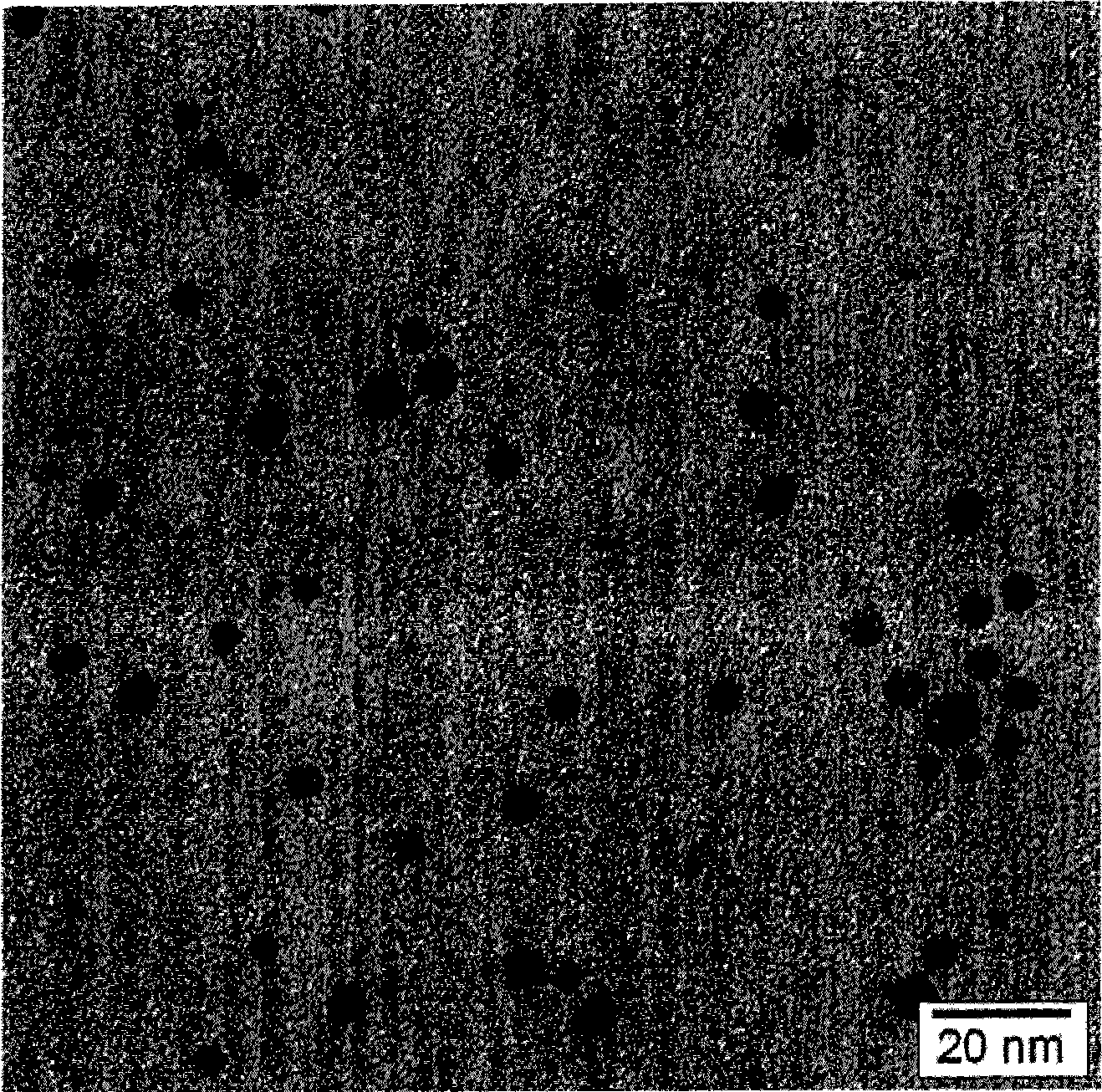

[0162] 3.34 g of silver acetate and 37.1 g of dodecylamine were dissolved in 400 ml of toluene. 1.51 g of sodium borohydride (NaBH 4 ) was dissolved in 150ml of water. NaBH was added via dropping funnel over a period of 5 minutes 4 The solution was added dropwise to the reaction flask while stirring. Stirring was continued and stopped for the 2.5 hour reaction. The solution was allowed to settle into two phases. The aqueous phase was removed through a separator funnel, followed by removal of toluene from the solution using a rotary evaporator resulting in a very thick paste. 250ml of 50 / 50 methanol / acetone was added to precipitate the Ag nanoparticles. The solution was filtered through a fine sintered glass funnel, and the solid product was collected and dried under vacuum at room temperature. 2.3 to 2.5 g of product were obtained as a dark blue solid. Nanoparticles have been detected by TEM ( figure 1 ) of 4nm to 5...

Embodiment 2

[0163] Embodiment 2. Synthesis of zinc oxide nanoparticles:

[0164] 6.3 grams of zinc stearate [Zn(C 18 h 35 o 2 ) 2 ] and 10 grams of cetylamine were dissolved in 400ml of toluene. 1.2 grams of potassium hydroxide (KOH) was dissolved in 150 ml of water. The KOH solution was added dropwise to the reaction flask via the dropping funnel over a period of 5 minutes while stirring. Stirring was continued and stopped for the 2 hour reaction. The aqueous phase was removed through a separator funnel, followed by a rotary evaporator to remove toluene from the solution. 250ml of 50 / 50 methanol / acetone was added to precipitate the zinc oxide nanoparticles. The solution was filtered through a fine sintered glass funnel, and the solid product was collected and dried under vacuum at room temperature. About 0.8 g of white solid product was obtained. Nanoparticles have been detected by TEM( Image 6 ) detected size of about 7.4nm (with a small number of ZnO nanoneedles present).

Embodiment 3

[0165] Example 3. Coated conductive films from sintered silver nanoparticles:

[0166] A cyclohexane solution with a content of 10% to 20% by weight of the Ag nanoparticles synthesized in Example 1 was prepared, and it was spin-coated on a clean glass substrate at about 1500 rpm to produce a thickness of 0.1 Micron to 0.3 micron nanoparticle coated film. The nanoparticle film was heated to a temperature in the range of 90°C to 180°C for 10 minutes, while the color of the film changed from dark brown to bright silver. The conductivity of the sintered silver films was measured by a four-point probe instrument. The results are listed in Table 2. It demonstrates that films sintered at sintering temperatures above 150° C. have excellent electrical conductivity, which reaches about 70% of pure silver.

[0167] Table 2

[0168] Annealing temperature (℃) Resistivity (ohm-cm) 90

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com