Modified slurry for carbon-carbon brake disc and preparation method of carbon-carbon brake disc

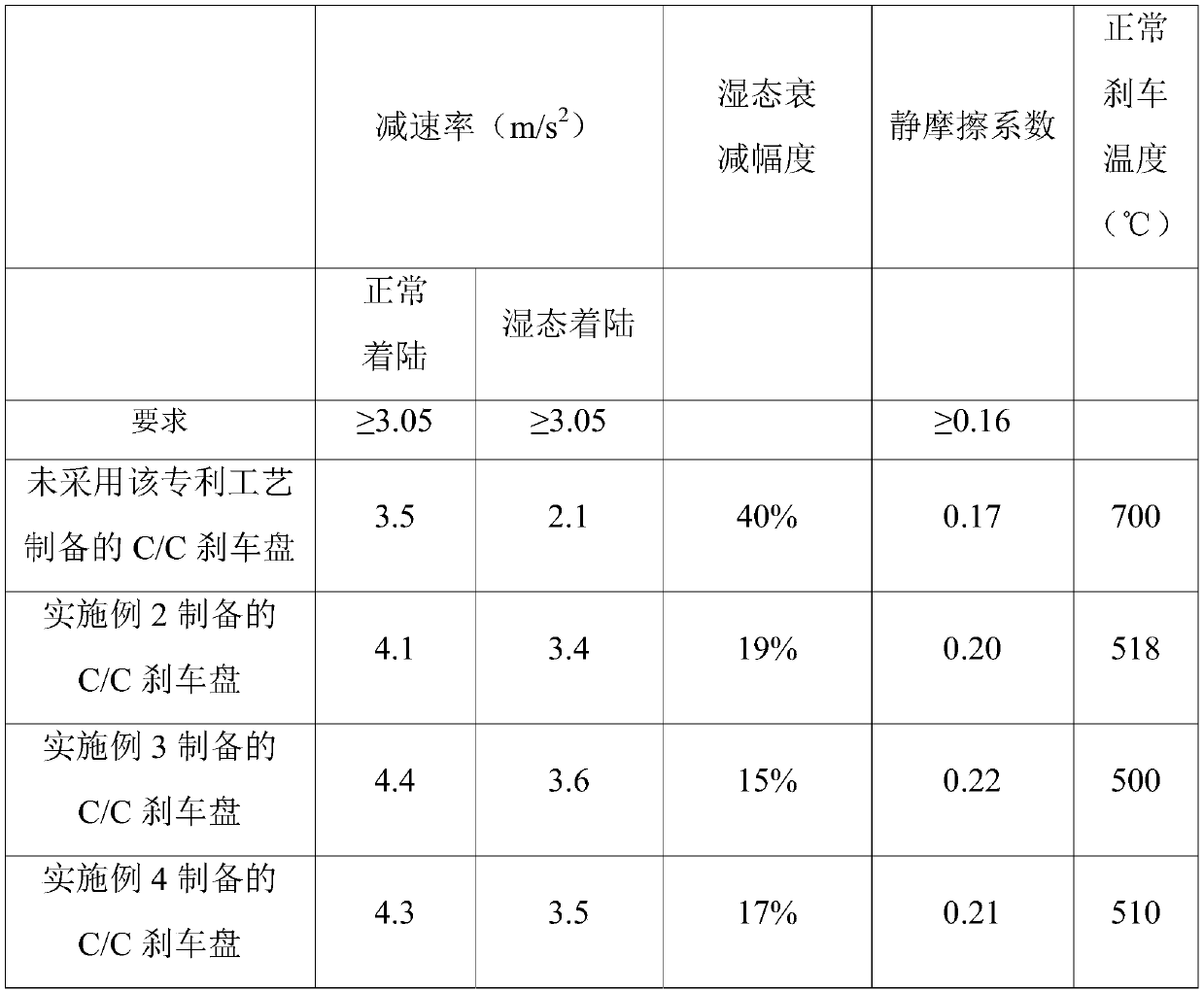

A technology of carbon-carbon brake discs and modified slurry, which is applied in the field of preparation of carbon-carbon brake disc modified slurry and carbon-carbon brake discs, can solve high braking temperature, poor wet braking performance, and static friction of carbon-carbon brake discs Low coefficient and other problems, to achieve the effect of reducing brake temperature, improving wet friction performance, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A carbon-carbon brake disc modified slurry, including a modifier with a mass percentage of 7-10%, a suspension agent with a mass percentage of 1-2%, and a mixture of deionized water with a mass percentage of 80-90% be made of. The suspending agent is sodium carboxymethylcellulose. The modifier includes graphite powder with a mass percentage of 10-15%, and B with a mass percentage of 20-35%. 4 C powder, silicon carbide powder with a mass percentage of 25-35% and carbon powder with a mass percentage of 30-40%. The graphite powder, B 4 The particle diameters of C powder, silicon carbide powder and carbon powder are all 1-5 μm.

Embodiment 2

[0022] Embodiment 2: a kind of preparation method of carbon-carbon brake disk, comprises the following steps:

[0023] 1) slurry preparation step, the graphite powder that is 11% by mass percentage, the B that mass percentage is 30% 4 C powder, silicon carbide powder with a mass percentage of 26% and carbon powder with a mass percentage of 33% are mixed to obtain a modifier; the modifier is added to deionized water to form a modified slurry, and carboxymethyl cellulose is added Sodium is used as slurry suspending agent; Wherein, the mass percentage of modifying agent is 8.9%, the mass percentage of suspending agent is 1.7%, and the mass percentage of deionized water is 89.4%;

[0024] 2) Perform the impregnation step on the brake disc prefabricated body, mix the modified slurry obtained in step 1) with furan resin or phenolic resin according to the ratio of 23% by mass: 77% to prepare an impregnant; then use vacuum pressure The impregnating agent is impregnated into the C / C b...

Embodiment 3

[0028] Embodiment 3: a kind of preparation method of carbon-carbon brake disk, comprises the following steps:

[0029] 1) slurry preparation step, the graphite powder that mass percentage is 13%, the B that mass percentage is 28% 4 C powder, silicon carbide powder with a mass percentage of 27% and carbon powder with a mass percentage of 32% are mixed to obtain a modifier; the modifier is added to deionized water to form a modified slurry, and carboxymethyl cellulose is added Sodium is used as slurry suspending agent; Wherein, the mass percentage of modifying agent is 9.5%, the mass percentage of suspending agent is 1.5%, and the mass percentage of deionized water is 89%;

[0030] 2) Impregnating the brake disc prefabricated body, mixing the modified slurry obtained in step 1) with the furan resin according to the ratio of 25% by mass: 75% to prepare an impregnating agent; then using a vacuum pressure process to impregnate The agent is impregnated into the C / C brake disc prefa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com