almgb 14 Preparation method of ceramic material powder

An almgb14 and ceramic powder technology, which is applied in the field of preparation of AlMgB14 ceramic material powder, can solve the problems of increased preparation cost, complicated preparation process and high equipment requirements, and achieves the effects of low cost, simple process and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

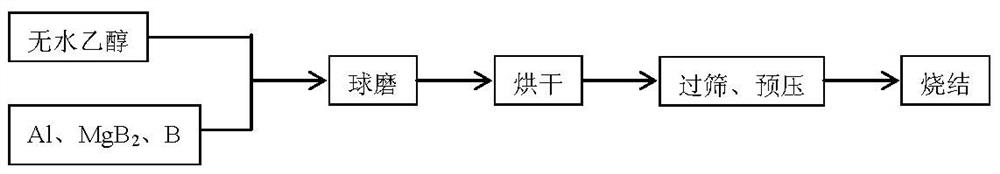

[0028] The present invention relates to a kind of AlMgB 14 The preparation method of ceramic material powder adopts absolute ethanol as solvent, will comprise the Al powder that mass ratio is 1:(1.2~1.4):(3.6~4.2) Al powder, MgB 2 Boron powder and boron powder raw material powders are ball milled and mixed, dried after mixing evenly, pre-pressed into blocks and placed in a sintering furnace (such as a vacuum sintering furnace, etc.) for high temperature reaction ( figure 1 ). The present invention uses absolute ethanol as the ball milling medium to shorten the ball milling time and reduce the types and contents of metal oxide impurities, and use MgB 2 Instead of metal Mg, the risk of experiment is reduced, and mass production can be realized. The preparation process of the method of the present invention is simple, and it is easier to realize batch production, which greatly reduces the production cost.

[0029] As raw material powder, including Al powder, MgB 2 powder and ...

Embodiment 1

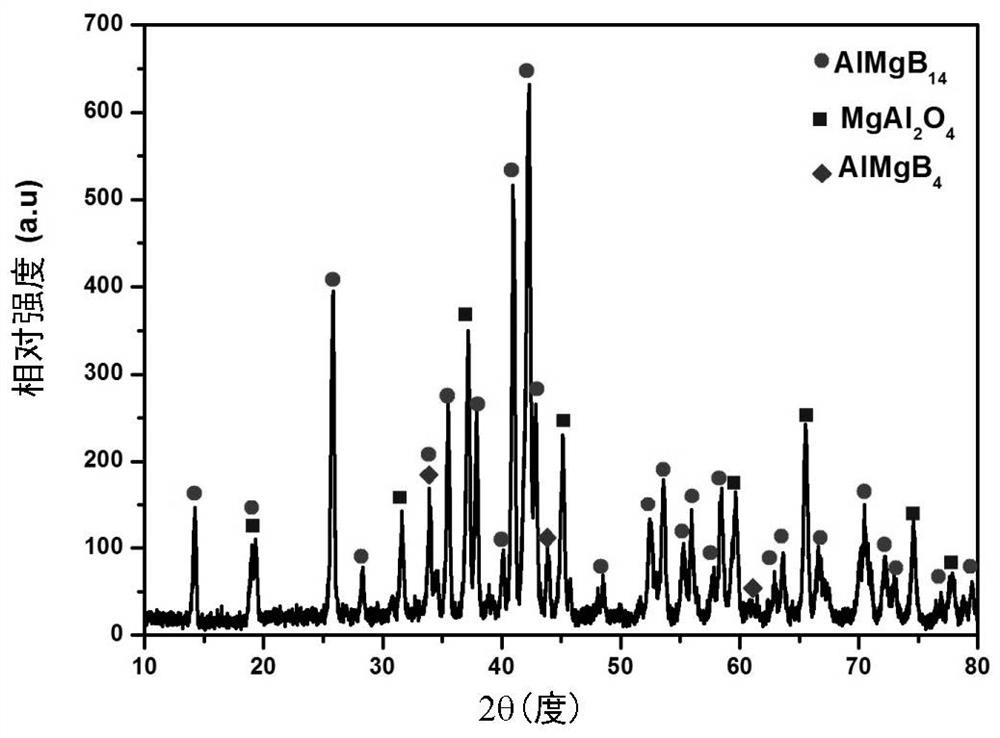

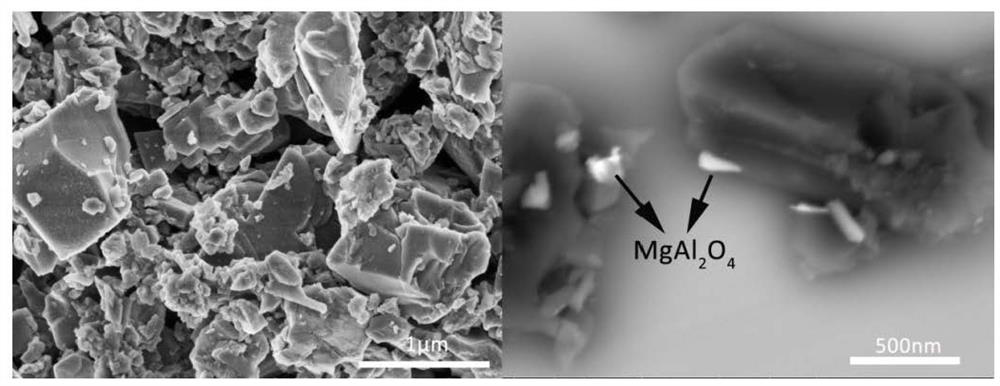

[0046] Weigh Al powder (purity 99.9%, particle size 1 μm), MgB according to mass ratio 1:1.2:3.6 2 Powder (purity is 99.9%, particle size is 5 μm), amorphous B powder (purity is 99.9%, particle size is 1 μm), according to (mass ratio) raw material powder: absolute ethanol (analytical pure): grinding ball mass ratio is 5:10:13 and dispersant PVP (3wt%), ball milled in a ball mill at a speed of 380r / min for 1h. After the slurry is dried, it is dry-pressed at 20MPa, and the holding time is 30s. Put it in a vacuum sintering furnace and heat it. The sintering system is as follows: (i) keep at 400°C for 1h, the heating rate is 10°C / min, and the vacuum degree is 0.05Pa; (ii) keep at 1200°C for 4h for reaction sintering, and the heating rate is 10°C / min. The protective atmosphere for sintering is high-purity argon atmosphere. Thus, the AlMgB 14 Powder.

Embodiment 2

[0048] Weigh Al powder and MgB according to the mass ratio of 1:1.2:4 2 Powder, amorphous B powder, according to (mass ratio) raw material powder: anhydrous ethanol: ball mass ratio of 5:10:13 and dispersant PVP (4wt%), ball milled in a ball mill at a speed of 380r / min for 1h. After the slurry is dried, it is dry-pressed at 20MPa, and the holding time is 30s. Put it in a vacuum sintering furnace and heat it. The sintering system is as follows: (i) heat preservation at 600°C for 1h, heating rate 10°C / min, vacuum degree 0.05Pa; (ii) reaction sintering at 1250°C for 3h, heating rate 10°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com