Method for improving ohm of p-type gallium nitride

A technology of gallium nitride and gallium nitride layer, which is applied in the field of semiconductor material growth and device preparation, can solve the problems of difficult to achieve high-quality p-type gallium nitride ohmic contact and low hole concentration, achieve low ohmic contact, simplify Process, the effect of realizing ohmic contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

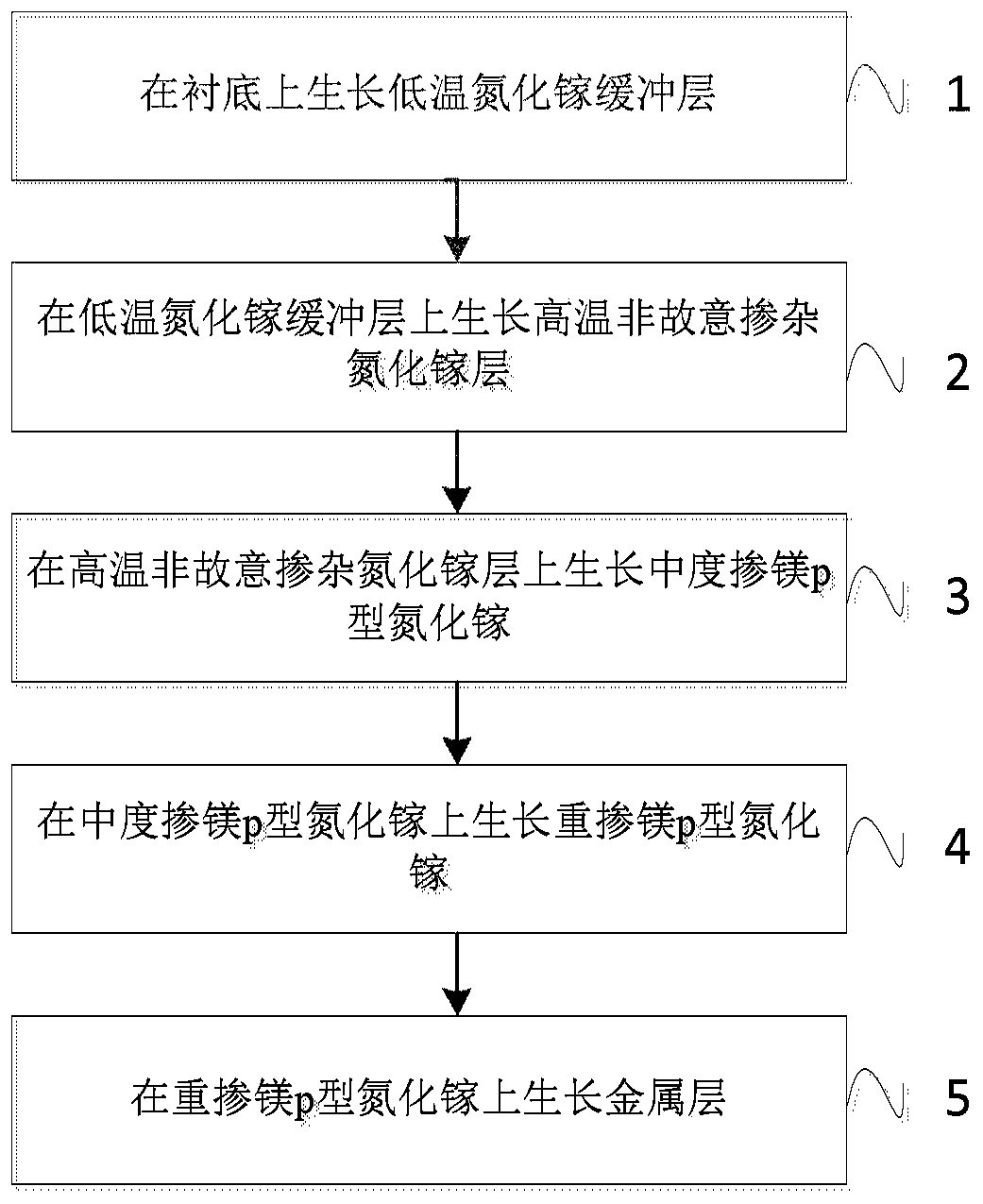

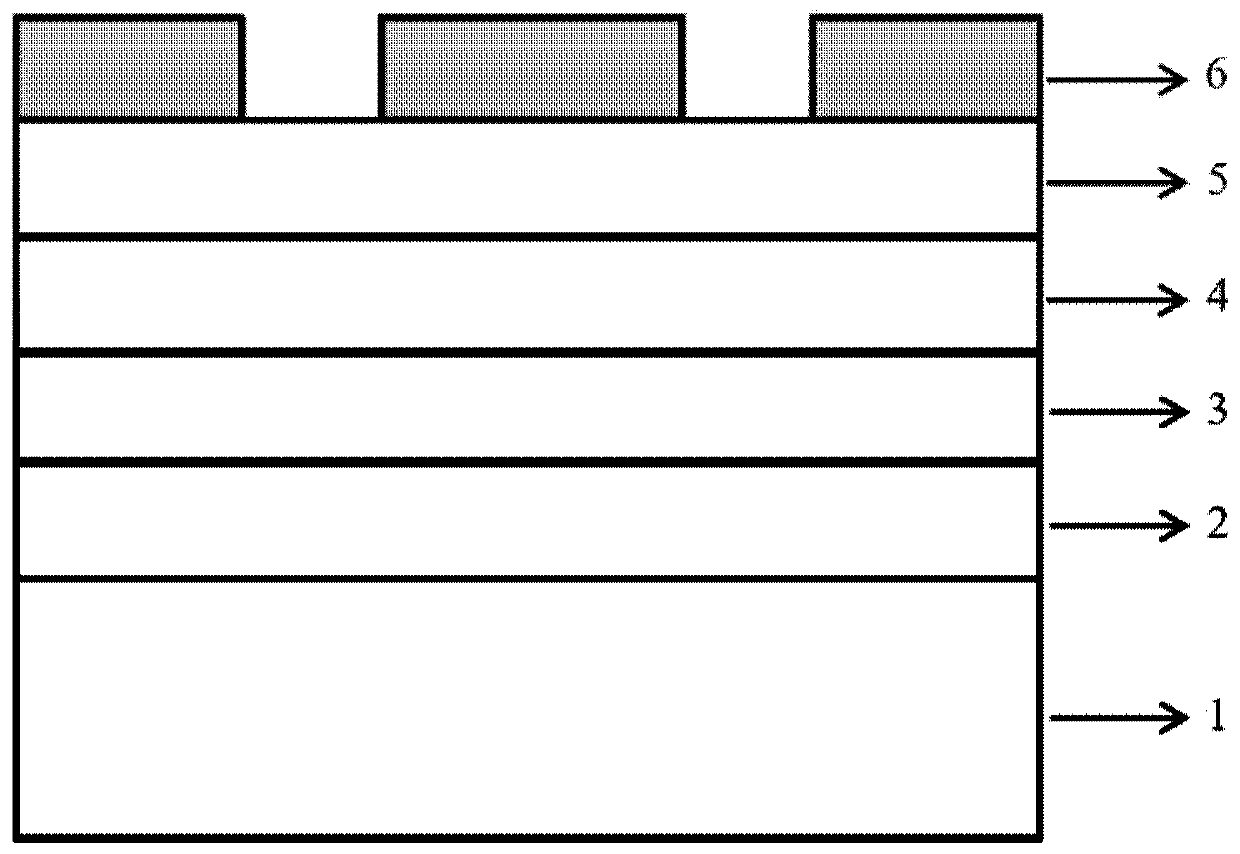

[0048] Step S1: Infuse ammonia gas, and turn on the gallium source. A 50nm low-temperature gallium nitride buffer layer 2 is grown on a sapphire substrate 1 by metalorganic chemical vapor deposition method, and the growth temperature is 550°C.

[0049] Step S2: growing a high-temperature unintentionally doped gallium nitride layer 3 of 1000 nm on the low-temperature gallium nitride buffer layer 2 by using metalorganic chemical vapor deposition, and the growth temperature is 1100° C.

[0050] Step S3: growing a moderately magnesium-doped p-type gallium nitride layer 4 on the unintentionally doped gallium nitride layer, the thickness of which is 500 nm, wherein the concentration of magnesium acceptor impurities is about 1×10 19 em -3 .

[0051] Step S4: grow a heavily magnesium-doped p-type gallium nitride layer 5 with a thickness of about 20 nm on the moderately magnesium-doped p-type gallium nitride layer 4, and control the carbon impurity concentration of the layer by adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com