A preparation method of SIC based ohmic contacts with ultra-high heat dissipation performance

A technology of heat dissipation performance and ohmic contact, which is applied in the field of SiC-based ohmic contact preparation, can solve the problem of sacrificing specific contact resistivity, achieve good high-temperature electrical performance, and reduce the effect of specific contact resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

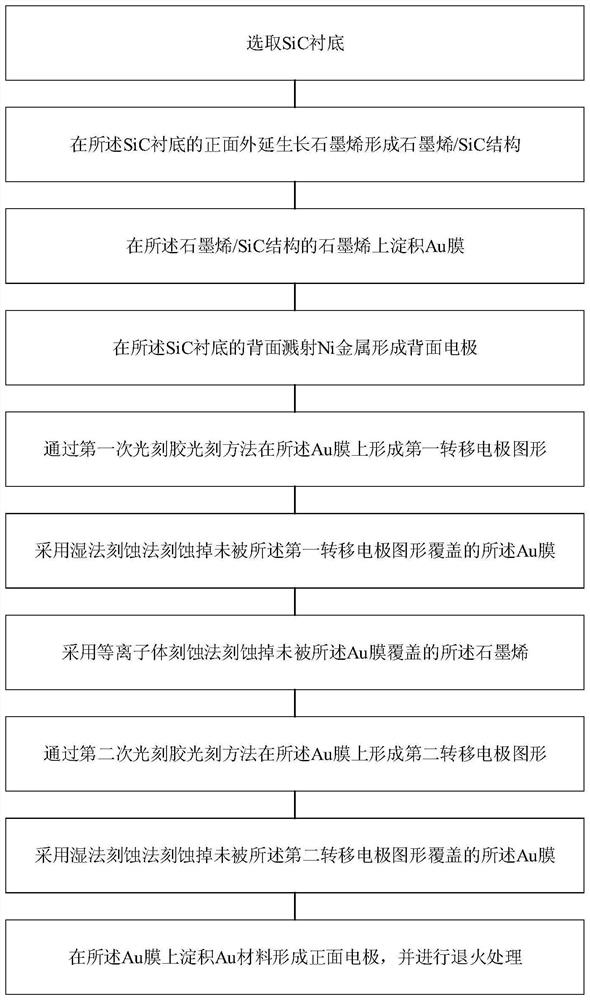

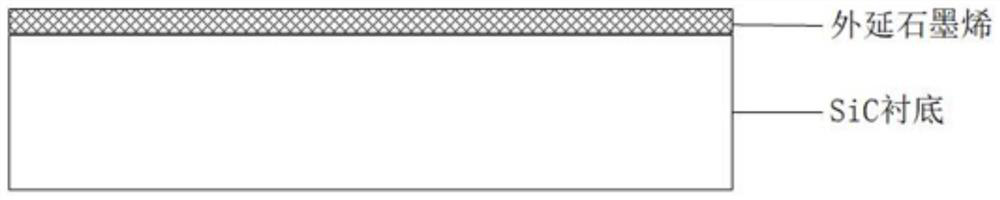

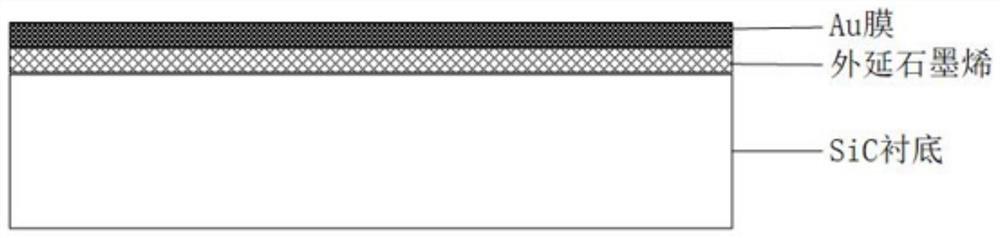

[0046] In order to achieve the purpose of improving the heat dissipation performance and high temperature stability of the ohmic contact structure without sacrificing the specific contact resistivity as much as possible, please refer to figure 1 , Figure 2a ~ Figure 2h , figure 1 It is a schematic flow chart of a method for preparing a SiC-based ohmic contact with ultra-high heat dissipation performance provided by an embodiment of the present invention, Figure 2a ~ Figure 2h It is a schematic structural diagram of a method for preparing a SiC-based ohmic contact with ultra-high heat dissipation performance provided by an embodiment of the present invention. This embodiment provides a method for preparing a SiC-based ohmic contact with ultra-high heat dissipation performance. The method for preparing a SiC-based ohmic contact with ultra-high heat dissipation performance includes the following steps:

[0047] Step 1. Select a SiC substrate.

[0048] Specifically, the SiC s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com