High-power laser wave front measuring instrument and wave front measuring method

A laser wave and measuring instrument technology, applied in the field of laser technology measurement, can solve problems such as the inapplicability of wavefront analyzers, and achieve the effects of fast detection speed, clear and simple operation, and effective attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The measurement principle, system structure and specific working process of the present invention will be described in detail and completely below in conjunction with the accompanying drawings.

[0029] 1, system structure of the present invention and concrete work process are as follows:

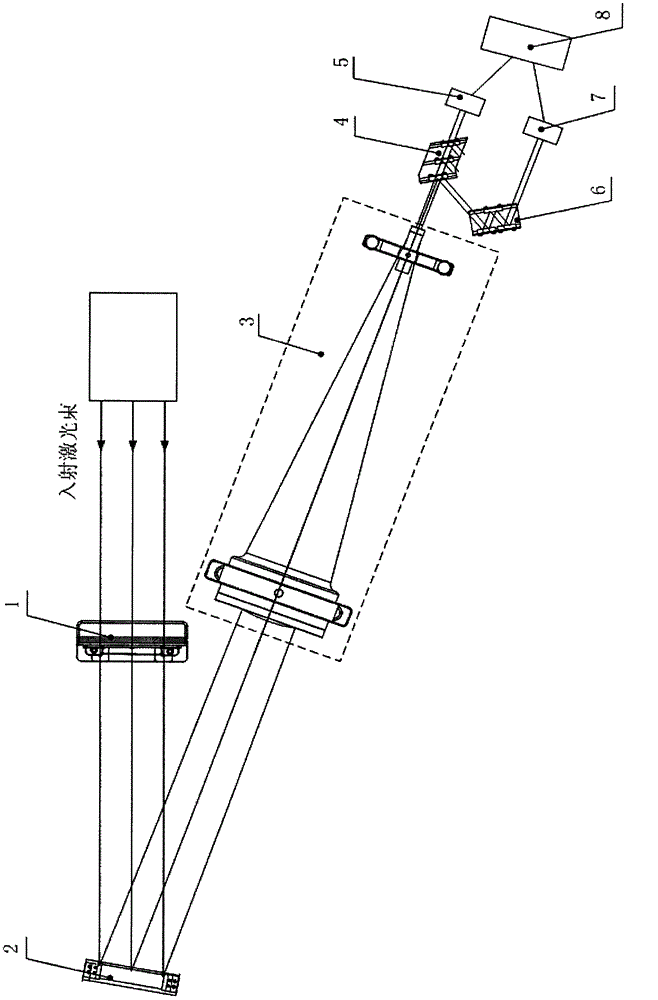

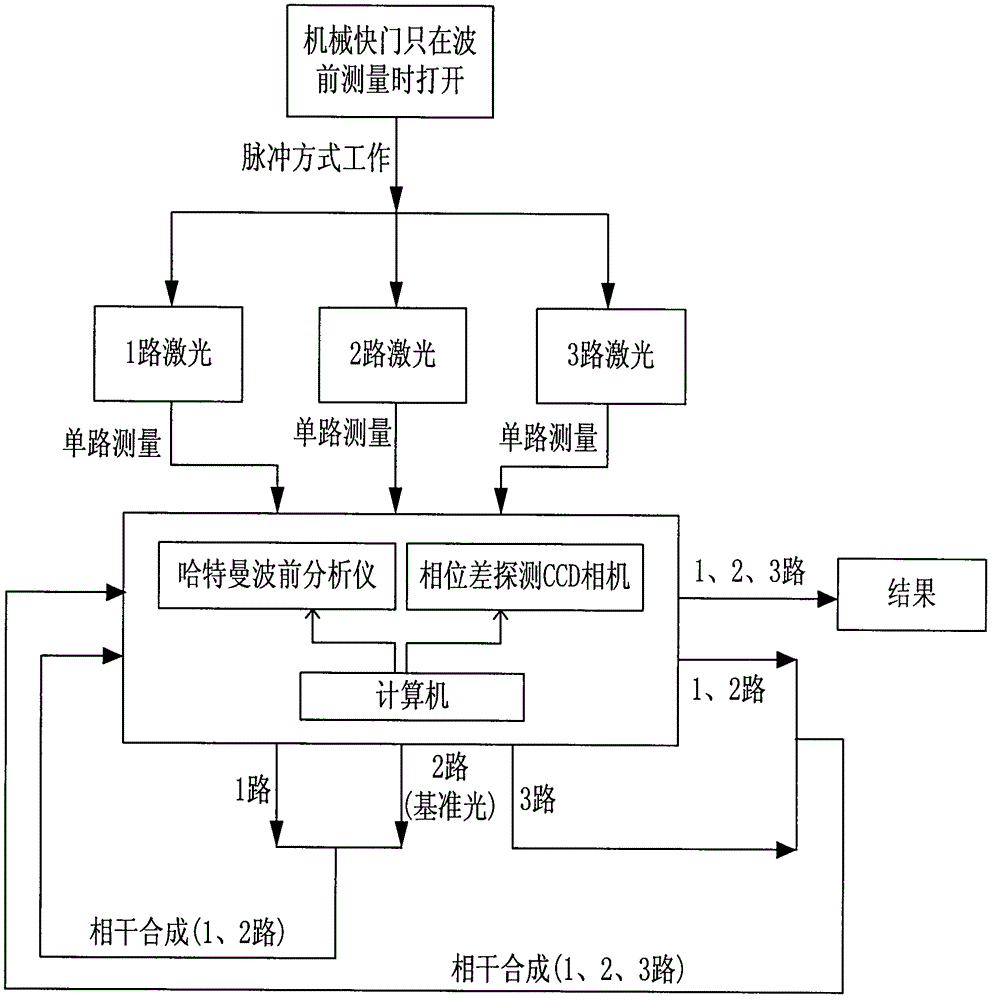

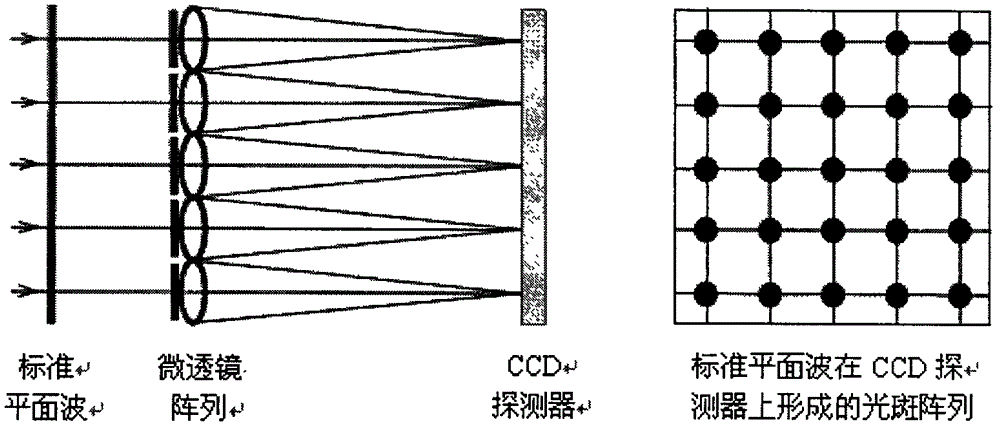

[0030] refer to figure 1 , the measuring instrument of the present invention comprises: mechanical shutter 1, beam sampling mirror 2, beam reduction optical system 3, transmission attenuator 4, reflection attenuator 6, Hartmann wavefront analyzer 5, phase difference detection CCD camera 7 and computer 8. The mechanical shutter 1 is only opened during the wavefront measurement, so that the measuring instrument works in a pulse mode, so as to avoid thermal deformation of the optical components of the measurement system caused by high-power laser and affect the measurement accuracy. The beam sampling mirror 2 attenuates the high-power laser for the first time, and reflects the laser b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com