Module-integrated instant-heating electric boiler main machine and manufacturing process thereof

A manufacturing process and electric boiler technology, applied in the direction of steam boilers, steam boiler accessories, steam boiler components, etc., can solve public electric shock casualties, immeasurable harm, electrification of residents' homes and public heating facilities, etc., to achieve Effect of high practical value, light weight, unique novelty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

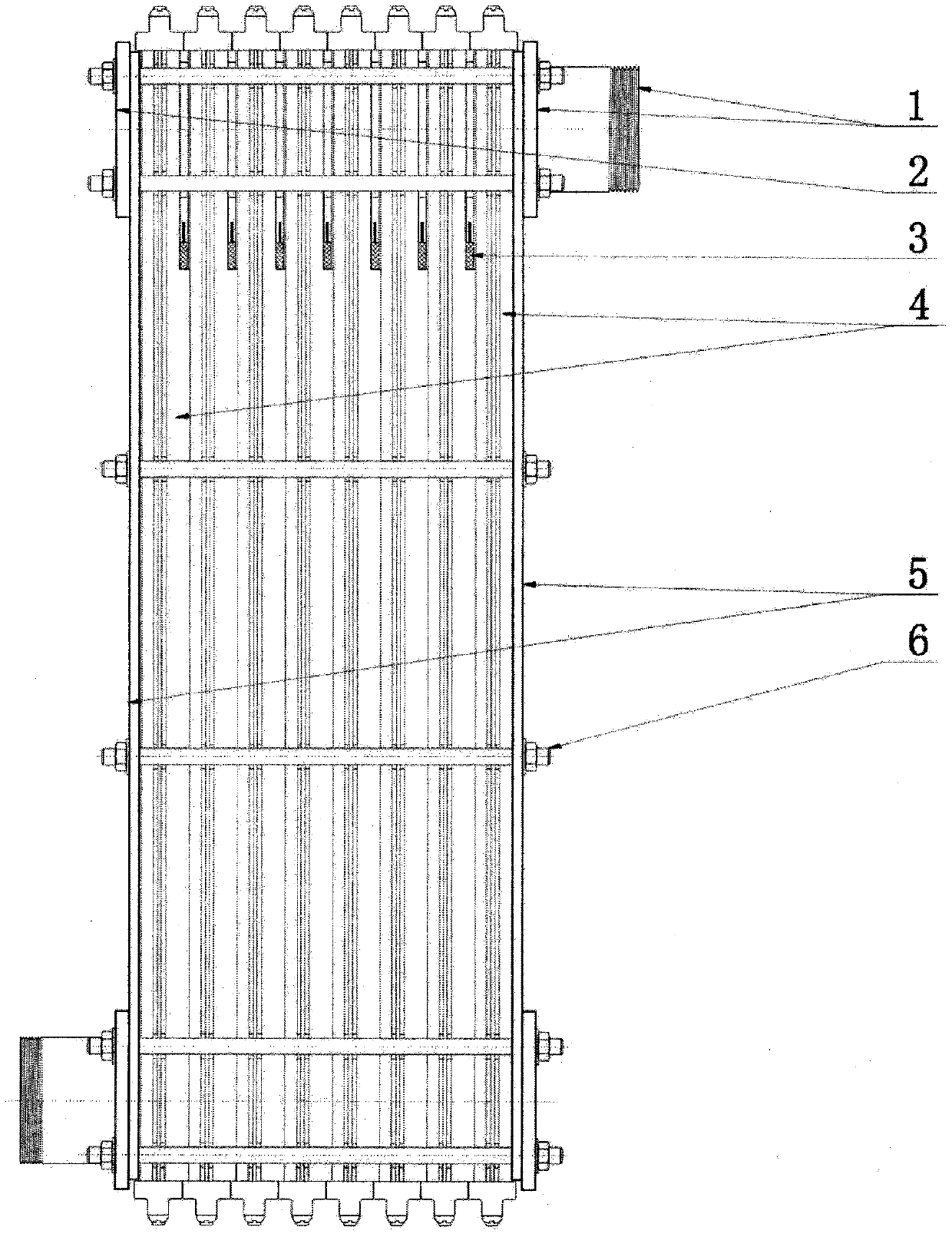

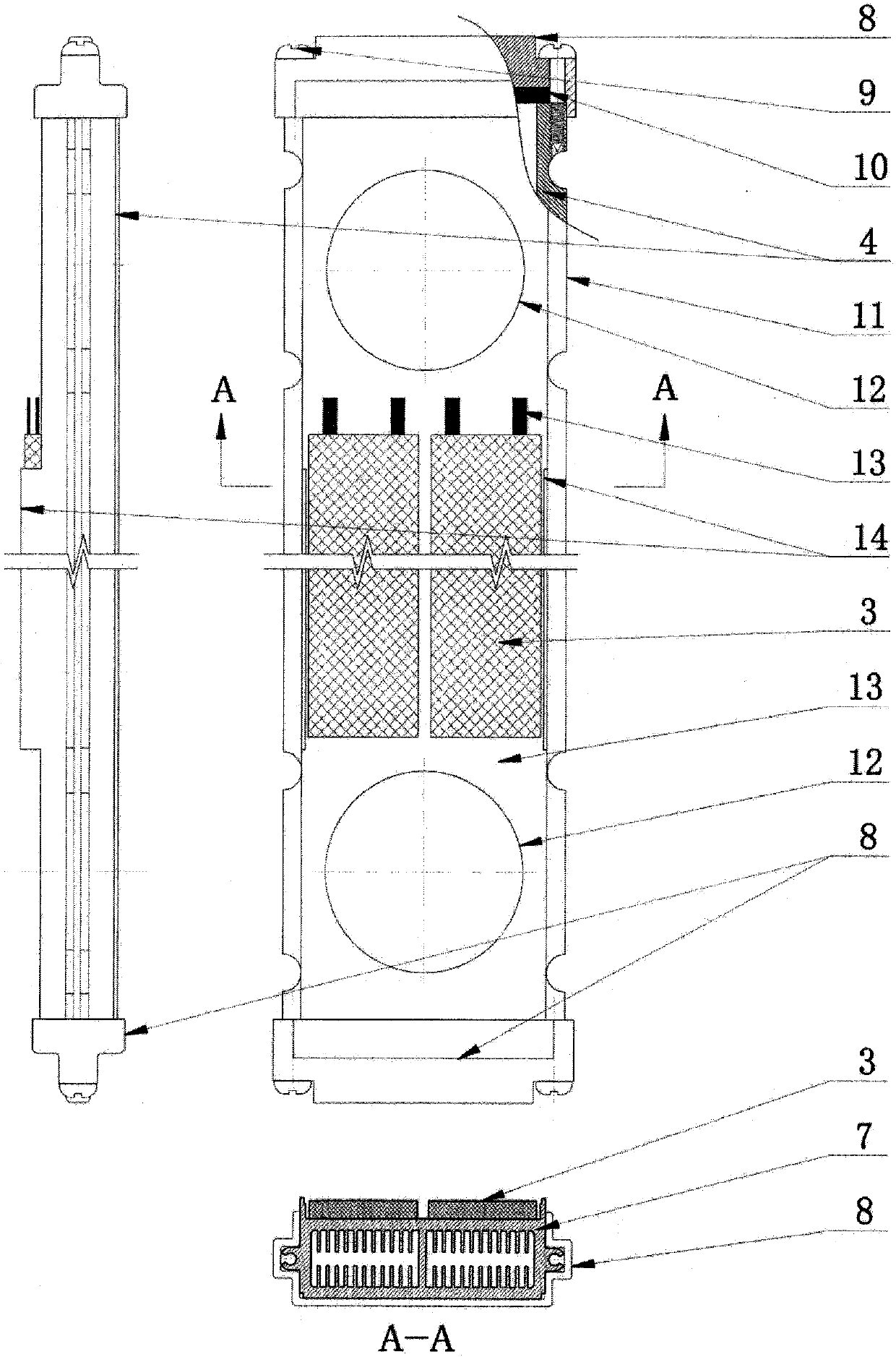

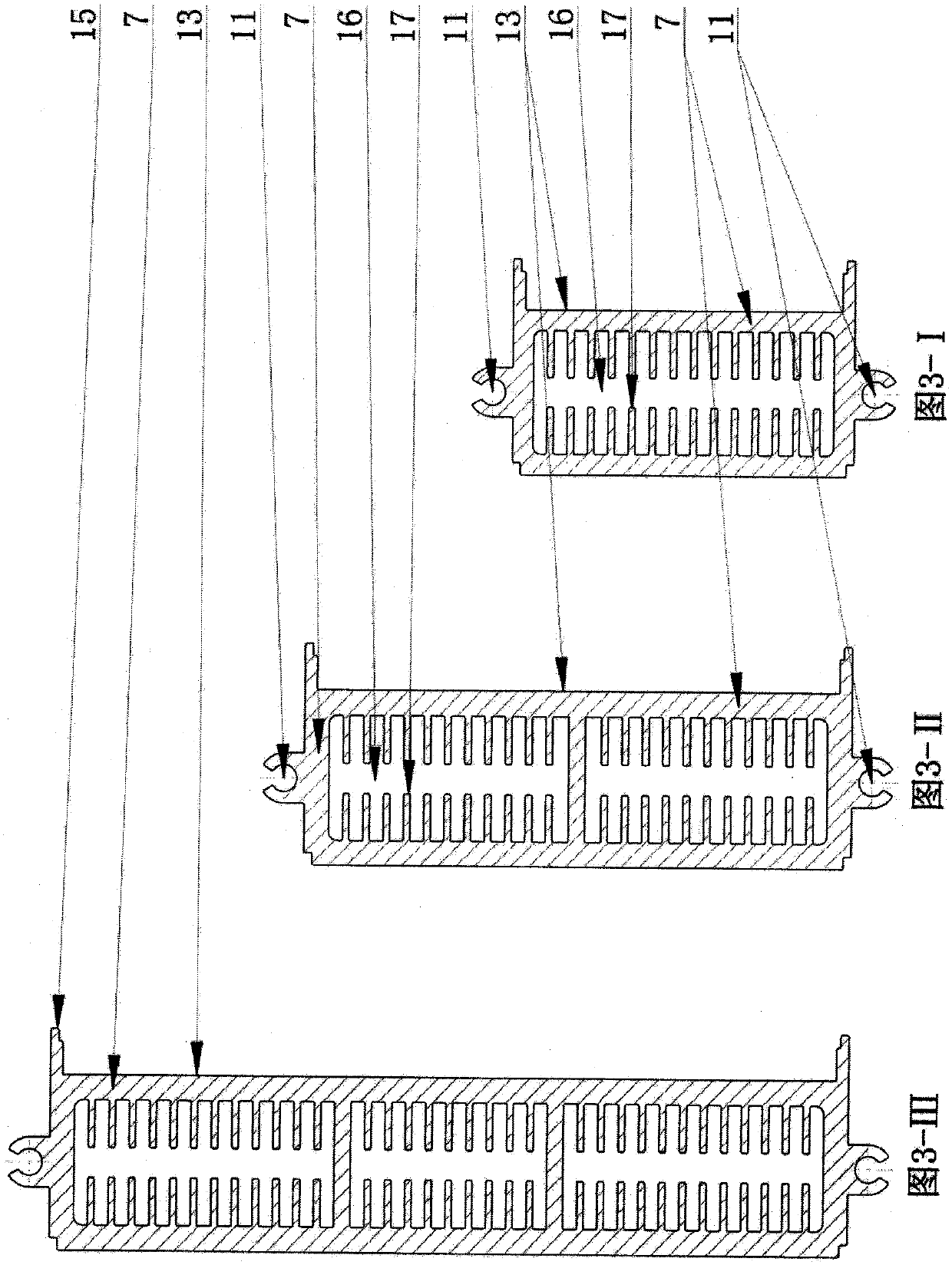

[0016] see Figure 1 to Figure 6 , the present invention's module-integrated fast-heating electric boiler host and its manufacturing process, the module-integrated fast-heating electric boiler host is composed of a sheet heater (3), a profile module (4), an inlet and outlet water assembly, and a clamping assembly; (5), profile module (4) two ends open runner hole (12), the profile groove plane (13) installs sheet heater (3) in profile module (4) middle section, in sheet heater (3) ) on top of which another layer of profile module (4) and sheet heater (3) are stacked, and stacked in sequence to 2 to 100 layers and the required number of layers; a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com