Corrosive agent for displaying metallographic structure of cobalt chromium molybdenum alloy and corrosion method

A technology of cobalt-chromium-molybdenum alloy and metallographic structure is applied in the field of metallographic corrosion, which can solve the problems of poor corrosion effect, inability to display metallographic grain boundaries clearly, and long corrosion time, so as to improve the corrosion effect, not easily cause damage, The effect of reducing the corrosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

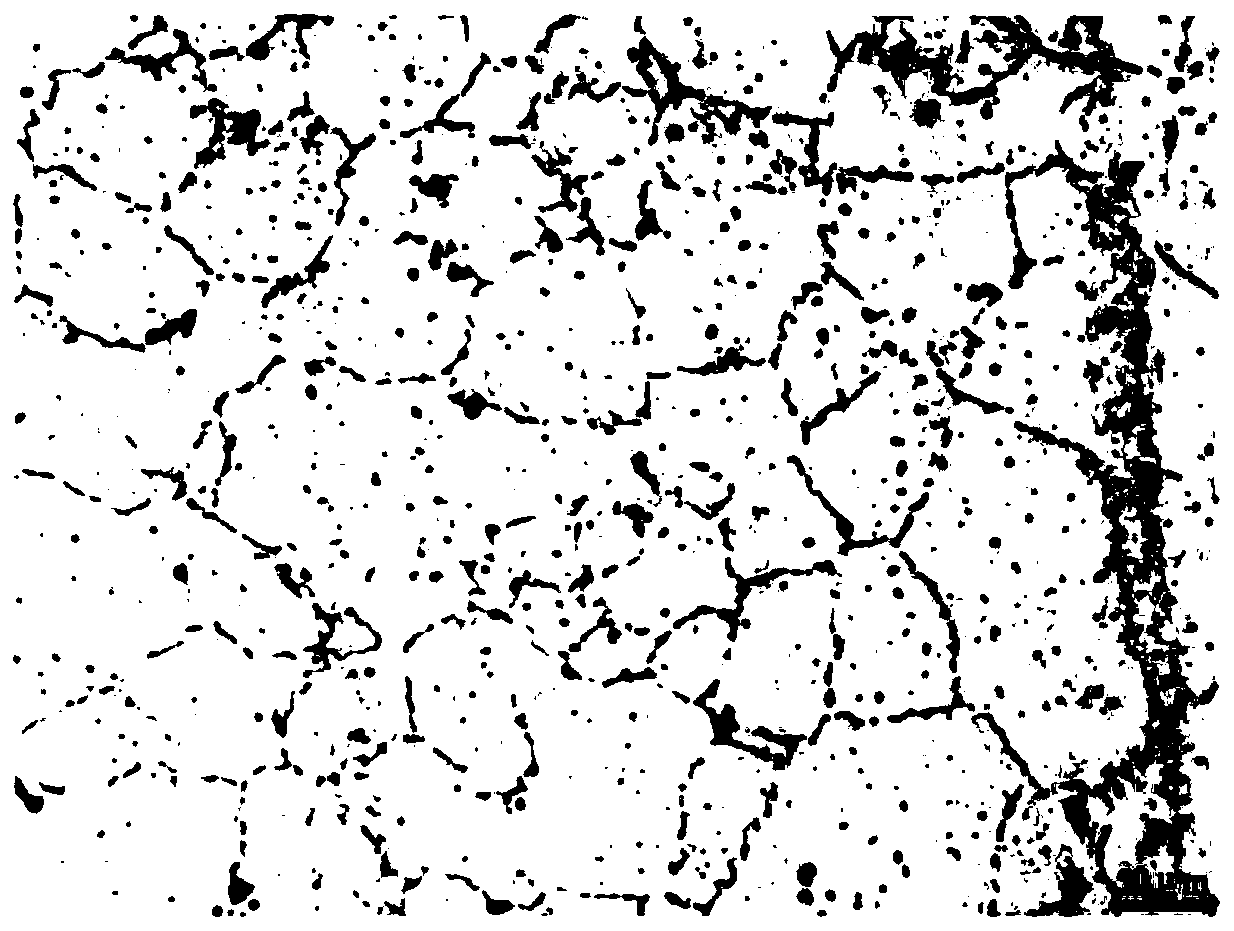

Image

Examples

Embodiment 1

[0068] In this embodiment, the formula of the corrosive agent is: 8 g of sodium hydroxide, 8 g of potassium permanganate, and 200 ml of pure water.

[0069] The cobalt-chromium-molybdenum alloy material in this embodiment is a certain brand of powder metallurgy sintered cobalt-chromium-molybdenum alloy, and the weight percentage of each component is Cr: 26%-30%, Mo: 5-7%, C: ≤1% , Co: balance.

[0070] The corrosion method used to reveal the metallographic structure of cobalt-chromium-molybdenum alloys includes the following steps:

[0071] (1) Metallographic production: wire-cut the cobalt-chromium-molybdenum alloy material to make a metallographic sample of 25mm×25mm×6mm. Select acrylic powder to cold-mount metallographic samples; use metallographic water sandpaper of different particle sizes (400 mesh, 800 mesh, 1000 mesh, 1200 mesh, 1500 mesh, 2000 mesh) to carry out water grinding on a metallographic grinder, and use sandpaper of the same mesh number for water grinding. ...

Embodiment 2

[0074] In this embodiment, the formula of the corrosive agent is: 4 g of potassium hydroxide, 7 g of potassium permanganate, and 150 ml of pure water.

[0075] The cobalt-chromium-molybdenum alloy material in this embodiment is a certain brand of powder metallurgy sintered cobalt-chromium-molybdenum alloy, and the weight percentage of each component is Cr: 26%-30%, Mo: 5-7%, C: ≤1% , Co: balance.

[0076] The corrosion method used to reveal the metallographic structure of cobalt-chromium-molybdenum alloys includes the following steps:

[0077] (1) Metallographic production: wire-cut the cobalt-chromium-molybdenum alloy material to make a metallographic sample of 25mm×25mm×6mm. Select acrylic powder to cold-mount metallographic samples; use metallographic water sandpaper of different particle sizes (400 mesh, 800 mesh, 1000 mesh, 1200 mesh, 1500 mesh, 2000 mesh) to carry out water grinding on a metallographic grinder, and use sandpaper of the same mesh number for water grindin...

Embodiment 3

[0080] In this embodiment, the formula of the corrosive agent is: 5 g of sodium hydroxide, 4 g of potassium permanganate, and 100 ml of pure water.

[0081] The cobalt-chromium-molybdenum alloy material in this embodiment is a certain brand of powder metallurgy sintered cobalt-chromium-molybdenum alloy, and the weight percentage of each component is Cr: 26%-30%, Mo: 5-7%, C: ≤1% , Co: balance.

[0082] The corrosion method used to reveal the metallographic structure of cobalt-chromium-molybdenum alloys includes the following steps:

[0083] (1) Metallographic production: wire-cut the cobalt-chromium-molybdenum alloy material to make a metallographic sample of 25mm×25mm×6mm. Select acrylic powder to cold-mount metallographic samples; use metallographic water sandpaper of different particle sizes (400 mesh, 800 mesh, 1000 mesh, 1200 mesh, 1500 mesh, 2000 mesh) to carry out water grinding on a metallographic grinder, and use sandpaper of the same mesh number for water grinding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com