Ultra-low carbon steel metallographic corrosive agent and display method of metallographic structure

A technology of ultra-low carbon steel and corrosive agent, which is applied in the preparation of test samples, measuring devices, and material analysis by optical means, etc., can solve the problems of difficult corrosion, high production cost, poor operation controllability, etc. Simple, easy to operate, and the effect of short corrosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

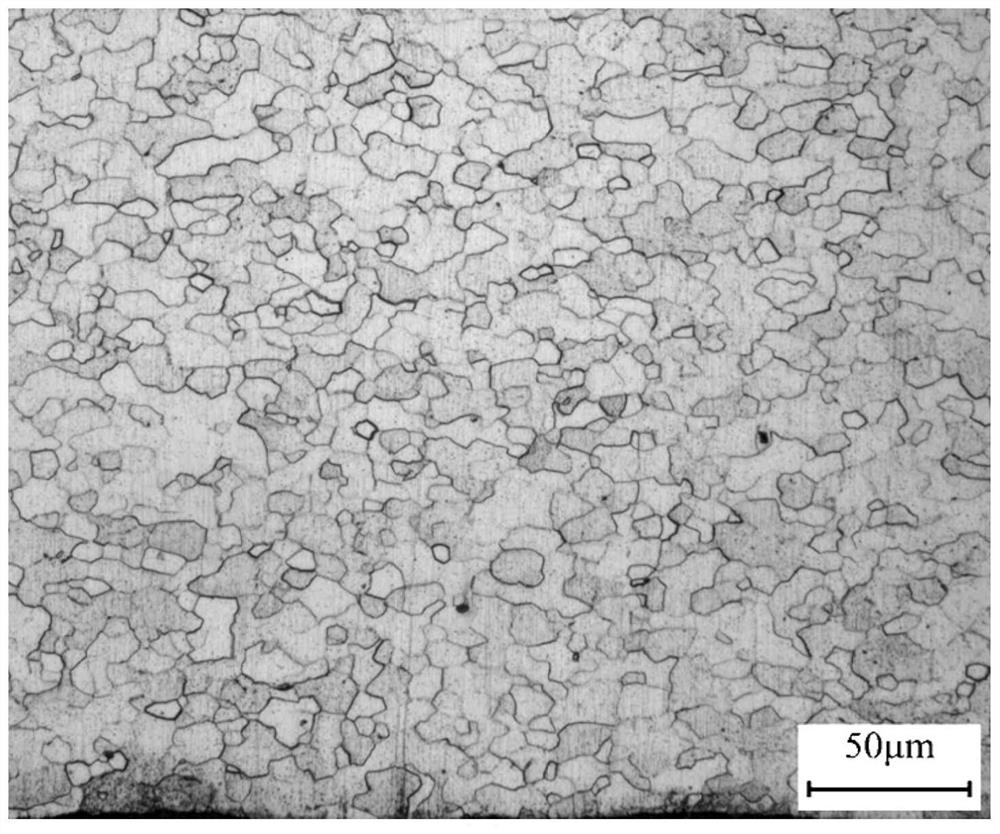

Image

Examples

Embodiment Construction

[0013] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

[0014] A metallographic etchant for ultra-low carbon steel provided by the invention is formed by mixing dehydrated alcohol, nitric acid and glacial acetic acid, the volume content of dehydrated alcohol accounts for 90%, the volume content of nitric acid accounts for 5%, and the remainder is glacial acetic acid, wherein, The mass percentage concentration of absolute ethanol is 99.5%, the mass percentage concentration of nitric acid is 65-68%, and the mass percentage concentration of glacial acetic acid is 99.5%. The corrosive agent provided by the present invention is obtained by mixing the three substances evenly.

[0015] The method of displaying the metallographic structure of ultra-low carbon steel is a one-step corrosion method, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com