Porcelain formula and manufacturing process thereof

A production process and formula technology, applied in the field of ceramic processing, can solve the problems of insufficient aesthetics, easy staining, bacteria breeding and wear resistance, etc., and achieve the effect of good gloss, high melt viscosity and white texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

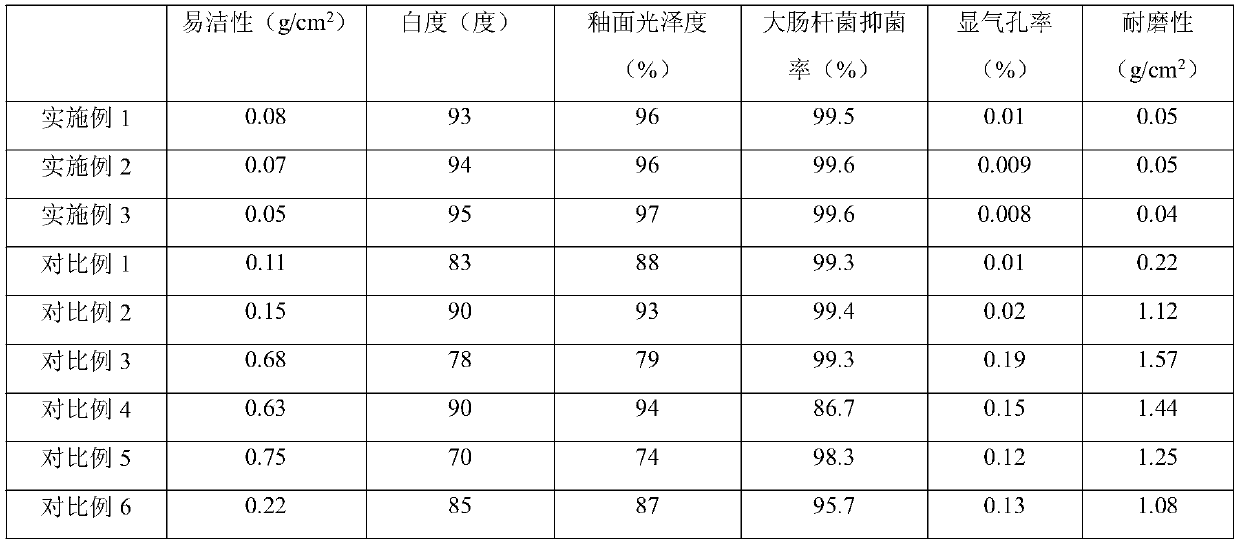

Examples

Embodiment 1

[0038]A kind of porcelain formula, including two parts of body material and glaze material, in parts by weight, the body material is made of the following raw materials: 100 parts of soft kaolin, 20 parts of burnt gemstones, 15 parts of potassium feldspar, large ball clay 2 parts; the glaze is made of the following raw materials: 100 parts of silicon dioxide, 25 parts of potassium fluoroaluminate, 5 parts of cerium dioxide, 7 parts of yttrium oxide, 5 parts of aluminum borate whiskers, 10 parts of nano-zinc oxide, 3 parts of cerium-graphene nanoparticles, 1 part of superfine powder of large ball mud.

[0039] The plain tire is fired by using the tire material, and the glaze material is used on both sides of the plain tire to form a glaze layer, and the thickness of the glaze layer is 0.2mm.

[0040] The cerium-graphene nanoparticles are prepared by the following method: first add cerium chloride and heat-treated liquid polyacrylonitrile into the solvent, stir and mix to obtain...

Embodiment 2

[0062] A kind of porcelain formula, including two parts of tire material and glaze material, in parts by weight, the tire material is made of the following raw materials: 100 parts of soft kaolin, 25 parts of burnt gemstones, 12 parts of potassium feldspar, large ball clay 3 parts; the glaze is made of the following raw materials: 100 parts of silicon dioxide, 20 parts of potassium fluoroaluminate, 8 parts of cerium dioxide, 4 parts of yttrium oxide, 7 parts of aluminum borate whiskers, 8 parts of nano-zinc oxide, 4 parts of cerium-graphene nanoparticles, 0.5 part of superfine powder of large ball mud.

[0063] The plain tire is fired by using the tire material, and the glaze layer is formed on both sides of the plain tire with a thickness of 0.4 mm.

[0064] The cerium-graphene nanoparticles are prepared by the following method: first add cerium chloride and heat-treated liquid polyacrylonitrile into the solvent, stir and mix to obtain liquid polyacrylonitrile-coated cerium p...

Embodiment 3

[0086] A kind of porcelain formula, including two parts of tire material and glaze material, in parts by weight, the tire material is made of the following raw materials: 100 parts of soft kaolin, 22 parts of burnt gemstones, 13 parts of potassium feldspar, large ball clay 2.5 parts; the glaze is made of the following raw materials: 100 parts of silicon dioxide, 23 parts of potassium fluoroaluminate, 6 parts of cerium dioxide, 5 parts of yttrium oxide, 6 parts of aluminum borate whiskers, 9 parts of nano-zinc oxide, 3.5 parts of cerium-graphene nanoparticles, 0.8 parts of large ball mud superfine powder.

[0087] Use the tire material to fire the plain tire, and use glaze material on both sides of the plain tire to form a glaze layer with a thickness of 0.3mm.

[0088] The cerium-graphene nanoparticles are prepared by the following method: first add cerium chloride and heat-treated liquid polyacrylonitrile into the solvent, stir and mix to obtain liquid polyacrylonitrile-coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com