Concrete glue reducing agent and preparation method thereof

A glue reducer and concrete technology, which is applied in the field of concrete glue reducer and its preparation, can solve the problems of large differences in molecular structure types, small molecular weight of glue reducers, and limited dispersion ability of glue reducers, so as to avoid strength and collapse The effect of reducing the degree of reduction, reducing the amount of cement, and reducing the loss of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]The preparation method of the polycarboxylic acid of the present invention is a preparation method well known in the art. In one embodiment, the preparation method of the polycarboxylic acid comprises the following steps: drop the monomer, the initiator and the chain transfer agent Add it into a solvent, react at 40-50 DEG C, adjust the pH to 6-7, and obtain the polycarboxylic acid.

[0039] Examples of initiators include, but are not limited to, persulfates, benzoyl peroxide, azobisisobutylcyanide, sodium dithionite, sodium formaldehyde sulfoxylate, ascorbic acid, sodium bisulfite, sodium metabisulfite, Sodium phosphite, dextrose monohydrate, maltodextrin. In a preferred embodiment, the initiator of the present invention accounts for 1-3 wt% of the weight of the monomer.

[0040] Examples of chain transfer agents include, but are not limited to, 3-mercaptopropionic acid, thioglycolic acid, mercaptoethanol, isopropanol. In one embodiment, the weight percentage of the c...

Embodiment 1

[0073] This example provides a glue reducer, the preparation raw material of the glue reducer includes 20 parts of substituted organic amine, 30 parts of polycarboxylic acid and 50 parts of water in parts by weight; the substituted organic amine is triethyl trisulfonate Esteramine and triethanolamine, the weight ratio is 1:2; The polycarboxylic acid is a modified polycarboxylic acid, and the preparation method of the modified polycarboxylic acid comprises the following steps: the monomer, the modifying agent, the initiator agent and chain transfer agent are added dropwise into the solvent, and after reacting at 45°C, the pH is adjusted to 6.5 to obtain the modified polycarboxylic acid; the monomers are acrylic acid, methacrylic acid, hydroxyethyl methacrylate, acrylic acid Dimethylaminoethyl ester, the weight ratio is 1:1.5:0.2:0.6, the initiator is sodium persulfate, accounting for 2wt% of monomer weight, the chain transfer agent is 3-mercapto propionic acid, accounting for mo...

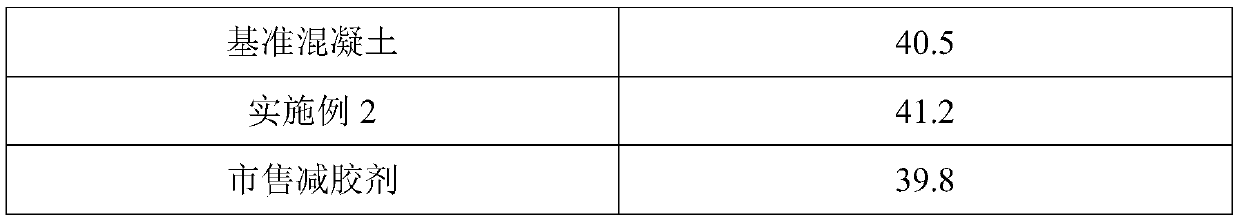

Embodiment 2

[0078] This example provides a glue reducer, the preparation raw material of the glue reducer includes 30 parts of substituted organic amine, 45 parts of polycarboxylic acid and 60 parts of water in parts by weight; the substituted organic amine is disulfonic acid group- Ethanol-based diethyl ester amine and triisopropanolamine, the weight ratio is 1:3; the polycarboxylic acid is a modified polycarboxylic acid, and the preparation method of the modified polycarboxylic acid comprises the following steps: The monomer, modifying agent, initiator and chain transfer agent are added dropwise into the solvent, and after reacting at 45°C, the pH is adjusted to 6.5 to obtain the modified polycarboxylic acid; the monomers are acrylic acid, methacrylic acid, methacrylic acid hydroxyethyl acrylate, dimethylaminoethyl acrylate, the weight ratio is 1:1.5:0.2:0.6, the initiator is sodium persulfate, the weight percentage of the monomer is 2wt%, and the chain transfer agent is 3 -mercaptoprop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com