Gas-phase polymerization method for catalyzing olefin homopolymerization by using late transition metal catalyst

A post-transition metal, gas-phase polymerization technology, which is applied in the field of gas-phase polymerization of olefin homogeneous polymerization catalyzed by late-transition metal catalysts, can solve the problem of polyolefins needing to be dried, the discharge of organic waste liquid has a great impact on the environment, and the post-treatment process requires higher requirements, etc. problems, to achieve the effect of improving industrial production efficiency, zero organic waste discharge, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The following examples are used to illustrate specific embodiments of the present invention. The data provided include the gas phase polymerization data of different catalysts and the test data of the resulting polymer. All sensitive substances are stored in a glove box. Ethylene gas is removed by water removal. Oxygen column purification.

[0047] All preparations of the following examples were carried out according to standard Schlenk techniques.

[0048] The reagents used in the following examples were obtained from commercial sources unless otherwise specified, and were used directly without purification (dehydration and drying treatment may be performed if necessary).

[0049] The degree of branching of the polymer obtained in the following examples is obtained by nuclear magnetic resonance, and the deuterated solvent used for nuclear magnetic resonance is dried and distilled before use. Unless otherwise stated, 1 H and 13 C NMR spectra were recorded by a JNM-EC...

Synthetic example 1-8

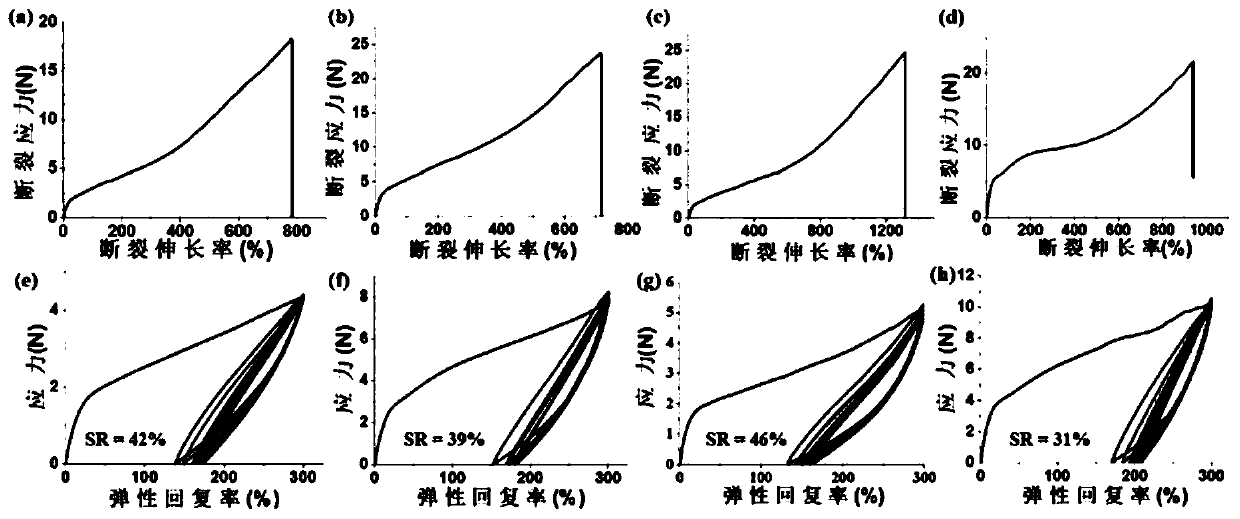

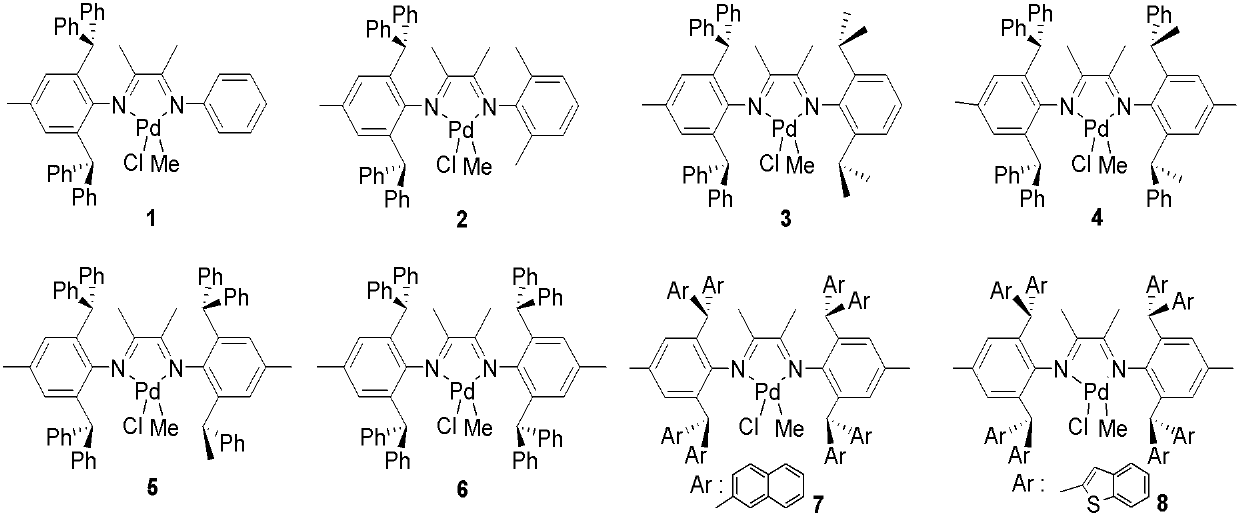

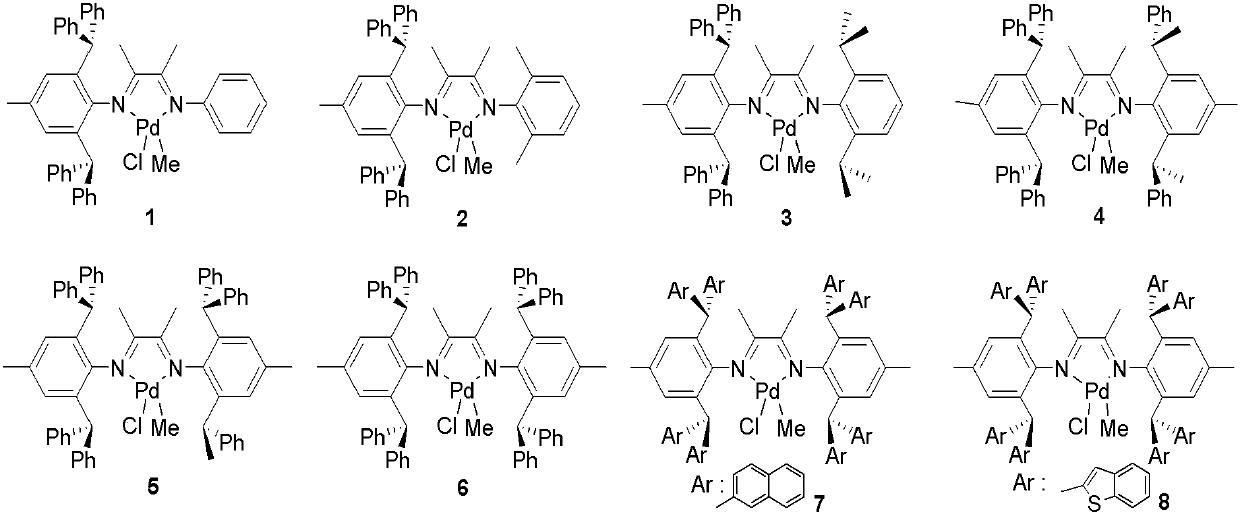

[0054] Synthesis Example 1-8: Using Catalyst 1-8 to Catalyze Gas Phase Polymerization of Ethylene to Obtain Homopolymer of Ethylene

[0055] In a glove box or a fume hood, in a narrow-necked flask, mix 10 μmol of the corresponding α-diimine palladium complex of formula 1-8 (as a late transition metal catalyst) with 20 μmol of tetrakis(3,5-bis(tri Fluoromethyl)phenyl)sodium borate (NaBArF, as a cocatalyst) was mixed in 2 mL of dichloromethane and fully stirred to dissolve to obtain a catalyst solution.

[0056] The obtained catalyst solution was poured into a dried 350mL glass thick-walled pressure reactor along the reactor wall, and the catalyst solution was evenly coated on the reactor wall by gentle shaking, and in dichloromethane solvent After volatilization, a catalyst film layer is formed on the reactor wall.

[0057] The reactor with the catalyst film layer formed on the wall is connected with the ethylene high-pressure gas cylinder through a vacuum pipeline, and after ...

Synthetic example 9-14

[0066] Synthesis Examples 9-14: In the case of using the same catalyst (i.e. Catalyst 6), investigate the gas phase polymerization of ethylene under different reaction pressures, times and temperatures

[0067] The reaction process was the same as that of Synthesis Example 6 above, except that the reaction pressure, time and temperature were changed as shown in Table 2 below to carry out gas-phase polymerization, and the desired ethylene homopolymer was obtained. The results are shown in Table 2.

[0068] Table 2

[0069]

[0070] a Activity unit is 10 4 g / (mol Pd h);

[0071] b m n is the number average molecular weight of the obtained ethylene homopolymer;

[0072] c PDI is the molecular weight distribution of gained ethylene homopolymer;

[0073] d b rs For the degree of branching of the obtained ethylene homopolymer, i.e. the number of methyl groups corresponding to every 1000 methylene groups;

[0074] e T m Be the fusing point of gained ethylene homopolyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com