Graphene/molybdenum disulfide composite material and liquid phase preparation method thereof

A technology of molybdenum disulfide and composite materials, applied in the fields of molybdenum sulfide, chemical instruments and methods, carbon compounds, etc., can solve the problems of no reports and no published patents, and achieve low experimental cost, high reaction yield, and safe experimental operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

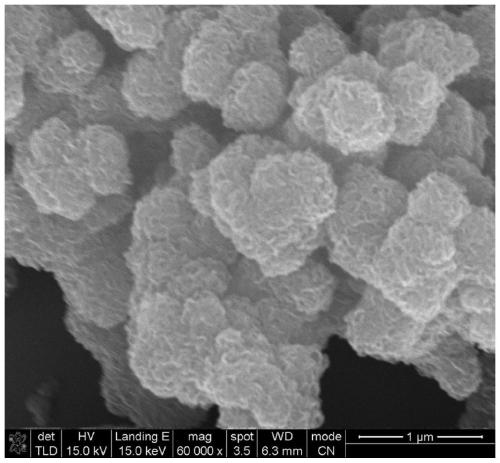

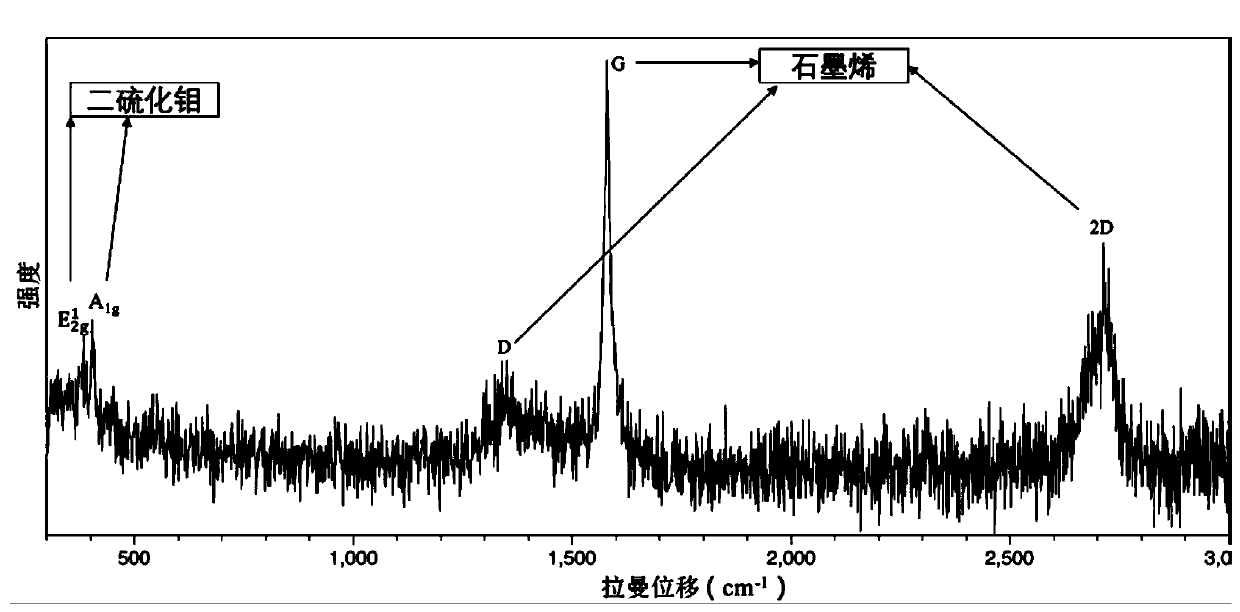

Image

Examples

Embodiment 1

[0027] The liquid phase preparation method of graphene / molybdenum disulfide composite material comprises the following steps:

[0028] Step 1, according to the mol ratio of graphene and molybdenum disulfide is that 10:1 takes by weighing respectively the graphene powder of 24mg and the ammonium tetrathiomolybdate powder of 52.056mg;

[0029] Step 2, dissolving the ammonium tetrathiomolybdate powder taken in step 1 in 15mL deionized water to form a mixed solution;

[0030] Step 3, stirring the mixed solution obtained in step 2 for 40 min at a speed of 700 rpm to form a uniformly dispersed solution;

[0031] Step 4, adding the graphene powder taken in step 1 into the uniformly dispersed solution obtained in step 3 to form a mixed solution;

[0032] Step 5, stirring the solution obtained in step 4 for 20 min at a speed of 700 rpm to form a uniformly dispersed solution;

[0033] Step 6. Pour the uniformly dispersed solution obtained in Step 5 into a stainless steel autoclave lin...

Embodiment 2

[0040] The liquid phase preparation method of graphene / molybdenum disulfide composite material comprises the following steps:

[0041] Step 1, according to the mol ratio of graphene and molybdenum disulfide is 5:1 to weigh the graphene powder of 12mg and the ammonium tetrathiomolybdate powder of 52.056mg respectively;

[0042] Step 2, dissolving the ammonium tetrathiomolybdate powder taken in step 1 in 15mL deionized water to form a mixed solution;

[0043] Step 3, stirring the mixed solution obtained in step 2 for 40 min at a speed of 700 rpm to form a uniformly dispersed solution;

[0044] Step 4, adding the graphene powder taken in step 1 into the uniformly dispersed solution obtained in step 3 to form a mixed solution;

[0045] Step 5, stirring the solution obtained in step 4 for 20 min at a speed of 700 rpm to form a uniformly dispersed solution;

[0046] Step 6. Pour the uniformly dispersed solution obtained in Step 5 into a stainless steel autoclave lined with polytetra...

Embodiment 3

[0051] The liquid phase preparation method of graphene / molybdenum disulfide composite material comprises the following steps:

[0052] Step 1, according to the mol ratio of graphene and molybdenum disulfide is 0.5:1 to weigh the graphene powder of 1.2mg and the ammonium tetrathiomolybdate powder of 52.056mg respectively;

[0053] Step 2, dissolving the ammonium tetrathiomolybdate powder taken in step 1 in 15mL deionized water to form a mixed solution;

[0054] Step 3, stirring the mixed solution obtained in step 2 for 40 min at a speed of 700 rpm to form a uniformly dispersed solution;

[0055] Step 4, adding the graphene powder taken in step 1 into the uniformly dispersed solution obtained in step 3 to form a mixed solution;

[0056] Step 5, stirring the solution obtained in step 4 for 20 min at a speed of 700 rpm to form a uniformly dispersed solution;

[0057] Step 6. Pour the uniformly dispersed solution obtained in Step 5 into a stainless steel autoclave lined with poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com