Pure-phase polygonal W2C nano material and preparation method thereof

A nanomaterial, polygonal technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of high activity, difficult synthesis of C nanomaterials, low activity, etc., and achieves mild preparation conditions. Environmentally friendly, simple and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The advantages of the preparation method provided by the application are as follows:

[0050] (1) The precursors used in this method are all inorganic substances, and the W is controlled by controlling the amount of water added. 2 C exposed edges, by controlling the heat treatment temperature to control W 2 The particle size of C crystals realizes the generation of pure phase W 2 C while controlling the morphology of the material;

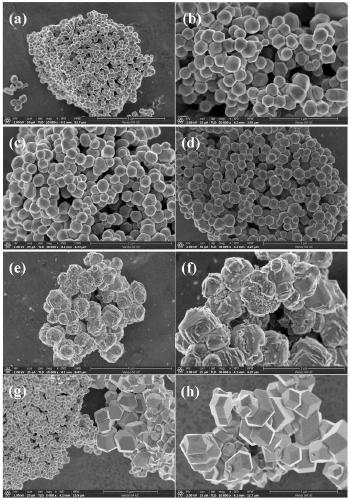

[0051] (2) The pure phase W prepared by this method 2 C nanoparticles have a nearly dodecahedral shape, and the particle size can range from 100 to 500nm;

[0052] (3) The method is simple and easy, the preparation conditions are mild, the environment is friendly, and industrial mass production can be realized.

Embodiment 1

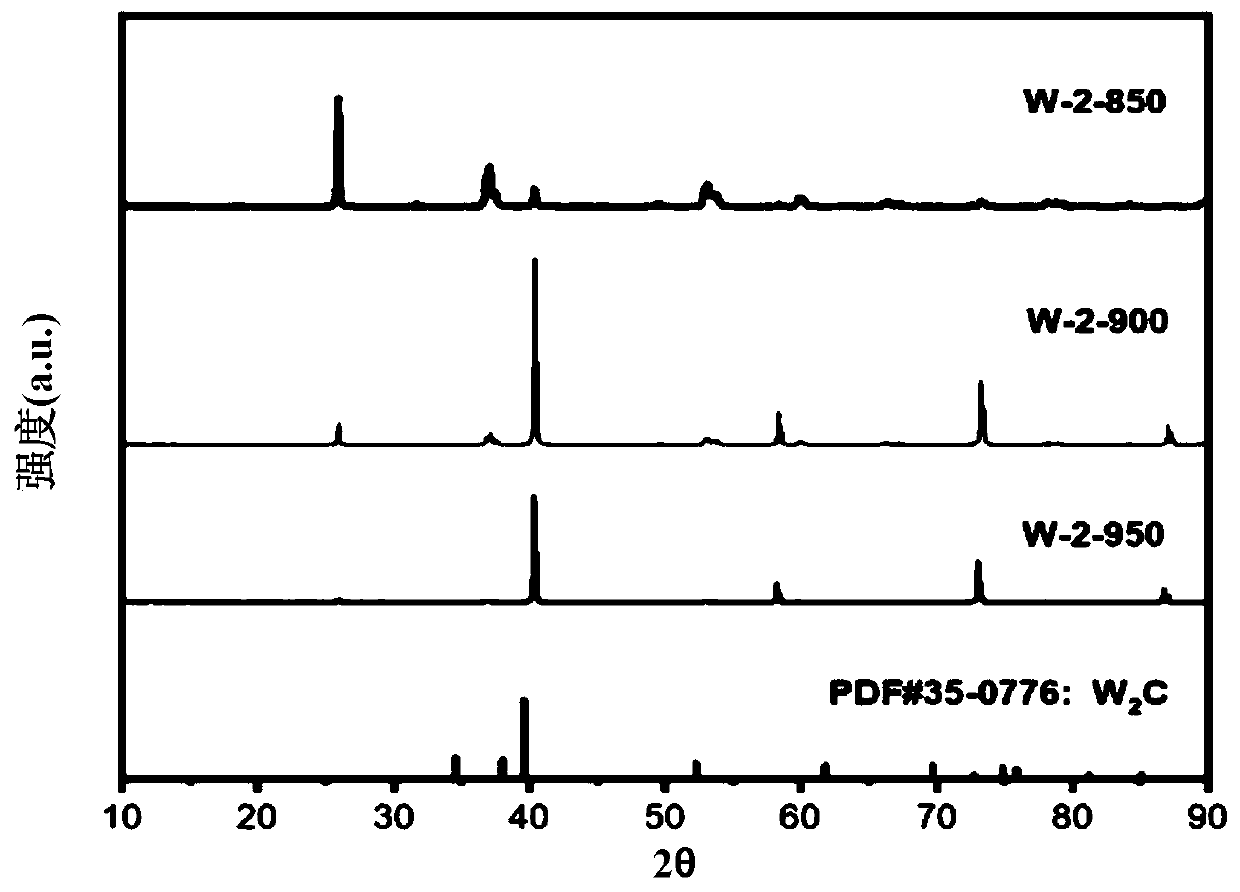

[0055] Dissolve 5mmol of ammonium tungstate (ie 15.2129g) in 20mL of ethylene glycol solution, place it in a water bath at 80°C and stir for 8 hours to obtain a uniform white solution. Then, 32 mmol of melamine (ie 4.03584 g) was dissolved in another 20 mL of ethylene glycol solution, and deionized water with a volume 0.4 times that of the ethylene glycol solution was added, placed in a water bath at 80°C and stirred for 8 hours to obtain a uniform white solution. The above two white solutions were mixed and stirred at 25°C for 1 h to obtain a white flocculent precipitate. Afterwards, the white precipitate was collected by centrifugation, washed three times with ethanol, and dried in a vacuum oven at 70° C. for 12 h. Finally, the collected precipitate was placed in 95% H 2 Heat treatment at 900℃ for 2h in 5% Ar atmosphere to obtain pure phase W 2 C nanomaterials, such as figure 1 Shown in the W-2-900 spectral line in the XRD pattern of.

[0056] The particle size of prepar...

Embodiment 2

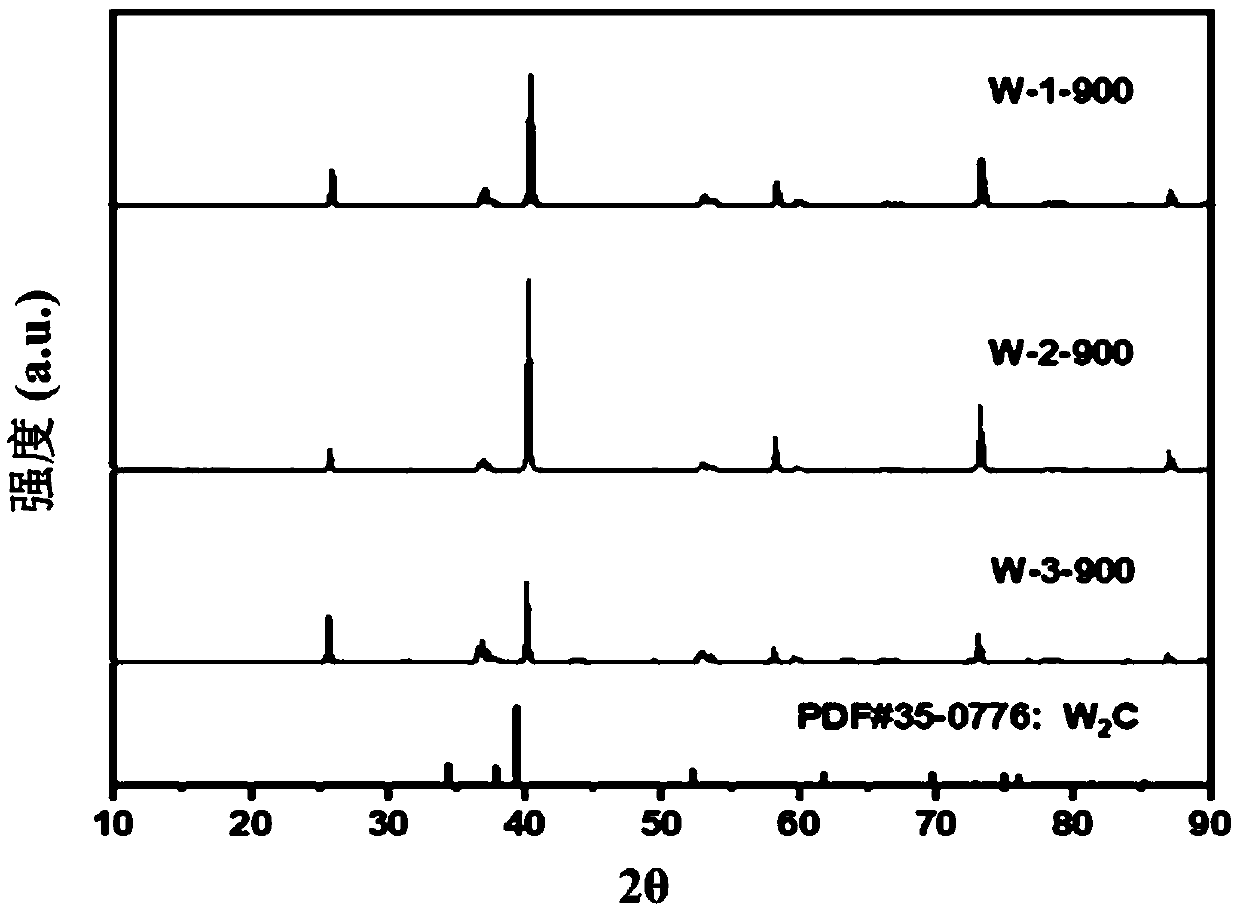

[0058] 32mmol melamine (ie 4.03584g) was dissolved in 20mL ethylene glycol solution, and deionized water with a volume 0.2 times that of the ethylene glycol solution was added, and other operating conditions were the same as in Example 1. The structure of the obtained material is the pure phase W 2 C, such as figure 1 Shown in the W-1-900 spectral line in the XRD pattern of the XRD, particle diameter is about 250nm (table 1), and morphology is nearly dodecahedral, as image 3 The SEM photographs in a and b are shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com