Integrated structure, battery/electrolytic cell and preparation method of battery stack

A technology of solid oxides and blocks, which is applied to fuel cell components, solid electrolyte fuel cells, fuel cells, etc., to achieve the effects of reducing sealing workload, overcoming the complexity of processing technology, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

preparation example Construction

[0097] In specific implementation, the preparation method for preparing the first pore-forming agent block and the second pore-forming agent block includes: mold pressing or screen printing.

[0098] In a second aspect, the present invention provides a method for preparing a solid oxide fuel cell / electrolyzer, the method comprising:

[0099] Using the method described in the first aspect above, preparing the integrated structure of the connector and the support body;

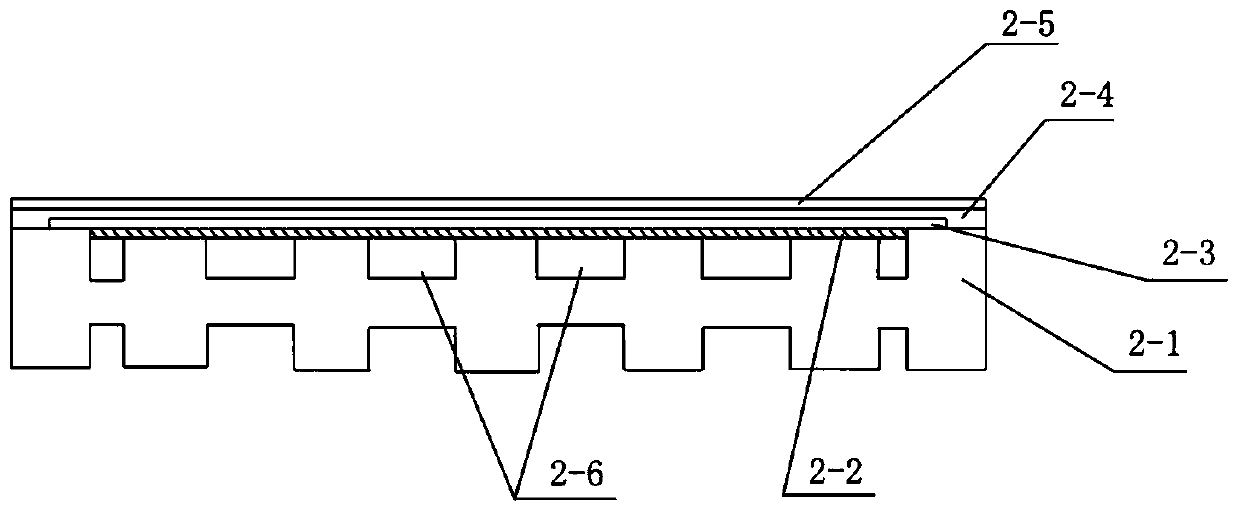

[0100] coating the anode material on the surface layer region of the integrated structure of the connector and the support body to obtain an anode layer;

[0101] coating an electrolyte material on the surface of the anode layer to obtain an electrolyte layer;

[0102] coating the cathode material on the surface of the electrolyte layer to obtain a solid oxide fuel cell / electrolyzer;

[0103] the second pore former mass is removed to form an anode gas channel through which anode gas flows into the anode;

[0...

Embodiment 1

[0114] By pre-preparing with such as Figure 4 and Figure 5 The mold corresponding to the ammonium bicarbonate block of shown runner shape adopts the method for pressing and has such as Figure 4 and Figure 5 The ammonium bicarbonate block of two kinds of runner shapes, the ammonium bicarbonate block is the ammonium bicarbonate block of 8cm╳8cm. The iron-chromium alloy metal powder is mixed with the ammonium bicarbonate to obtain the precursor powder of the porous metal support body, wherein the content of the ammonium bicarbonate is 20%wt.

[0115] will be like Figure 4 The ammonium bicarbonate block in the shape of a runner is placed on the bottom of the mold of 10cm╳10cm, and the iron-chromium alloy metal powder with a particle size of about 20μm is laid on such as Figure 4 shown above the ammonium bicarbonate with runner shape and completely covered with iron chromium alloy metal powder as Figure 4 Shown have the ammonium bicarbonate of runner shape (comprising t...

Embodiment 2

[0119] Pure chromium metal powder was mixed with ammonium bicarbonate to obtain porous metal support precursor powder, wherein the content of ammonium bicarbonate was 9%wt. The ammonium bicarbonate block is the ammonium bicarbonate block of 8cm x 16cm in the present embodiment.

[0120] prepared with such Figure 4 The pore-forming agent (ammonium bicarbonate) in the shape of the flow channel is placed on the bottom of the mold of 10cm╳20cm, and the pure chromium metal powder with a particle size of about 40 μm is laid on the pore-forming agent (ammonium bicarbonate) in the shape of the flow channel on, and overwrite it, then will have as Figure 5 The channel-shaped pore-forming agent (ammonium bicarbonate) is placed on it and the pure chromium metal powder is laid, and then the precursor powder of the porous metal area is laid on the uppermost layer, and finally the metal powder is used to fill the mold and the porous metal The space around the domain precursor powder layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com