Graphene-based selective absorption film system and absorbing layer preparation method thereof

A graphene-based, selective technology, applied in coatings, solar thermal power generation, etc., can solve the problems of few research work, imperfect research on sub-wavelength interference structure shaping and regulation, and yet to be developed, etc., and achieves simple process and excellent spectrum. selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

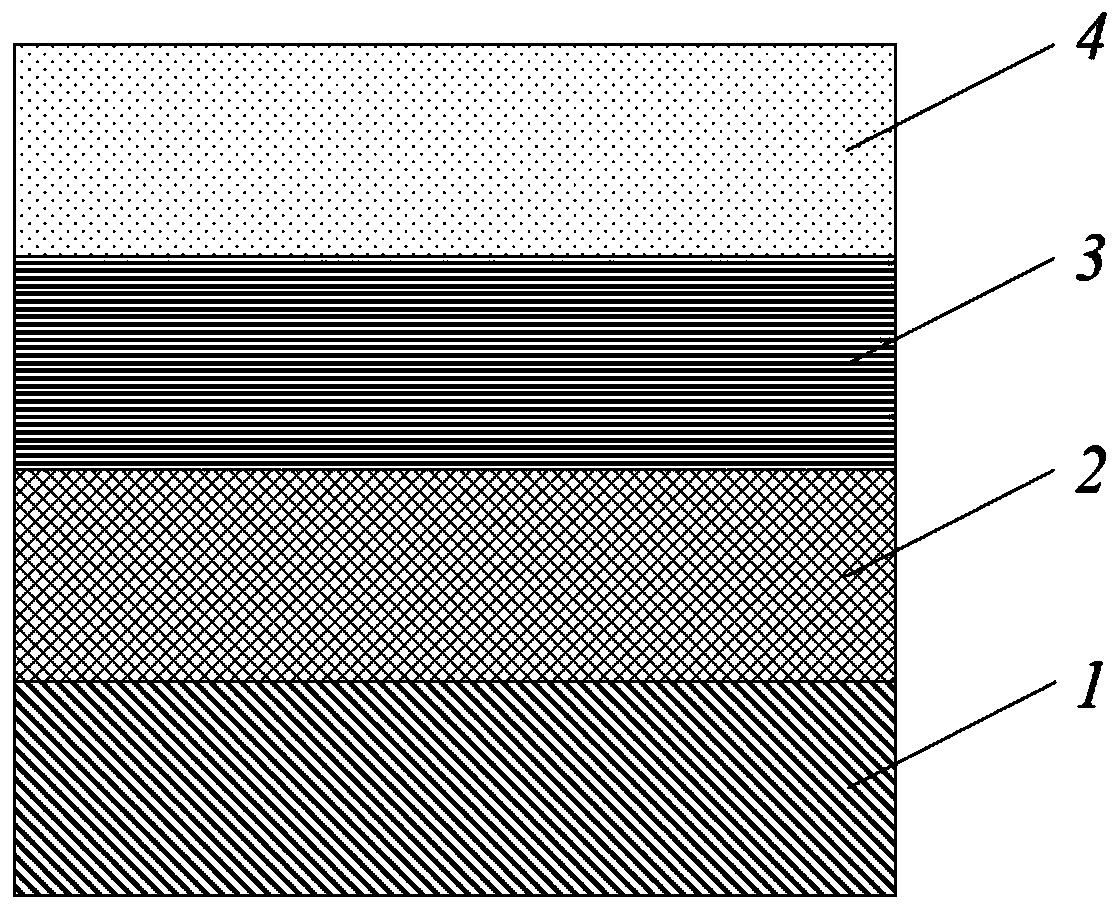

[0034] (1) Preparation of the base layer and the infrared reflective layer: In some embodiments of the present invention, a polished metal sheet is selected as the base layer and the infrared reflective layer at the same time, and the upper surface of the metal sheet should be polished until the mean square roughness drops below 10nm . It should be noted that the base layer does not have to be the same as the infrared reflective layer, and can be any material. At the same time, the upper surface of the metal sheet is polished to meet the spectral function of the infrared reflective layer, and at the same time, the thickness of the infrared reflective layer should be ensured to be above 70nm.

[0035] (2) Pretreatment of the surface of the infrared reflective layer: After removing the attached impurities on the surface of the polished metal sheet, ultrasonically clean it in acetone and ethanol for 15 to 30 minutes, and store it in vacuum after purging with nitrogen;

[0036] (...

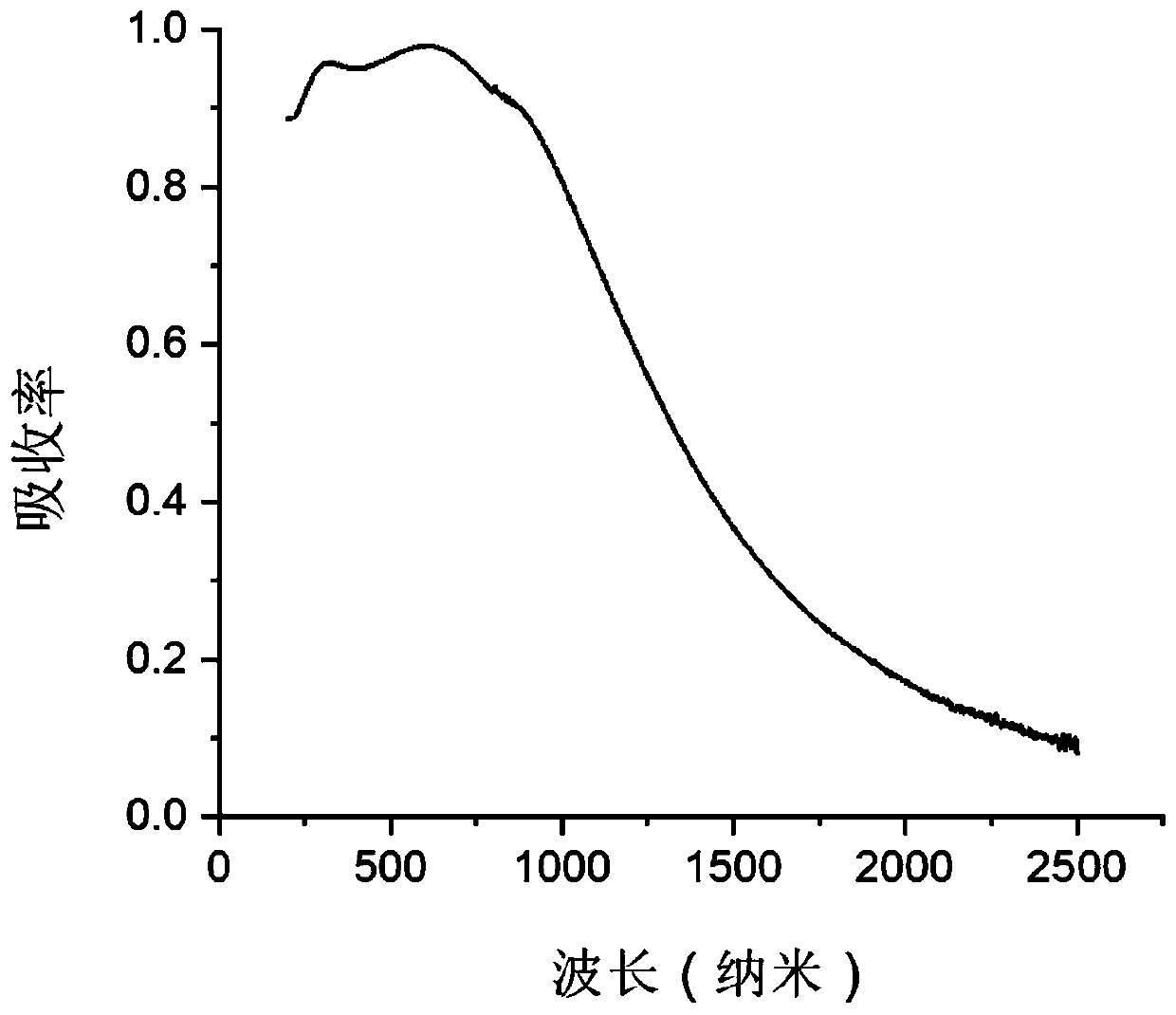

Embodiment 1

[0054] The overall scheme and steps of embodiment 1 are the same as the above-mentioned specific implementation process, and the more specific description has:

[0055] 1. Use polished metal Al sheet as the substrate and infrared reflection layer at the same time;

[0056] 2. The anti-reflection layer was prepared by the sol-gel method, and the selected material was silica nano-sol;

[0057] 3. adopt the method for drying after solution coating to prepare graphene absorbing layer, further have in this method:

[0058] 3.1 The concentration of the graphene oxide aqueous solution obtained in step S1 is 10mg·mL -1 ;

[0059] 3.2 In step S2, the low-surfactant solution is selected as ethanol, and the volume ratio of ethanol to the graphene oxide aqueous solution is 10:1;

[0060] 3.3 The coating method used in step S3 is spin coating, the rotation speed is 2000-6000 rpm, and the number of coatings is 50-1000 times;

[0061] 3.4 The reduction treatment method used in step S4 is...

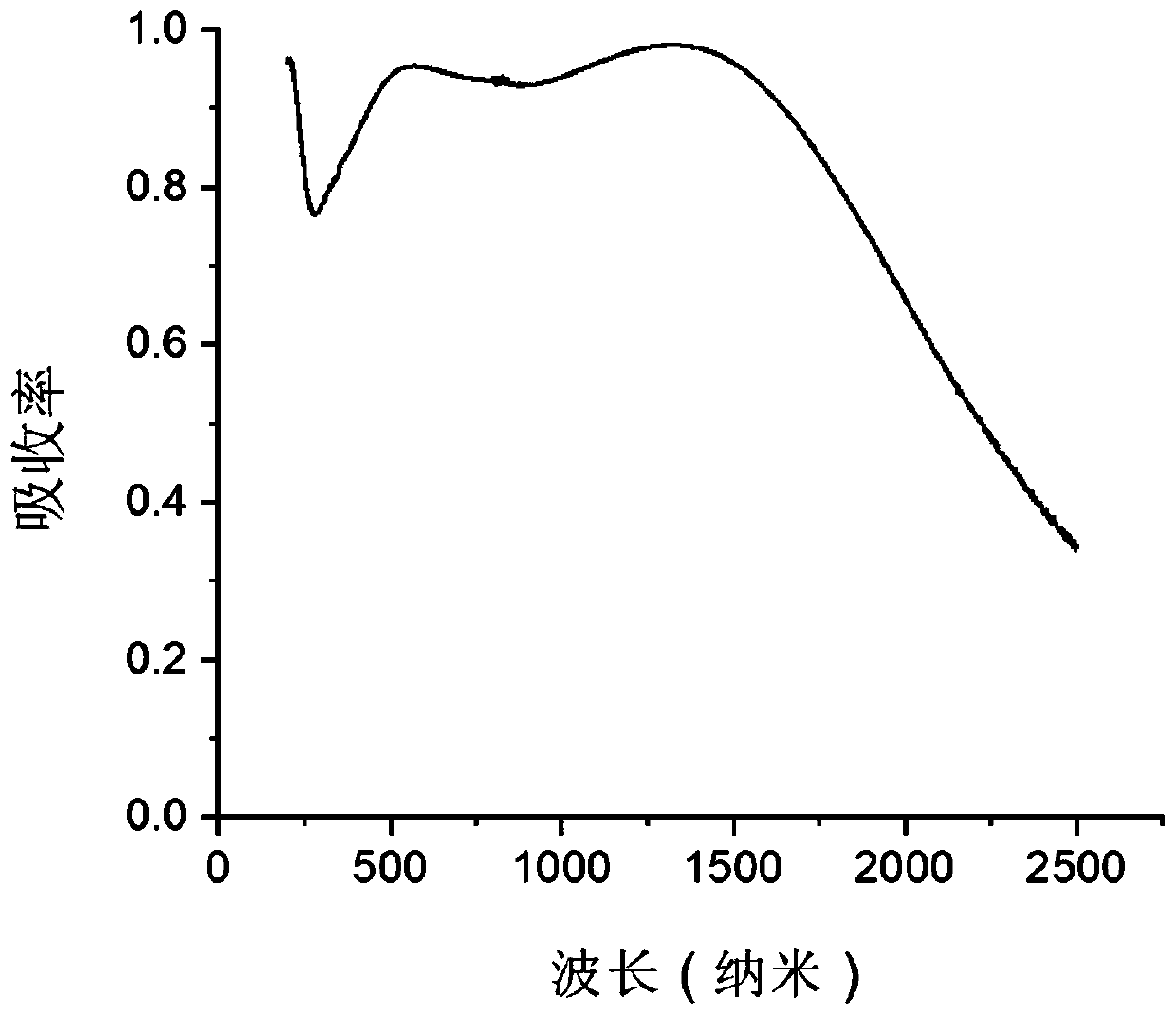

Embodiment 2

[0064] Embodiment 2 is basically the same as Embodiment 1, the difference is the thickness of the obtained graphene absorbing layer.

[0065] 1. Use polished metal Al sheet as the substrate and infrared reflection layer at the same time;

[0066] 2. The anti-reflection layer was prepared by the sol-gel method, and the selected material was silica nano-sol;

[0067] 3. adopt the method for drying after solution coating to prepare graphene absorbing layer, further have in this method:

[0068] 3.1 The concentration of the graphene oxide aqueous solution obtained in step S1 is 10mg·mL -1 ;

[0069] 3.2 In step S2, the low-surfactant solution is selected as ethanol, and the volume ratio of ethanol to the graphene oxide aqueous solution is 10:1;

[0070] 3.3 The coating method used in step S3 is spin coating, the rotation speed is 2000-6000 rpm, and the number of coatings is 50-1000 times;

[0071] 3.4 The reduction treatment method used in step S4 is high-temperature heat trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com