Metal-plated graphite sheet and preparation method thereof

A graphite sheet and metal plating technology, which is applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problems of affecting heat dissipation effect, affecting shielding effect, poor thermal conductivity of adhesive, etc., to achieve enhanced thermal conductivity Sex and electromagnetic shielding performance, reduce production cost, prolong the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

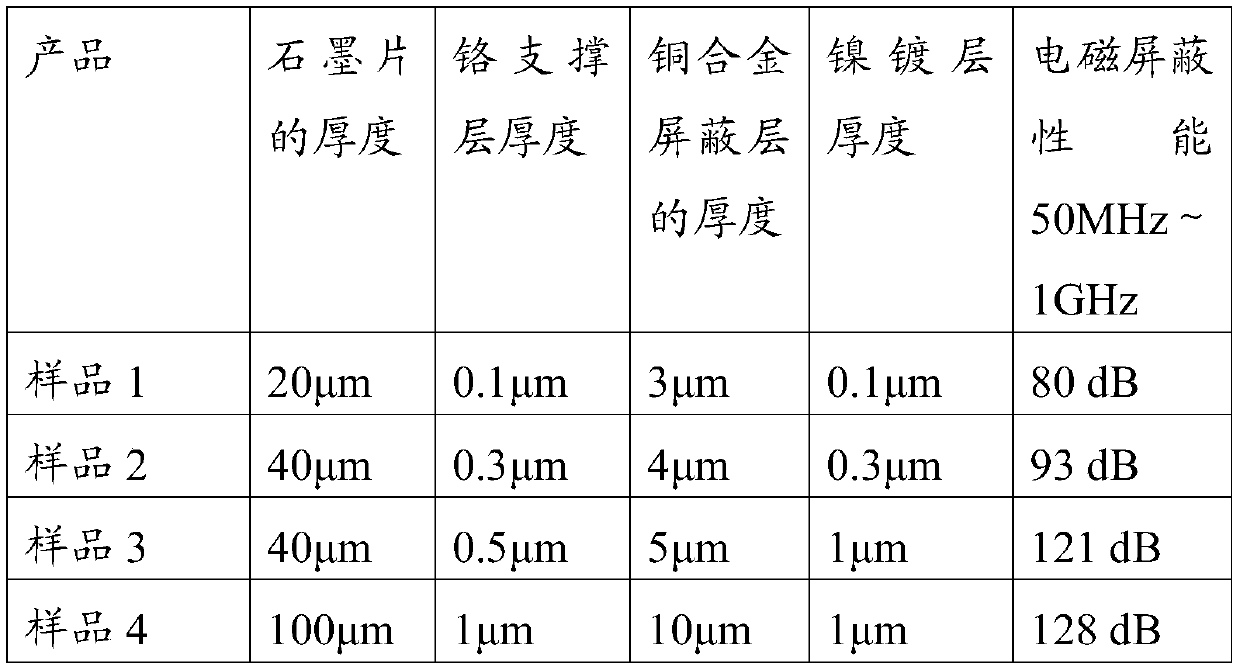

Examples

preparation example Construction

[0017] The invention provides a kind of preparation method of metal-coated graphite sheet, comprises the steps:

[0018] Step 1, plating chromium metal on the graphite sheet by magnetron sputtering to obtain the first graphite sheet with a chromium support layer;

[0019] Step 2, plating the copper alloy on the copper alloy target onto the chromium support layer of the first graphite sheet by magnetron sputtering to obtain a second graphite sheet with a copper alloy shielding layer;

[0020] The weight percent composition of the copper alloy target material is: Cr 0.1-0.5%, Al 1-3%, and the rest is Cu;

[0021] Step 3. Plating nickel metal on the copper alloy shielding layer of the second graphite sheet by magnetron sputtering to obtain a metal-coated graphite sheet.

[0022] The metal-plated graphite sheet of the present invention is provided with three coatings with different functions, including chromium support layer, copper alloy shielding layer and nickel metal layer su...

Embodiment 1

[0032] A preparation method of metal-coated graphite sheet, comprising the steps of:

[0033] Step 1, plating chromium metal on the graphite sheet by magnetron sputtering to obtain the first graphite sheet with a chromium support layer;

[0034] Step 2, plating the copper alloy on the copper alloy target onto the chromium support layer of the first graphite sheet by magnetron sputtering to obtain a second graphite sheet with a copper alloy shielding layer;

[0035] The preparation method of the copper alloy target material is as follows: preparing Cr, Al and Cu raw materials, and then using induction melting method to conduct melting and alloying at a temperature of 1100-1200° C. in a vacuum atmosphere, and then, the alloyed The melt is cast into a mold to obtain a copper alloy target.

[0036] The weight percent composition of the copper alloy target material is: Cr 0.1%, Al 1%, and the rest is Cu;

[0037] Step 3, plating nickel metal on the copper alloy shielding layer of...

Embodiment 2

[0040] A preparation method of metal-coated graphite sheet, comprising the steps of:

[0041] Step 1, plating chromium metal on the graphite sheet by magnetron sputtering to obtain the first graphite sheet with a chromium support layer;

[0042] Step 2, plating the copper alloy on the copper alloy target onto the chromium support layer of the first graphite sheet by magnetron sputtering to obtain a second graphite sheet with a copper alloy shielding layer;

[0043] The preparation method of the copper alloy target material is as follows: preparing Cr, Al and Cu raw materials, and then using induction melting method to conduct melting and alloying at a temperature of 1100-1200° C. in a vacuum atmosphere, and then, the alloyed The melt is cast into a mold to obtain a copper alloy target.

[0044] The weight percent composition of the copper alloy target material is: Cr 0.3%, Al 2%, and the rest is Cu;

[0045] Step 3. Plating nickel metal on the copper alloy shielding layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com