A modified water-based polyurethane adhesive for bonding intelligent audio mesh and its preparation method and use method

A technology of water-based polyurethane and intelligent audio, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as difficulty in applying glue, low bonding strength, and poor heat resistance, and achieve Improve body strength and flexibility, improve initial adhesion and bonding strength, and enhance the effect of initial adhesion and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

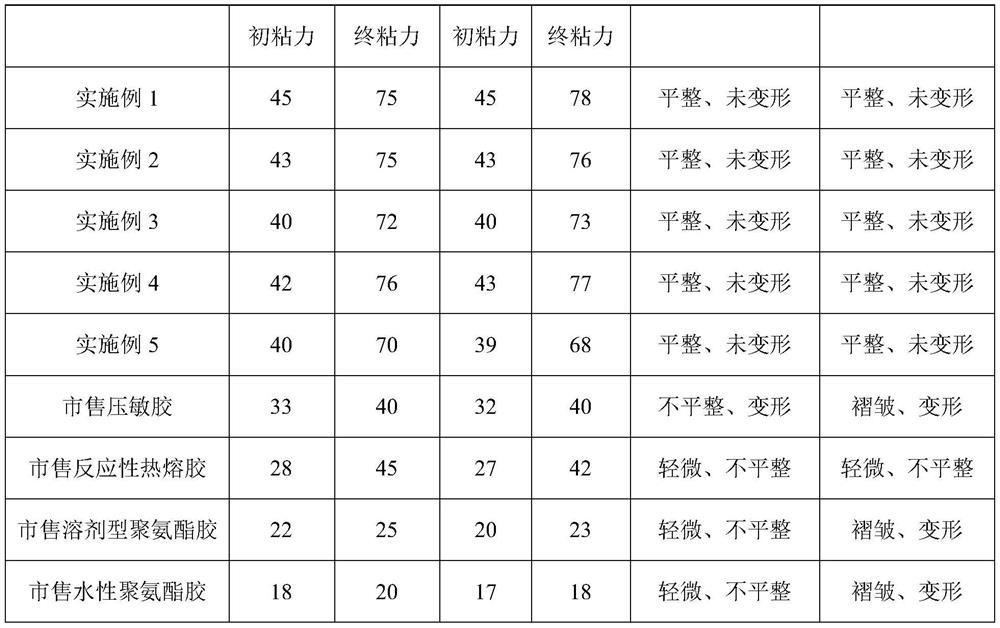

Examples

Embodiment 1

[0089] A modified water-based polyurethane adhesive used for bonding intelligent audio mesh, consisting of a main agent and a curing agent;

[0090] The main ingredient contains the following components in parts by weight:

[0091] Adwel 1629 25 copies;

[0092] Adwel 1630B 25 parts;

[0093] 5 parts of diethylene glycol butyl ether;

[0094] 0.5 parts of 2-amino-2-methyl-1-propanol;

[0095] 15 parts of modified aqueous acrylate suspension;

[0096] Nano silver titanium 1 part;

[0097] Vesmody U905 8 parts;

[0098] 20 parts of deionized water;

[0099] The curing agent is Aquolin161, and its dosage accounts for 4% of the main agent dosage;

[0100] Among them, the mass ratio of the water-based polyurethane dispersion to the modified water-based acrylate suspension is 3.33:1.

[0101] The preparation method of above-mentioned auxiliary agent is:

[0102] Add water-based polyurethane dispersions Adwel 1629 and Adwel 1630B into the mixer, and add diethylene glycol but...

Embodiment 2

[0130] A modified water-based polyurethane adhesive used for bonding intelligent audio mesh, consisting of a main agent and a curing agent;

[0131] The main ingredient contains the following components in parts by weight:

[0132] Adwel 1629 33 copies;

[0133] Dispercoll U54 30 parts;

[0134] 3.4 parts of propylene glycol propyl ether;

[0135] 0.4 parts of 2-amino-2-methyl-1-propanol;

[0136] 25 parts of modified aqueous acrylate suspensions;

[0137] Nano silver titanium 0.64 parts,

[0138] Vesmody U601 5.3 parts,

[0139] 13 parts of deionized water;

[0140] The curing agent is Aquolin278, and its dosage accounts for 6% of the main agent dosage;

[0141] Among them, the mass ratio of water-based polyurethane dispersion to modified water-based acrylate suspension is 2.52:1;

[0142]The preparation method of above-mentioned main agent is:

[0143] Add the water-based polyurethane dispersion Adwel 1629 and Dispercoll U54 into the mixer, and add propylene glycol ...

Embodiment 3

[0174] A modified water-based polyurethane adhesive used for bonding intelligent audio mesh, consisting of a main agent and a curing agent;

[0175] The main ingredient contains the following components in parts by weight:

[0176] Dispercoll U56 42 parts;

[0177] Dispercoll U53 35 parts;

[0178] 1.8 parts of diethylene glycol butyl ether;

[0179] 0.25 parts of 2-amino-2-methyl-1-propanol;

[0180] 20 parts of modified aqueous acrylate suspension;

[0181] 0.33 parts of nano-silver titanium;

[0182] Vesmody U605 3.1 parts;

[0183] 7 parts of deionized water;

[0184] The curing agent is Desmodur DN, and its dosage accounts for 9% of the main agent dosage;

[0185] Among them, the mass ratio of water-based polyurethane dispersion to modified water-based acrylate suspension is 3.85:1;

[0186] The preparation method of above-mentioned main agent is:

[0187] Add the water-based polyurethane dispersions Dispercoll U56 and Dispercoll U53 into the mixer, and add dieth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com