Polyimide composite material and preparation method thereof and substrate

A technology of polyimide and composite materials, which is applied in the field of polyimide composite materials and their preparation methods and substrate substrates, can solve the problems that the performance is difficult to meet the comprehensive performance standards, and achieve the improvement of mechanical properties and thermal stability Sex, good bending resistance, enhanced compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a kind of preparation method of described polyimide composite material, polyimide composite material described in the present invention can be prepared by this method, and described preparation method comprises the following steps:

[0048] S1. Polymerizing diamine and dianhydride to obtain a polyamic acid solution;

[0049] S2. Introducing inorganic nanoparticles into the polyamic acid solution to obtain a polyamic acid / inorganic nanoparticle mixed solution; and,

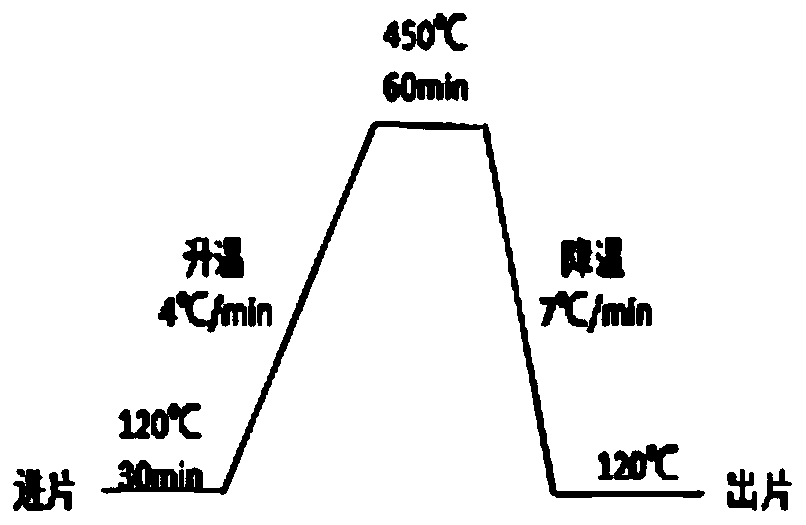

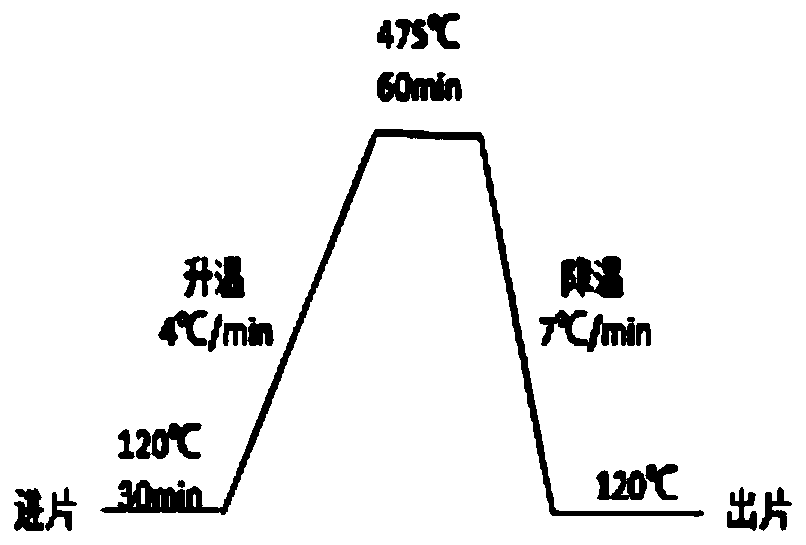

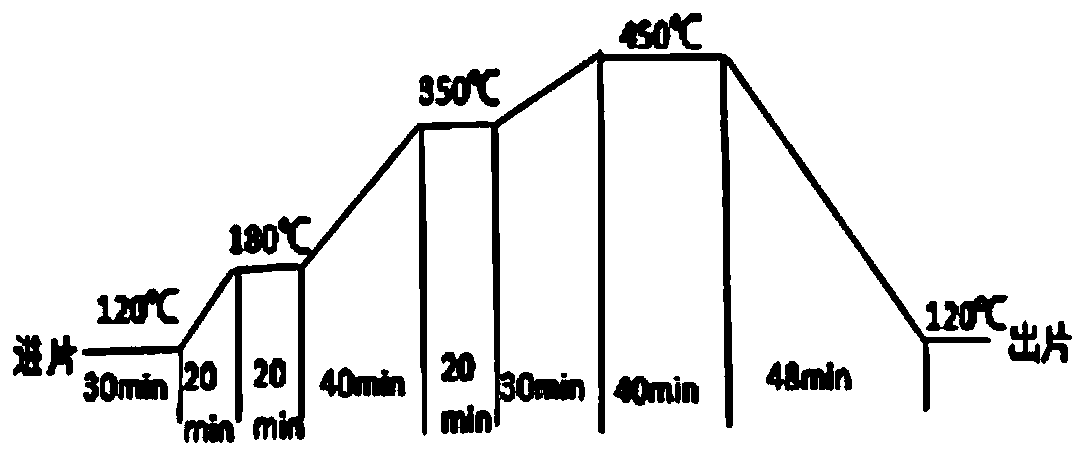

[0050] S3, cross-linking and curing the polyamic acid / inorganic nanoparticle solution to obtain a polyimide composite material;

[0051] The molecular structural formula of the polyimide composite material includes polyimide structural units and inorganic nanoparticles connected to the polyimide structural units in a chemical bond.

[0052] In a nutshell, the three preparation steps of the polyimide composite material can be summarized as follows: 1) preparation of polyam...

Embodiment 1

[0085] In this example, compound A uses diamine-bis(3-aminophenyl)-3,5-bis(trifluoromethyl)phenylphosphine oxide, and compound B uses 4,4'-biphenyl ether dianhydride , the inorganic nanoparticles are magnesium oxide nanoparticles, the compound D is magnesium ethoxide, and the aprotic solvent is a mixture of N,N-dimethylcaproamide (DMAC) and N-methylpyrrolidone (NMP), And DMAC / NMP=v / v=0.2-2, so as to prepare the polyimide composite material.

[0086]Weigh 1.5-10 mmol of diamine-bis(3-aminobenzene)-3,5-bis(trifluoromethyl)phenylphosphine oxide, dissolve in the aprotic solvent and stir evenly to obtain the first reaction solution ; Weighing 1.5-17 mmol of 4,4'-biphenyl ether dianhydride dissolved in the aprotic solvent and stirring uniformly to obtain a second reaction solution; adding the second reaction solution to the first reaction solution, Stir at room temperature for 24-96 hours to make it fully dissolve; then, perform suction filtration under a vacuum environment, and th...

Embodiment 2

[0094] The biggest difference from Example 1 is that in this example, 3,3',4,4'-biphenyltetracarboxylic dianhydride was selected as the compound B for synthesizing the polyimide composite material. In this embodiment, the reaction scheme for preparing the polyimide composite material is shown in the following formula:

[0095] as well as

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile properties | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com