Preparation method of UV-cured organic silicon modified hyperbranched polyurethane material

A hyperbranched polyurethane, silicone technology, applied in the direction of polyurea/polyurethane coatings, polyurea/polyurethane adhesives, adhesive types, etc. Change and other problems, to achieve the effect of simple production, excellent bonding performance, easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Under nitrogen protection, first mix 100g polytetramethylene ether glycol with an average molecular weight of 2000, 30g HO(Me 2 SiO) 100 Add H and 1.34g trimethylolpropane into a 250mL three-necked flask equipped with a mechanical stirrer and a thermometer. After stirring evenly, start reducing the pressure and heating to 110°C / 130mmHg to remove water for 2 hours, then cool down to 40°C, and add dropwise 0.10g of dibutyltin dilaurate, add 21.65g of IPDI dropwise, react at 40°C for 6h, add 8.45g of hydroxypropyl methacrylate, continue to react at 40°C for 8h, and obtain 161.44g of acrylate-terminated hyperbranched organosilicon modification permanent polyurethane;

[0040] (2) Under mechanical stirring at 50°C, add 78.54g 3-mercaptopropyltrimethoxysilane, 48.75g dimethyldiethoxysilane, 47.98g methyltrimethoxysilane, 1.62g hexamethyldisiloxane Add dropwise the mixture of 56.2g deionized water and 3.5g 36.5% concentrated hydrochloric acid in the mixture of alkane (ac...

Embodiment 2-14

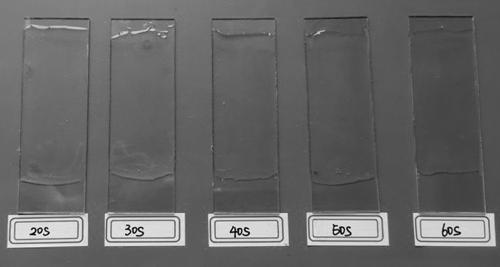

[0043] According to the preparation method of Example 1, different molar ratios of acrylate group and mercaptopropyl group were selected, and after UV curing, the properties of the obtained cured product are shown in Table 1.

Embodiment 15

[0053] (1) Under nitrogen protection, first mix 100g polytetramethylene glycol with an average molecular weight of 500, 30g polytetramethylene ether glycol with an average molecular weight of 1000, 40g

[0054] HO(Me 2 SiO) 400 (MePhSiO) 400 (CH 2 CH 2 CH 2 CF 3 MeSiO) 200 Add H and 4.0g trimethylolpropane into a 250mL three-necked flask equipped with a mechanical stirrer and a thermometer. After stirring evenly, start to decompress and heat up to 130°C / 130mmHg to remove water for 0.5h, then cool down to 90°C, drop Add 0.20g dibutyltin dilaurate, add dropwise a mixture of 18gIPDI and 11gTDI, react at 90°C for 1h, add 16.9g-4-hydroxybutyl methacrylate, continue to react at 90°C for 2h, and obtain 220.1g acrylate sealant terminal hyperbranched silicone-modified polyurethane.

[0055] (2) Under mechanical stirring at 40°C, add 39.27g 3-mercaptopropyltrimethoxysilane, 64.34g dimethyldiethoxysilane, 32.83g methyltrimethoxysilane, 1.62g hexamethyldisiloxane Add dropwise a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

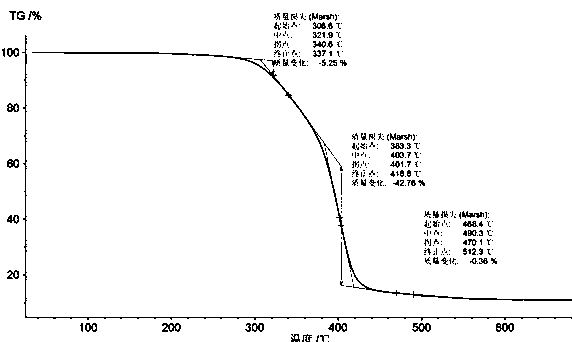

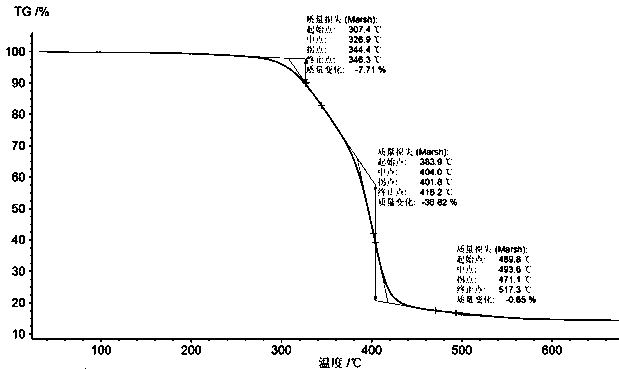

| thermal decomposition temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com