Production device and process of nitro-sulfur-based water-soluble fertilizer

A production process and production device technology, applied in the field of production devices of nitrosulfur-based water-soluble fertilizers, can solve problems such as flatulence, poor water solubility, and hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

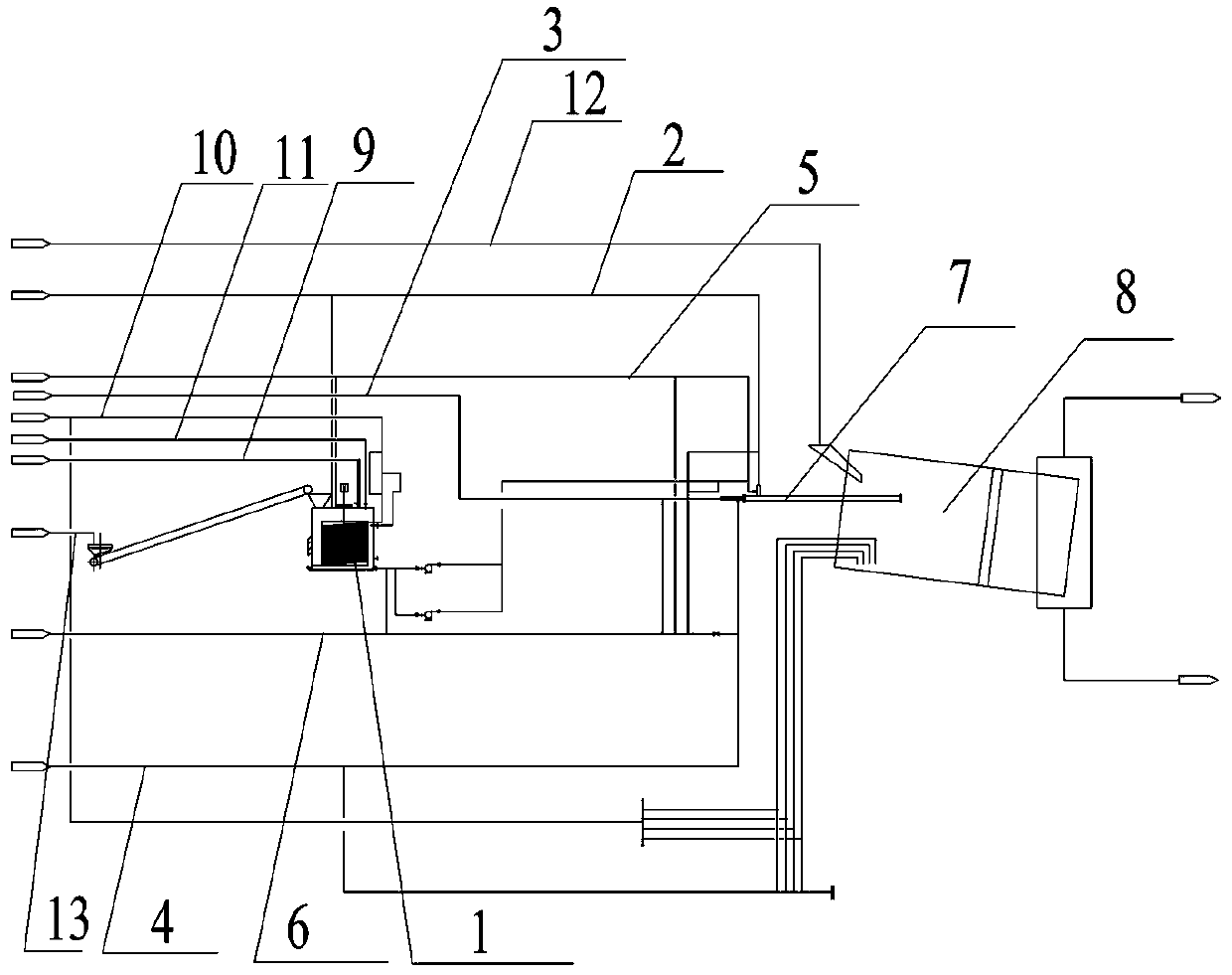

[0045] The production device of nitrosulfur-based water-soluble fertilizer, mixing tank 1, phosphoric acid pipeline 2, sulfuric acid pipeline 3, liquid ammonia pipeline 4, washing liquid pipeline 5, and medium-pressure steam pipeline 6 are respectively connected to the tubular reactor 7 through pipelines, and the tubular reaction The device is arranged in the granulator 8, and the granulator 8 is connected to the nitrosulfur-based water-soluble fertilizer storage device. The mixing tank 1 is provided with a slurry feed pipe 9 , a low-pressure steam feed pipe 10 , a process water feed pipe 11 and a monoammonium phosphate feed pipe 14 . The granulator 8 is also provided with a granulator solid storage tank feed pipe 12 and a low-pressure steam feed pipe 10 .

Embodiment 2

[0047] A production process of nitrosulfur-based water-soluble fertilizer, characterized in that,

[0048] (1) Put the mixture of potassium salt, ammonium nitrate, and humic acid in a mass ratio of 1:1:0.3 as a solid raw material from the raw material system, and add it to the granulator;

[0049] (2) Pumping monoammonium phosphate, ammonium nitrate, process water, and low-pressure steam to the slurry storage tank to form a mass fraction of 66% monoammonium phosphate slurry, the moisture content of the monoammonium phosphate slurry is 22%, and the temperature is 110 ℃;

[0050] (3) Monoammonium phosphate slurry, ammonium nitrate phosphorus, washing liquid (the washing liquid comes from the washing liquid produced after the concentrated phosphoric acid is pumped into the tail washing system), concentrated phosphoric acid to form a blended slurry (the water content of the blended slurry is 14%, the temperature is 110°C, the mass ratio of the monoammonium phosphate slurry, ammon...

Embodiment 3

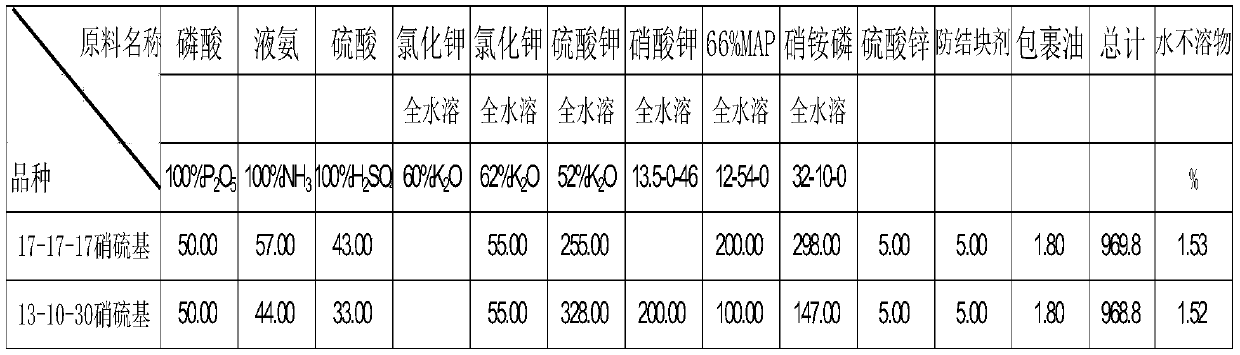

[0052] (1) Put the solid raw materials of potassium salt, ammonium nitrate and EDTA into the raw material system and add them into the granulator. The feed rate is 6.24t / h ammonium nitrate, 1.18t / h potassium chloride, 5.12t / h potassium sulfate, 0.98t / h chelating agent, and 0.105t / h zinc sulfate monohydrate.

[0053] (2) The flow rate of 66% monoammonium phosphate slurry is 2.21m 3 / h, 48%P 2 o 5 The flow rate of concentrated phosphoric acid is 1.65m 3 / h, 0.91t / h liquid ammonia and 2.67m 3 / h washing solution is pumped into the tubular reactor together.

[0054] (3) Spray the slurry in the tubular reactor to granulate in the granulator, and dry it under hot air at 125-250°C to prepare a 17-17-17 nitrosulfur-based water-soluble fertilizer. The pH value is 5.8-6.0.

[0055] The product quality indicators are obtained as follows:

[0056] 1. Total nitrogen 16.12%

[0057] 2. Ammonia nitrogen 11.92%

[0058] 3. Nitrate nitrogen 4.20%

[0059] 4. Total phosphorus 19.36% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance to crushing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com