High-thermal-stability fluorescent ceramic for white LED/LD and preparation method thereof

A high thermal stability, fluorescent ceramic technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of temperature quenching, thermal stability deterioration of fluorescent ceramics, etc., to eliminate lattice distortion, improve service performance, improve The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: preparation chemical formula is (Gd 0.06 Y 0.938 Ce 0.002 ) 3 (Al 0.4 sc 0.6 ) 2 Al 3 o 12 Fluorescent Ceramics

[0036] (1) Set the target product quality as 60g, according to the chemical formula (Gd 0.06 Y 0.938 Ce 0.002 ) 3 (Al 0.4 sc0.6 ) 2 al 3 o 12 The stoichiometric ratio of each element in takes aluminum oxide (18.515g), yttrium oxide (30.365g), gadolinium oxide (3.118g), scandium oxide (7.908g) and cerium oxide (0.99g) respectively as raw material powder; Mix raw material powder, 0.00156g tetraethyl orthosilicate, 0.0078g PEI, and 120ml of absolute ethanol, add 120g of alumina balls with a diameter of 1mm, and perform ball milling in an alumina ball mill tank with a ball milling speed of 180r / min and a ball milling time of 25h ;

[0037] (2) Put the mixed slurry after ball milling in step (1) in a blast drying oven at 50°C for 10 hours, and pass the dried mixed powder through an 80-mesh sieve, sieve it 5 times, and then calcinate...

Embodiment 2

[0047] Embodiment 2: preparation chemical formula is (Gd 0.07 Y 0.928 Ce 0.002 ) 3 (Al 0.3 sc 0.7 ) 2 al 3 o 12 Fluorescent Ceramics

[0048] (1) Set the target product mass to 60g, weigh alumina (17.384g), yttrium oxide (29.773g), gadolinium oxide (3.605g), and scandium oxide (9.144g) respectively according to the stoichiometric ratio of each element in the chemical formula and cerium oxide (0.098g) as the raw material powder; mix the raw material powder, 0.00234g ethyl orthosilicate, 0.00936g PEI, 130ml absolute ethanol, add 150g of alumina balls with a diameter of 2mm, and carry out the process in an alumina ball mill tank Ball milling, the ball milling speed is 190r / min, and the ball milling time is 22h;

[0049] (2) Put the mixed slurry after ball milling in step (1) into a blast oven at 55°C and dry for 15 hours. The dried mixed powder is passed through a 90-mesh sieve, sieved 4 times, and then calcined in an air atmosphere to remove residual For organic matter...

Embodiment 3

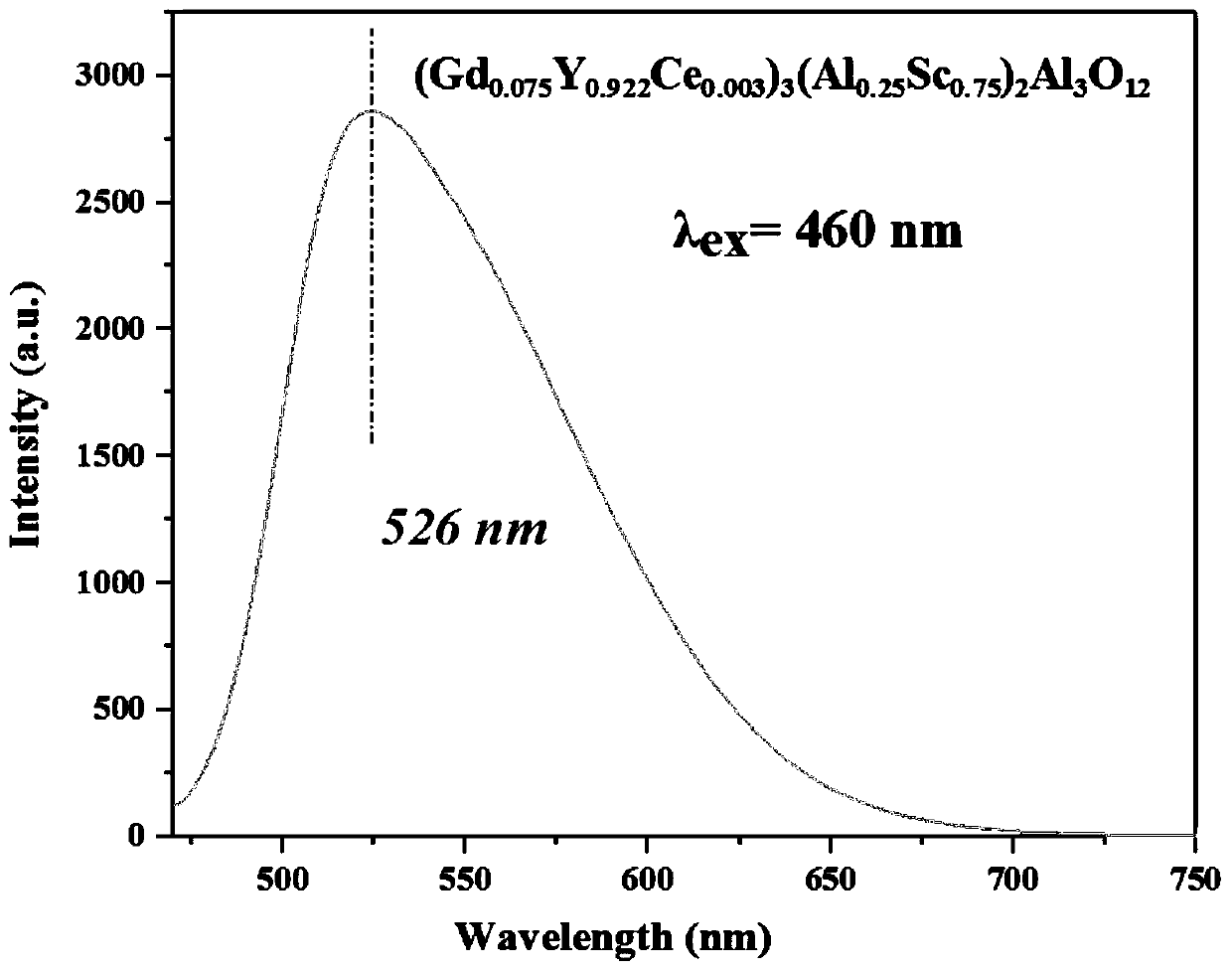

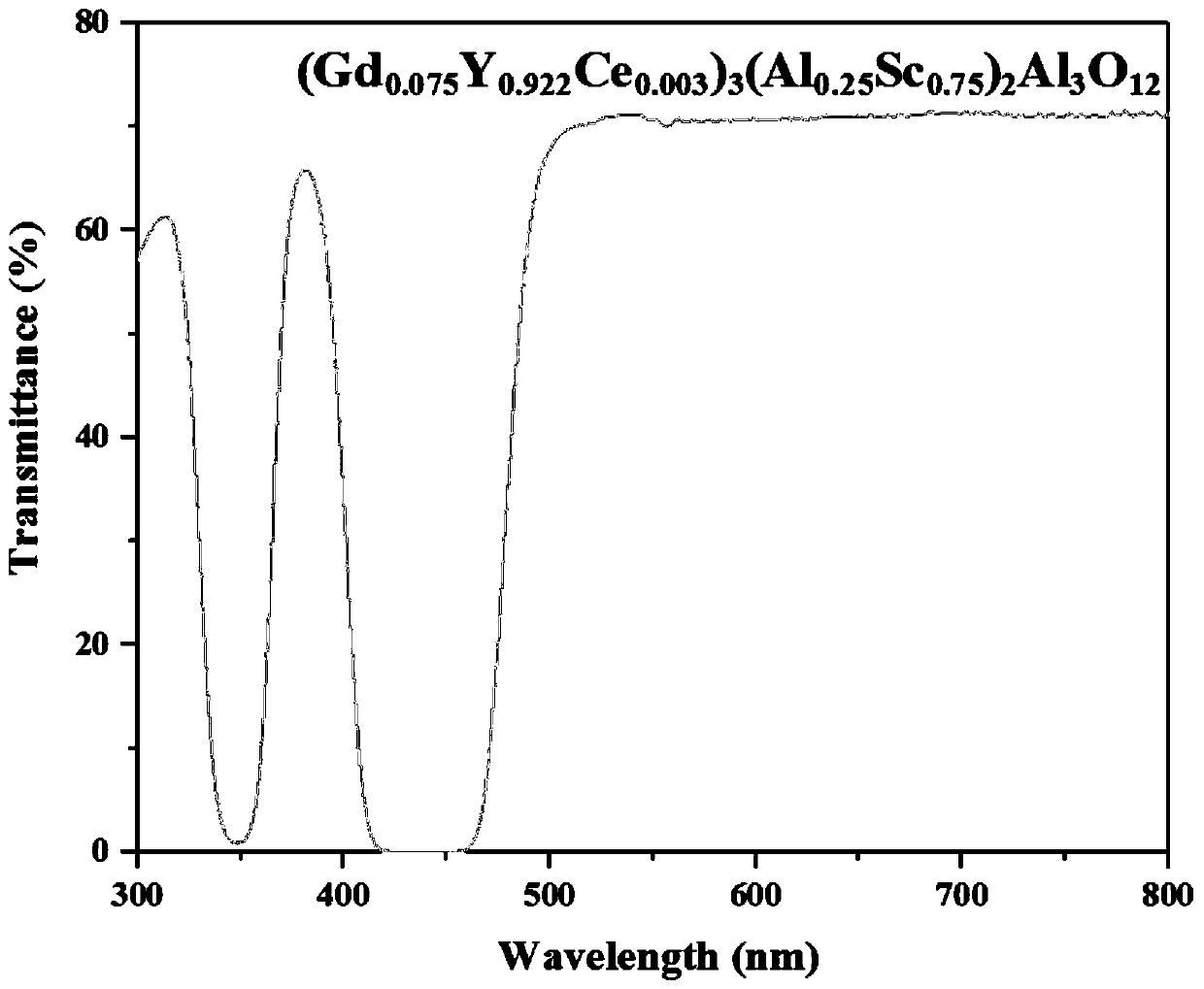

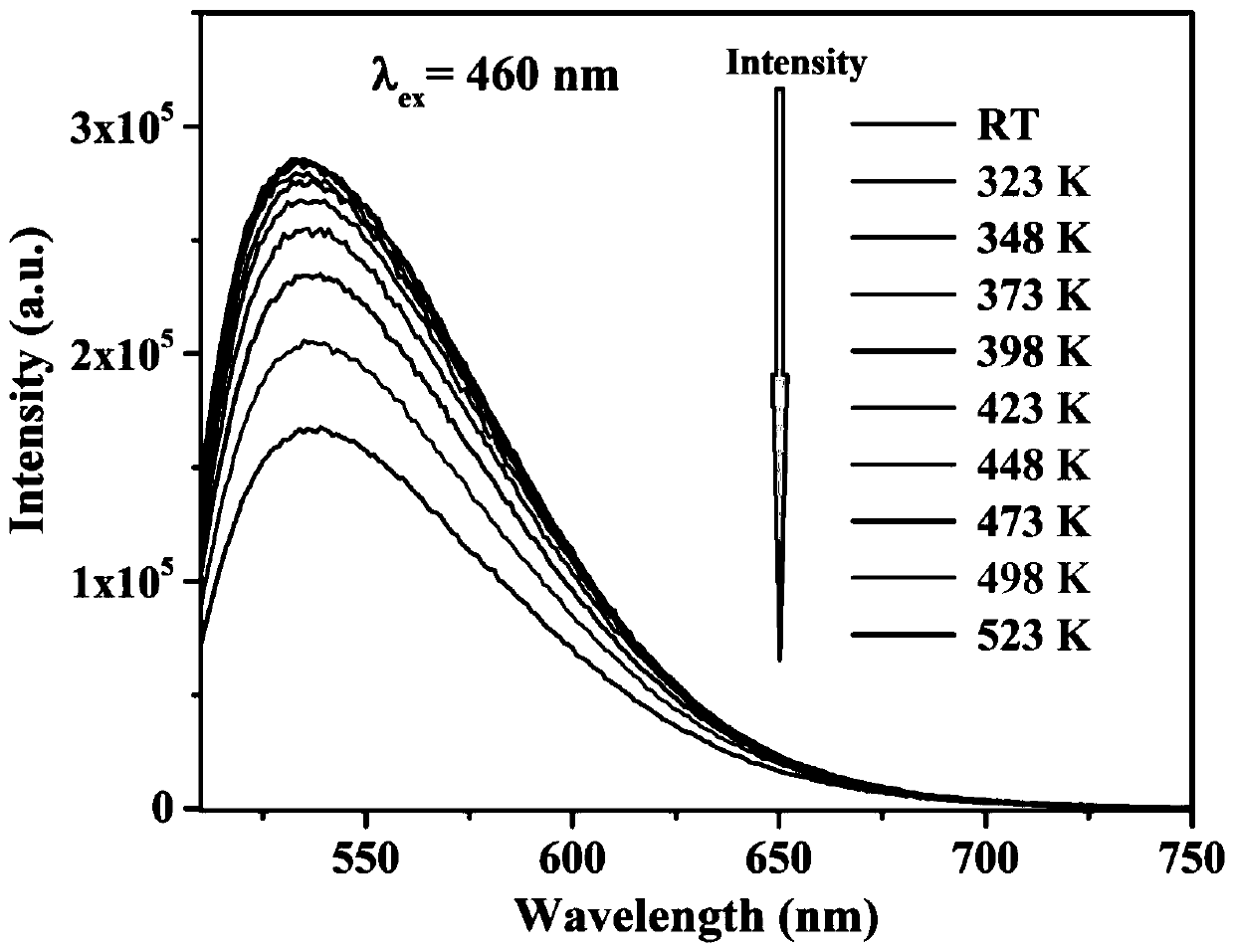

[0059] Embodiment 3: preparation chemical formula is (Gd 0.075 Y 0.922 Ce 0.003 ) 3 (Al 0.25 sc 0.75 ) 2 al 3 o 12 Fluorescent Ceramics

[0060] (1) Set the target product mass to 60g, weigh alumina (16.822g), yttrium oxide (29.442g), gadolinium oxide (3.845g), and scandium oxide (9.751g) respectively according to the stoichiometric ratio of each element in the chemical formula and cerium oxide (0.146g) as the raw material powder; the raw material powder, 0.00312g tetraethyl orthosilicate, 0.0156gPEI, 150ml absolute ethanol are mixed, and a diameter of 5mm is added to the alumina ball 180g, and the grinding process is carried out in an alumina ball mill tank. Ball milling, the ball milling speed is 200r / min, and the ball milling time is 25h;

[0061] (2) Put the mixed slurry after ball milling in step (1) in a blast drying oven at 60°C for 20 hours, and pass the dried mixed powder through a 100-mesh sieve, sieve 3 times, and then calcine in an air atmosphere to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fwhm | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com