High-strength and high-thermal-conductivity aluminum alloy material and heat treatment process thereof

An aluminum alloy material, high thermal conductivity technology, applied in the field of aluminum alloy material processing, can solve the problems of unguaranteed size, increased enterprise cost, low thermal conductivity, etc., to eliminate lattice distortion, improve mucosal properties, and improve thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

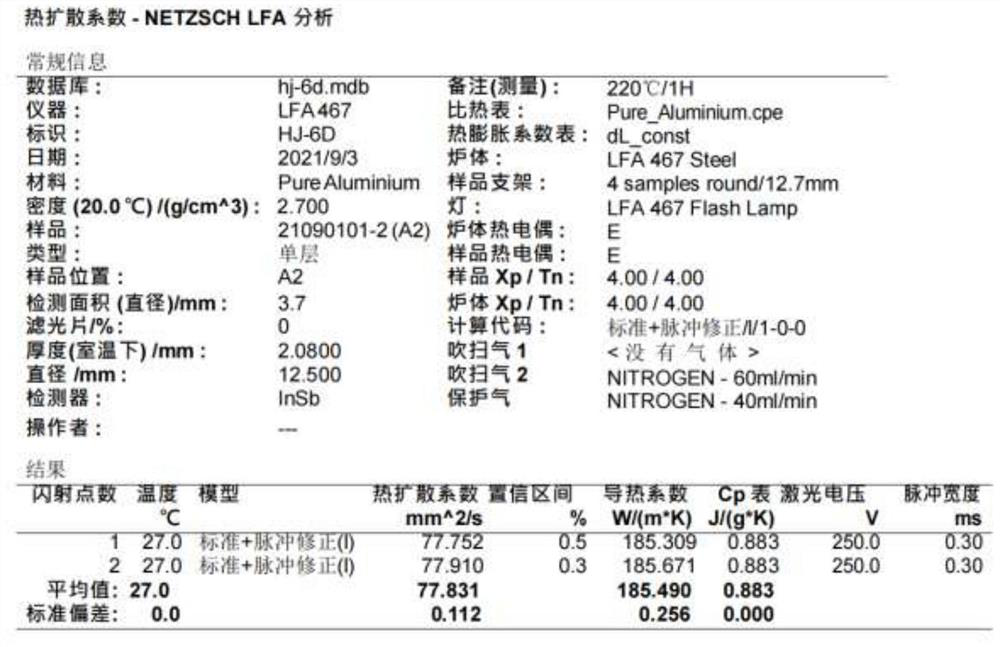

Embodiment 1

[0047] Embodiment 1. A high-strength and high-thermal-conductivity aluminum alloy material. The high-strength and high-thermal-conductivity aluminum alloy material includes the following components by mass percentage: Si: 4.5%, Mg: 0.3%, Fe: 0.7%, B: 0.01%, Sr: 0.01%, (Mn+Ti+V+Cr): 0.01%, aluminum: 94.47%.

[0048]

[0049] A heat treatment process for a high-strength and high-thermal-conductivity aluminum alloy material, comprising the following steps:

[0050] S1. Put 85% pure aluminum ingots into the heating furnace and heat to 850℃;

[0051] S2. The heating furnace is maintained at 850°C, and crystalline silicon, aluminum boron master alloy and 75% iron metal powder additives are added;

[0052] S3. After the material of the heating furnace is completely melted, add the remaining 15% pure aluminum ingot to cool down;

[0053] S4, when the heating furnace is cooled to 700 ℃, pure magnesium metal material is added;

[0054] S5. After all the raw materials in the heatin...

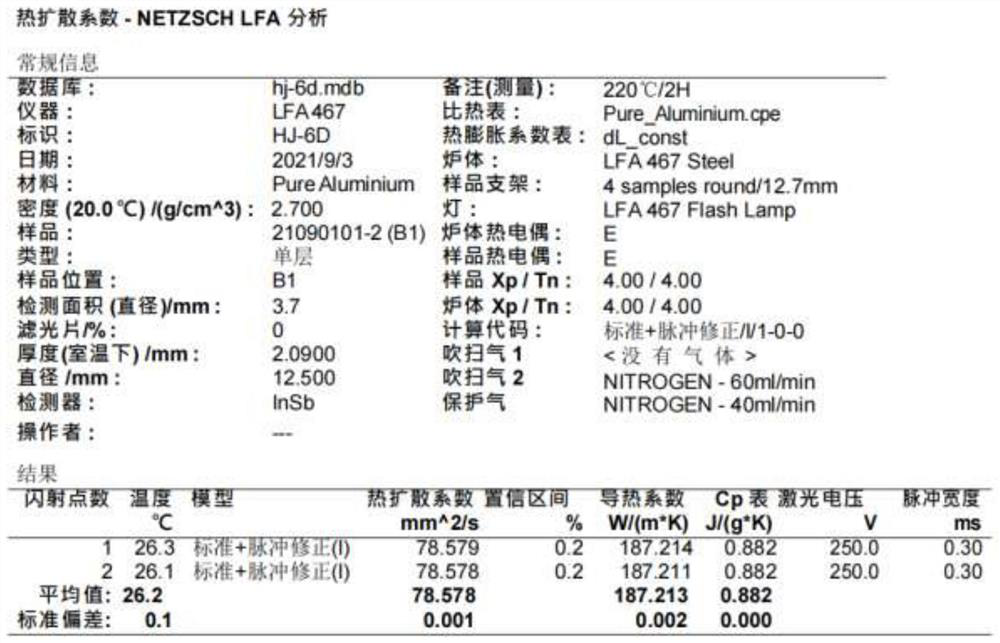

Embodiment 2

[0059]Embodiment 2. A high-strength and high-thermal-conductivity aluminum alloy material, the high-strength and high-thermal-conductivity aluminum alloy material includes the following components by mass percentage: Si: 6.5%, Mg: 0.6%, Fe: 1.0%, B: 0.03%, Sr: 0.04%, (Mn+Ti+V+Cr): 0.02%, Aluminum: 91.81%.

[0060]

[0061] A heat treatment process for a high-strength and high-thermal-conductivity aluminum alloy material, comprising the following steps:

[0062] S1. Put 85% pure aluminum ingots into the heating furnace and heat to 850℃;

[0063] S2. The heating furnace is maintained at 850°C, and crystalline silicon, aluminum boron master alloy and 75% iron metal powder additives are added;

[0064] S3. After the material of the heating furnace is completely melted, add the remaining 15% pure aluminum ingot to cool down;

[0065] S4, when the heating furnace is cooled to 700 ℃, pure magnesium metal material is added;

[0066] S5. After all the raw materials in the heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com