Water-containing undisturbed shield slag non-fired building material and preparation method thereof

A technology for building materials and shield slag, used in chemical instruments and methods, cement production, sustainable waste treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

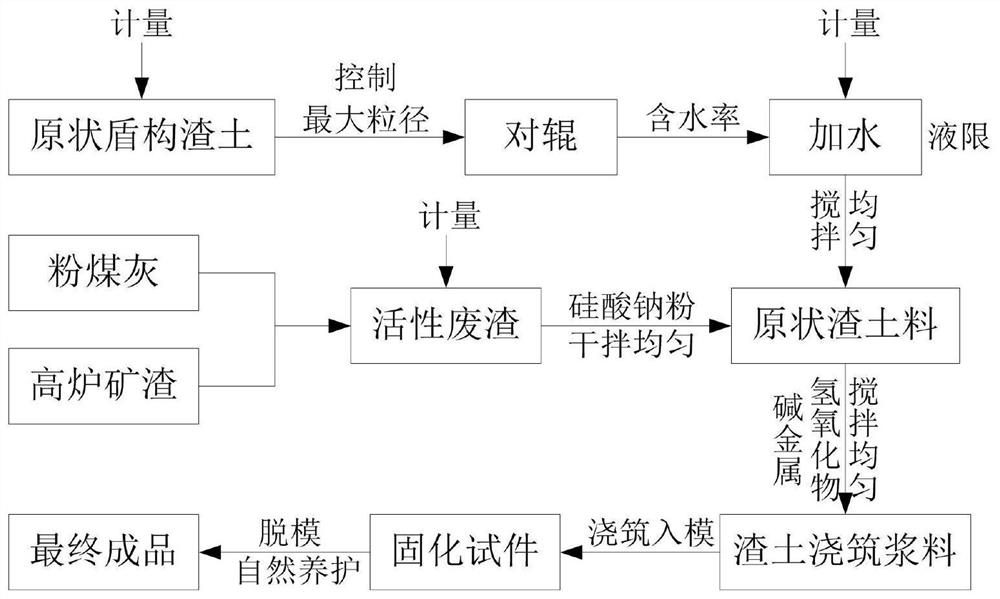

Method used

Image

Examples

Embodiment 1

[0088] The water-containing undisturbed shield slag unburned brick in this embodiment is prepared through the following steps:

[0089] Weigh 70 parts of water-containing original shield slag (by dry weight), 30 parts of blast furnace slag, 4 parts of sodium hydroxide solid, 7.5 parts of solid sodium silicate powder, and 15.4 parts of water; The type is moderately weathered conglomerate shield slag with a moisture content of 23%, which is taken from a certain section of Changsha Metro Line 3; the particle size of the blast furnace slag is above 200 mesh; The purity is 99%; the modulus of sodium silicate powder is 2.85, and the fineness is 100 mesh.

[0090] Mix 30 parts of blast furnace slag and 7.5 parts of solid sodium silicate powder in a mixer; take 70 parts of undisturbed weathered conglomerate shield slag, add 15.4 parts of water, and add blast furnace slag and solid sodium silicate powder that are well stirred The mixture is crushed and mixed with a rotary wheel mill, ...

Embodiment 2

[0093] The water-containing undisturbed shield slag unburned brick in this embodiment is prepared through the following steps:

[0094] Weigh 70 parts of water-containing original shield slag (by dry weight), 30 parts of blast furnace slag, 4.0 parts of sodium hydroxide solid, 6.0 parts of solid sodium silicate powder, and 14.5 parts of water; The type is strongly weathered slate shield slag with a moisture content of 36%, which is taken from a certain section of Changsha Metro Line 6; the particle size of the blast furnace slag is above 200 mesh; The purity is 99%; the modulus of sodium silicate powder is 2.85, and the fineness is 100 mesh.

[0095] Mix 30 parts of blast furnace slag and 6.0 parts of solid sodium silicate powder in a mixer; take 70 parts of undisturbed strongly weathered slate shield slag, add 14.5 parts of water, and add the well-stirred blast furnace slag and solid sodium silicate powder The mixture is crushed and mixed with a rotary wheel mill, and the co...

Embodiment 3

[0098] The water-containing undisturbed shield slag non-burning test piece in this embodiment is obtained through the following steps:

[0099] The water-containing undisturbed shield muck is taken from the moderately weathered conglomerate muck on the left line of a certain section of Changsha Metro Line 3, and its moisture content is 23%. Weigh 70 parts of water-containing original shield slag (by dry weight), 30 parts of fly ash, 4.09 parts of sodium hydroxide solid, 7.54 parts of solid sodium silicate powder, and 31.5 parts of water; the particle size of fly ash is 200 above mesh; sodium hydroxide is analytically pure in the form of industrial-grade solid flakes, with a purity of 99%; the modulus of sodium silicate powder is 2.85, and the fineness is 100 mesh.

[0100] Mix 30 parts of fly ash and 7.54 parts of solid sodium silicate powder in a mixer; take 70 parts of undisturbed weathered conglomerate shield muck, add 31.5 parts of water, and add the well-stirred fly ash a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com